Blast-furnace taphole stemming prepared from ferrotitanium slag and preparation method of blast-furnace taphole

A blast furnace tapping and ferrotitanium slag technology is applied in the field of refractory materials, which can solve the problems of good corrosion resistance and high service life of the titanium-iron type tap hole taphole mud, so as to improve the blast furnace smelting efficiency, reduce the consumption of refractory materials, and reduce the expansion rate. Effect of Pore Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

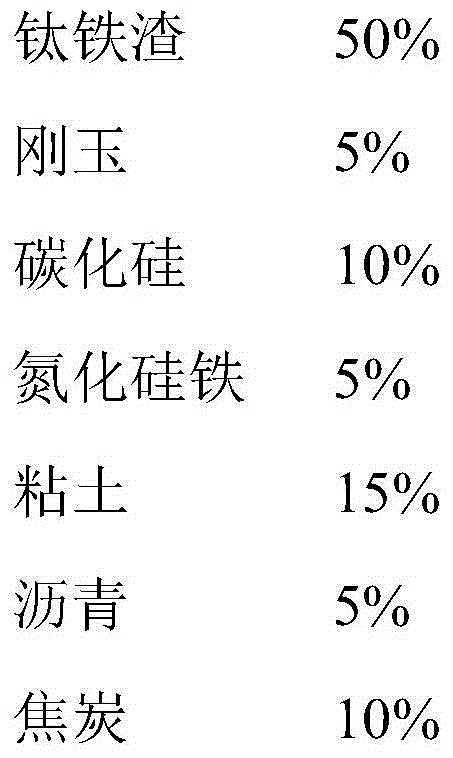

[0015] A 1080m ferro-titanium slag 3 The blast furnace tap hole clay 1 is composed of the following components by weight percentage:

[0016]

[0017] The blast furnace tap hole clay is also added with 20% of an additional binder according to the mass percentage of the blast furnace tap hole clay.

[0018] Preparation method: put all the above-mentioned raw materials into a mixer, pre-mix for 3 minutes, add 95% of the total amount of binder, and mix and grind for 30 minutes, then test the product's Masha value, the qualified range is 500-700KPa, and it is discarded if it is lower than 500KPa , when it is higher than 700KPa, finally gradually add the remaining 5% of the external binder to adjust the Masha value to the acceptable range, mix and grind for 10 minutes, and discharge the material, which is formed by the extruder and packaged, which is the finished product. The horsesia value of the product is controlled at 500Kpa.

Embodiment 2

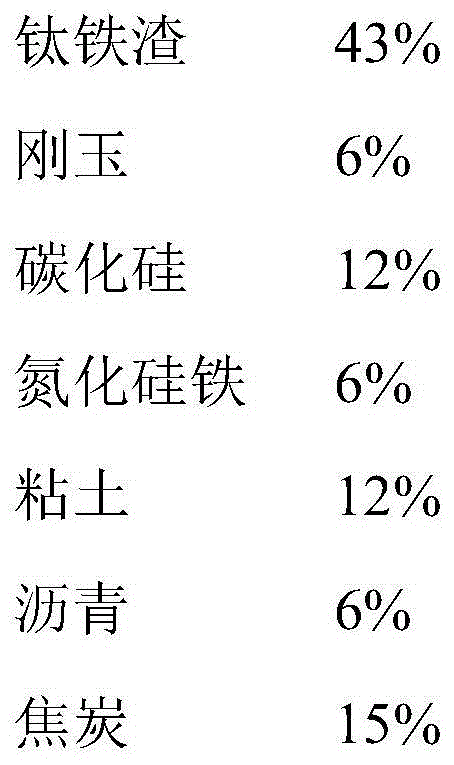

[0020] A kind of 1800m ferro-titanium slag 3 The blast furnace tap hole clay 2 is composed of the following components by weight percentage:

[0021]

[0022] The blast furnace taphole clay is also added with an additional binder of 18% according to the mass percentage of the blast furnace taphole clay.

[0023] Preparation method: Put all the above-mentioned raw materials into a mixer, pre-mix for 2 minutes, add 95% of the total amount of binder, mix and grind for 30 minutes, test the product's Masha value, the qualified range is 700-900KPa, and it is discarded if it is lower than 700KPa , when it is higher than 900KPa, finally gradually add the remaining 5% of the external binder to adjust the Masha value to the acceptable range, mix and grind for 10 minutes, then discharge the material, shape it through the extruder, and pack it, which is the finished product. The horsesia value of the product is controlled at 800Kpa.

Embodiment 3

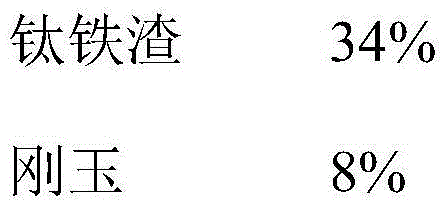

[0025] A 2200m ferro-titanium slag 3 The blast furnace tap hole clay 3 is composed of the following components in weight percentage:

[0026]

[0027]

[0028] The blast furnace taphole mud is also added with an additional binder of 16% according to the mass percentage of the blast furnace taphole mud.

[0029] Preparation method: Put all the above-mentioned raw materials into the mixer, pre-mix for 5 minutes, add 92% of the total amount of binder, mix and grind for 28 minutes, test the product's Masha value, the qualified range is 900-1100KPa, and it is discarded if it is lower than 900KPa , when it is higher than 1100KPa, finally gradually add the remaining 8% of the external binder to adjust the Masha value to the acceptable range, mix and grind for 5 minutes, then discharge the material, shape it through the extruder, and pack it, which is the finished product. The horsesia value of the product is controlled at 1000Kpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com