Concrete with high water reducing rate, water reducing agent used and preparation method thereof

A concrete water-reducing agent and water-type technology, which is applied in the field of concrete with high water-reducing rate, can solve the problems of sensitive dosage, poor mud tolerance, etc., and achieves easy operation, small loss over time, and good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

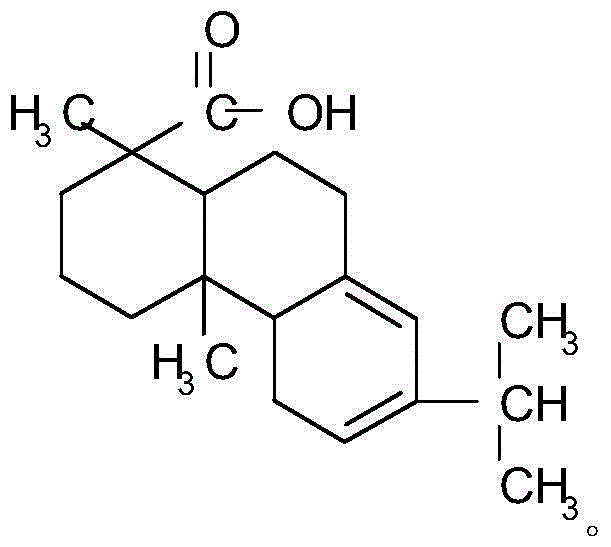

Image

Examples

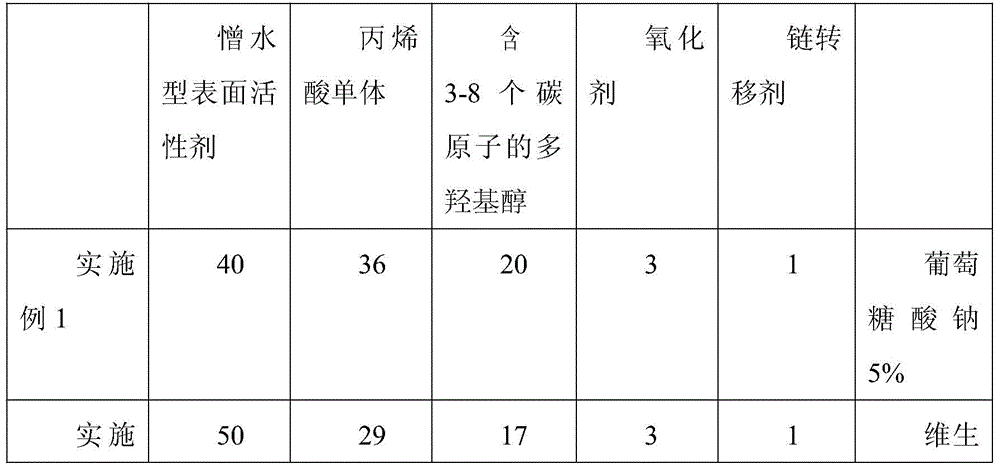

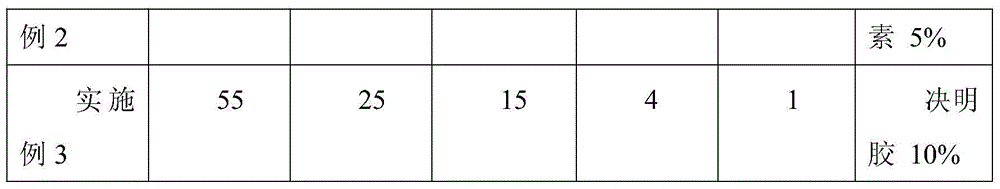

Embodiment 1-3

[0027] According to the composition of Table 1, the hydrophobic polymer concrete water reducer is prepared, and the steps include:

[0028]

[0029]

[0030] (1) Add polyhydric alcohol containing 3-8 carbon atoms to acrylic acid monomer, then add catalyst sodium dodecylbenzenesulfonate, heat to dissolve, and then perform esterification reaction at 90-105°C for 4-7h , make acrylate; Wherein, the molar ratio of polyhydric alcohol and acrylic acid monomer is 1:2-4;

[0031] (2) Add deionized water to the product of step (1), heat it to fully dissolve, and make a reaction bottom solution; then add hydrophobic surfactant and chain transfer agent, and stir at 50-60°C Add hydrogen peroxide dropwise for copolymerization reaction, the reaction time is 2-3 hours, then keep warm at 25-30°C and continue to stir for 1 hour; finally use sodium hydroxide aqueous solution to adjust the pH value to 7-8 to obtain a solid content of 35-40%. Hydrophobic polymer concrete superplasticizer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com