Preparation method of diammonium hydrogen citrate

A technology of diammonium hydrogen citrate and citric acid, applied in the field of food additives, can solve the problems of exhaust gas emission, many materials, large energy consumption, etc., and achieve the effect of avoiding decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

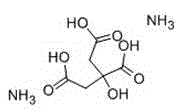

Image

Examples

specific Embodiment 1

[0029] A preparation method of diammonium hydrogen citrate, comprising the steps of:

[0030] Step (1), using edible citric acid and liquid ammonia as raw materials;

[0031] Step (2), dissolving edible citric acid in water to prepare a solution with a concentration of 39%;

[0032] In step (3), the liquid ammonia is passed into the citric acid aqueous solution, and the liquid ammonia is slowly added to control the pH value of the solution to be within the range of 4.5;

[0033] Step (4), air-cool the above materials to 19°C, until a large amount of diammonium hydrogen citrate crystallizes out, and separates from the mother liquor through a centrifuge to obtain crystals of diammonium hydrogen citrate;

[0034] In step (5), send the crystals of diammonium hydrogen citrate to a drying oven at 62°C for 45 minutes to obtain diammonium hydrogen citrate;

[0035] In step (6), continue to dissolve the remaining mother liquor in edible citric acid for recycling.

specific Embodiment 2

[0036] A preparation method of diammonium hydrogen citrate, comprising the steps of:

[0037] Step (1), using edible citric acid and liquid ammonia as raw materials;

[0038] Step (2), dissolving edible citric acid in water to prepare a solution with a concentration of 51%;

[0039] In step (3), the liquid ammonia is passed into the citric acid aqueous solution, and the liquid ammonia is slowly added to control the pH value of the solution to be within the range of 5.5;

[0040] Step (4), air-cool the above materials to 27°C until a large amount of diammonium hydrogen citrate crystallizes, and separate from the mother liquor through a centrifuge to obtain crystals of diammonium hydrogen citrate;

[0041] Step (5), sending the diammonium hydrogen citrate crystals to a drying oven at 70°C for 60 minutes to obtain diammonium hydrogen citrate;

[0042] In step (6), continue to dissolve the remaining mother liquor in edible citric acid for recycling.

specific Embodiment 3

[0043] A preparation method of diammonium hydrogen citrate, comprising the steps of:

[0044] Step (1), using edible citric acid and liquid ammonia as raw materials;

[0045] Step (2), dissolving edible citric acid in water to prepare a solution with a concentration of 47%;

[0046] In step (3), the liquid ammonia is passed into the citric acid aqueous solution, and the liquid ammonia is slowly added to control the pH value of the solution to be within the range of 5.1;

[0047] Step (4), air-cool the above materials to 23°C until a large amount of diammonium hydrogen citrate crystallizes out, and separates from the mother liquor through a centrifuge to obtain crystals of diammonium hydrogen citrate;

[0048] Step (5), sending the diammonium hydrogen citrate crystals to a drying oven at 64°C for 56 minutes to obtain diammonium hydrogen citrate;

[0049] In step (6), continue to dissolve the remaining mother liquor in edible citric acid for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com