A carbon coating method for quartz ampoules used for crystal growth

A quartz ampoule and crystal growth technology, applied in the direction of coating, etc., can solve the problems of long carbon plating time, low carbon content of carbon source, complicated operation procedures, etc., to improve carbon plating efficiency, simple carbon plating requirements, simplify gas The effect of the road device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

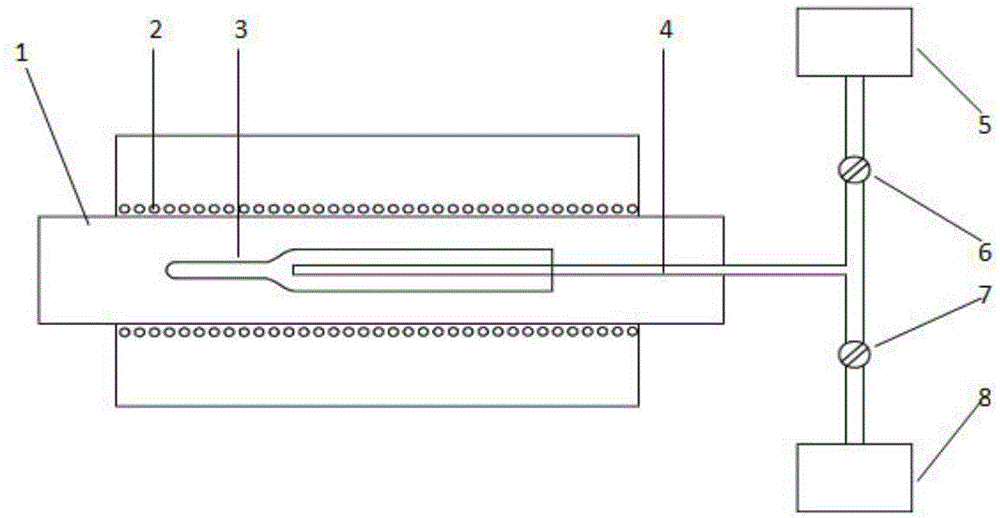

[0032] Place the quartz ampoule to be carbonized in the tube furnace: put the quartz ampoule 3 to be carbonized into the carbon coating temperature zone in the tube 1 of the tube furnace (after the tube furnace is heated up, the temperature in the furnace is 900-1000°C area, this temperature is obtained by the temperature field test in the furnace), after the carbon plating position is determined, the vent tube 4 is put into the quartz ampoule 3, and the vent tube nozzle is positioned at 30 millimeters away from the quartz ampoule tail.

[0033] Heat up the tube furnace and exhaust the air: raise the furnace temperature to 900°C at a rate of 5°C / min under normal pressure, keep it warm for 30 minutes after reaching the temperature, open the inert gas controller 5, and open the inert gas pipeline valve 6-way Nitrogen gas with a purity of more than 99.99% is passed through the quartz ampoule 3 to remove residual air, the gas flow rate is 70 ml / min, and the nitrogen gas flow time i...

Embodiment 2

[0037] Place the quartz ampoule to be carbonized in the tube furnace: put the quartz ampoule 3 to be carbonized into the carbon coating temperature zone in the tube 1 of the tube furnace (after the tube furnace is heated up, the temperature in the furnace is 900-1000°C area, this temperature is obtained by the temperature field test in the furnace), after the carbon plating position is determined, the vent tube 4 is put into the quartz ampoule 3, and the vent tube nozzle is positioned at 30 millimeters away from the quartz ampoule tail.

[0038] Heat up the tube furnace and exhaust air: raise the furnace temperature to 950°C at a rate of 6°C / min under normal pressure, keep it warm for 30 minutes after reaching the temperature, open the inert gas controller 5, and open the 6-way valve of the inert gas pipeline Argon gas with a purity of more than 99.99% is passed through the quartz ampoule 3 to remove residual air, the gas flow rate is 70 ml / min, and the time for passing argon g...

Embodiment 3

[0042] Place the quartz ampoule to be carbonized in the tube furnace: put the quartz ampoule 3 to be carbonized into the carbon coating temperature zone in the tube 1 of the tube furnace (after the tube furnace is heated up, the temperature in the furnace is 900-1000°C area, this temperature is obtained by the temperature field test in the furnace), after the carbon plating position is determined, the vent tube 4 is put into the quartz ampoule 3, and the vent tube nozzle is positioned at 30 millimeters away from the quartz ampoule tail.

[0043] Heat up the tube furnace and exhaust the air: raise the furnace temperature to 1000°C at a rate of 8°C / min under normal pressure, keep it warm for 30 minutes after reaching the temperature, open the inert gas controller 5, and open the inert gas pipeline valve 6-way Nitrogen gas with a purity of more than 99.99% is passed through the quartz ampoule 3 to remove residual air, the gas flow rate is 70 ml / min, and the nitrogen gas flow time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com