Lead-free low-melting-point glass with excellent comprehensive performance and application method thereof

A technology with low melting point glass and comprehensive performance, applied in the field of lead-free low melting point glass and glass materials, can solve the problems of limited sealing applications, high thermal expansion coefficient, high glass melting temperature, etc., achieve broad market development prospects, and simple preparation method , excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

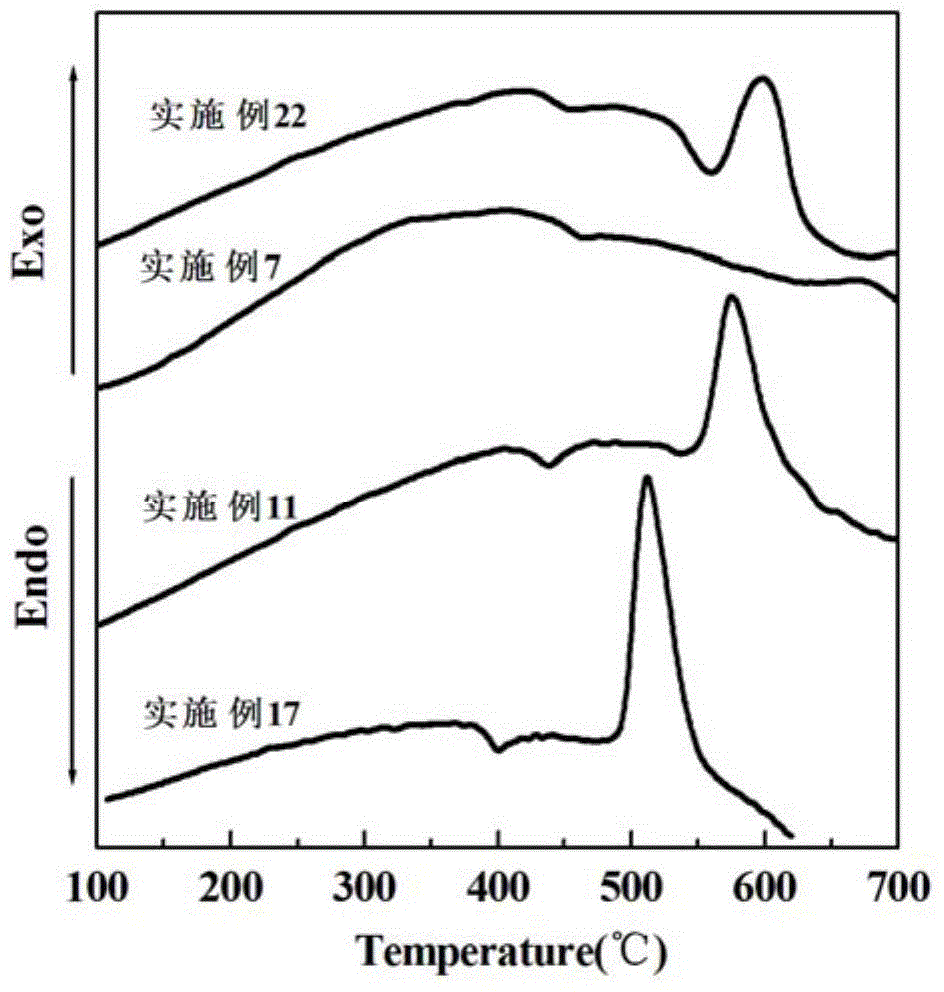

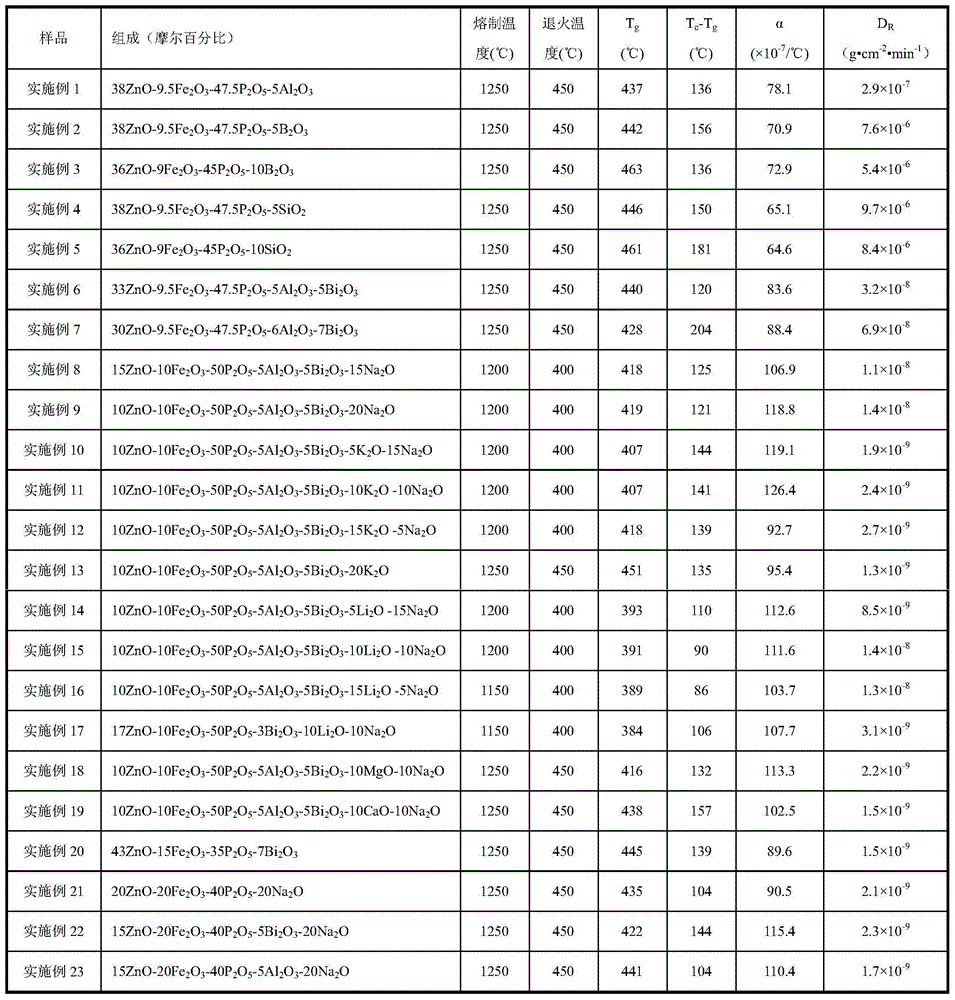

[0029] The glass of embodiment 1 is used as sealing glass, then thermal stability and chemical stability can all meet the requirements, but its transition temperature is slightly higher and unfavorable for sealing application; If this glass is used to solidify high-level radioactive waste, then chemical stability is far from being able to meet the requirements. Meet the requirements, not up to the existing 40Fe 2 o 3 -60P 2 o 5 glass level. Therefore we have studied Bi on the basis of embodiment 1 again afterwards 2 o 3 and MoO 3 Effect of doping on its performance. Mix 10mol% Bi in the proportioning of embodiment 1 2 o 3 Can not be glass; mixed with a small amount of Bi 2 o 3 The chemical stability of the prepared glass of Examples 6 and 7 is sharply improved, and the change in transition temperature is small; the addition of 5mol% MoO 3 The thermal stability of the prepared glass is significantly improved, but the chemical stability is reduced instead. Therefore,...

Embodiment 6

[0030] Though embodiment 6 and 7 glass have high chemical stability and high thermal stability, its T g There is still a certain distance from the target value of 400°C. After slightly adjusting the composition of the glass in Example 6, we tried to pass Na 2 O doping to lower the transition temperature of the glass. Formulated (30-x)ZnO-10Fe 2 o 3 -50P 2 o 5 -5Al 2 o 3 -5Bi 2 o 3 -xNa 2 Among the six formulations of O(x=0,5,10,15,20,30), glass cannot be prepared when x=30, and glass performance is better when x=15 and 20, corresponding to Example 8 in Table 1 respectively and 9. Compared with embodiment 6, the thermostability and chemical stability of embodiment 8 and 9 change little, but T g value has decreased significantly.

[0031] On the basis of Example 9, we also use the mixed alkali effect to regulate the performance of the glass, respectively studied the K 2 O-Na 2 O and Li 2 O-Na 2 O mixed base effect. Prepared 10ZnO-10Fe 2 o 3 -50P 2 o 5 -5Al ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com