Synthetic method of heat-resistant polyurethane elastomer

A technology of polyurethane elastomer and synthesis method, which is applied in the field of polyurethane elastomer, can solve the problems of accelerated aging and performance degradation of polyurethane, and achieve the effect of high performance retention rate and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

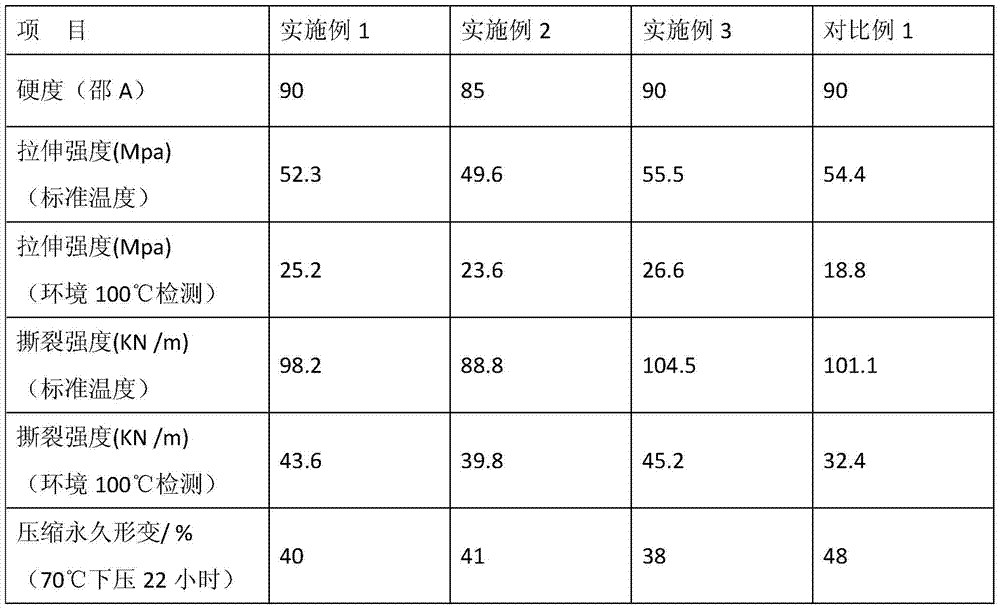

Examples

Embodiment 1

[0020] Synthesis of polyester polyol: adipic acid: 66.2wt%, ethylene glycol: 32.4wt%, trimethylolpropane: 1.4wt%, plus catalyst tetrabutyl titanate 50ppm synthetic molecular weight is 1500 polyester polyol A .

[0021] The specific steps are: add adipic acid, ethylene glycol, trimethylolpropane and tetrabutyl titanate into the reaction kettle for heating, and protect it with nitrogen gas. When the temperature rises to 140°C, water will be reacted, and the reflux tower will be controlled. The top temperature is 100-102°C, then slowly increase the temperature of the kettle to 160-180°C, keep it warm for 2-3 hours, then raise the temperature to 220-230°C, when the water is finished, keep it warm for 2-3 hours, and then use nitrogen The bubbling process removes the moisture produced by polycondensation. When the acid value of the material in the kettle is less than 0.4mgKOH / g and the moisture content is below 0.05%, the product is qualified, and the material is cooled and discharg...

Embodiment 2

[0024] According to the preparation method of embodiment 1.

[0025] Synthesis of polyester polyol: adipic acid: 58wt%, butanediol: 40.5wt%, trimethylolpropane: 1.5wt%, plus catalyst tetrabutyl titanate 50ppm to synthesize polyester polyol B with a molecular weight of 2000.

[0026] Synthesis of heat-resistant polyurethane elastomer: In terms of weight percentage, take polyester polyol B: 85.1%, TDI‐80: 14.9%, react at 80°C for 3 hours, remove air bubbles in vacuum, take samples to detect isocyanate content, and detect‐NCO The content is 3.6%, and the polyurethane prepolymer is obtained, and the ratio of the polyurethane prepolymer and MOCA is 100:10.3, and the polyurethane elastomer product with a hardness of Shore 85A is obtained by conventional methods.

Embodiment 3

[0028] Polyester polyol adopts the preparation method of embodiment 2 to prepare polyester polyol B.

[0029] Synthesis of heat-resistant polyurethane elastomer: In terms of weight percentage, take polyester polyol B: 69.1%, MDI-100: 30.9%, react at 80°C for 3 hours, remove air bubbles in vacuum, take samples to detect isocyanate content, and detect-NCO The content is 7.5%, and the polyurethane prepolymer is obtained, and the ratio of the polyurethane prepolymer and butanediol is 100:7.6, and the polyurethane elastomer product with a hardness of Shore 90A is obtained by conventional methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com