Direct-current cable insulation material

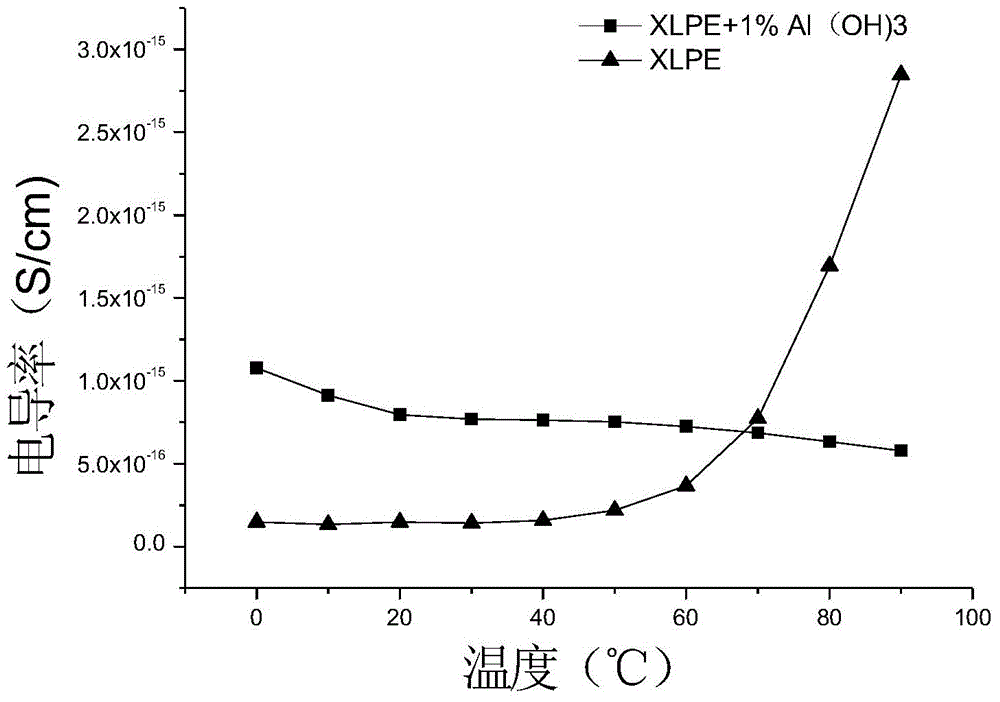

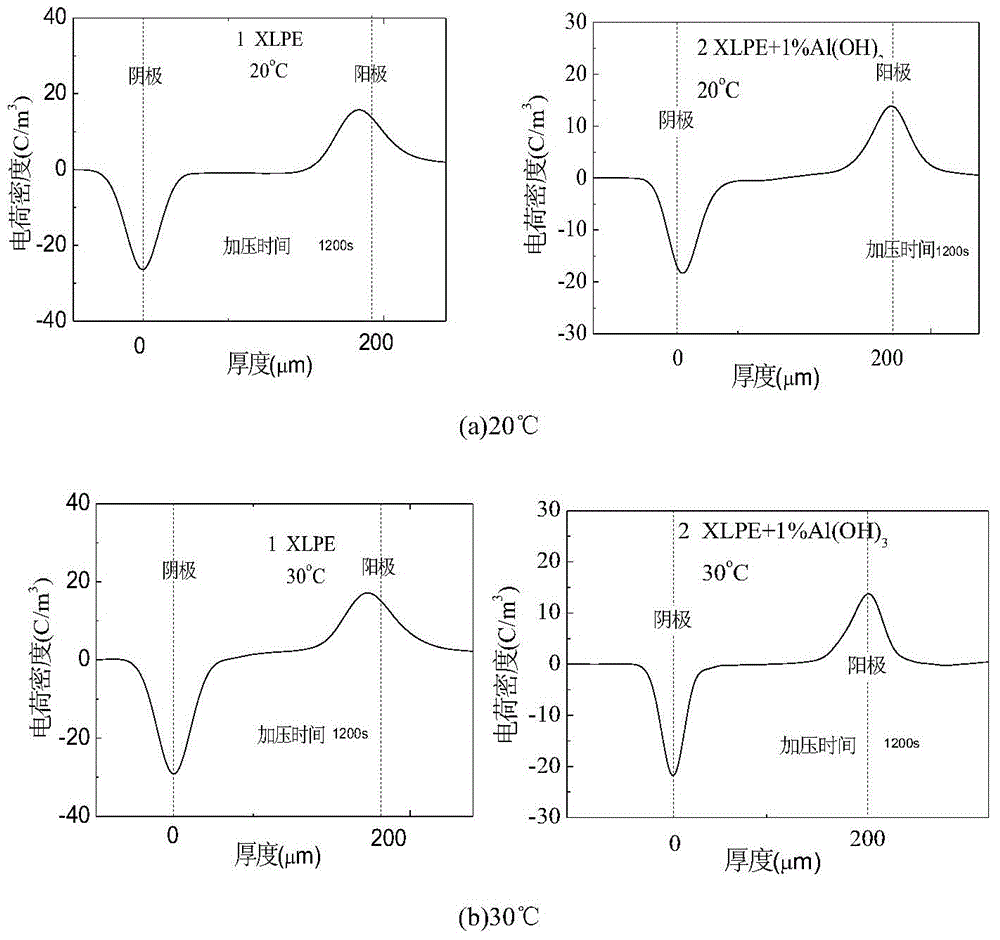

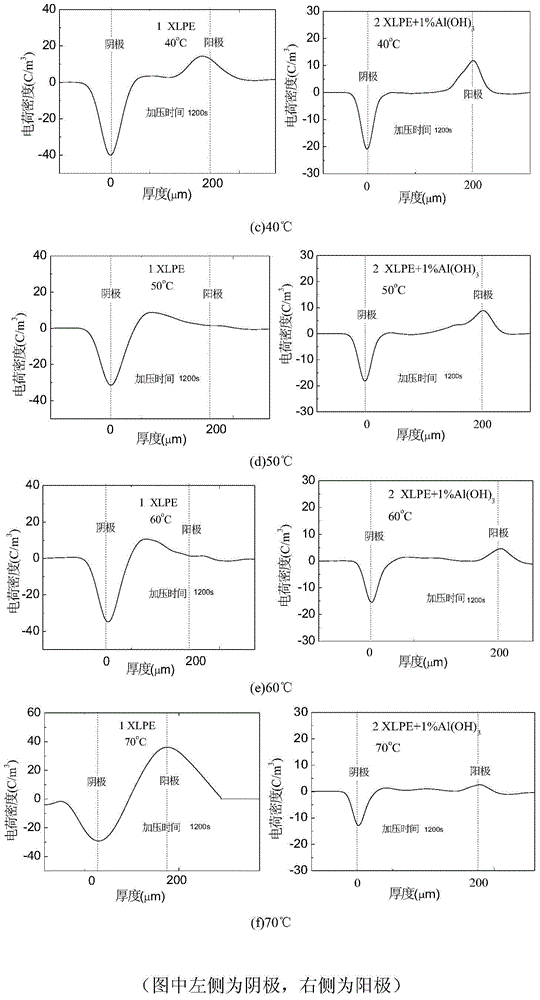

A technology of insulating materials and DC cables, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve problems such as high local field strength and insulation failure, achieve good insulation performance, excellent electrical conductivity, and suppress space charge cumulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of the DC cable insulating material comprises the following steps:

[0023] Step 1, take by weight 100 parts of low-density polyethylene, 0.5 parts of 4,4'-thiobis(6-tert-butyl-3-methylphenol), 2.5 parts of dicumyl peroxide and 2.5 parts of nano aluminum hydroxide. The nano-aluminum hydroxide is modified nano-aluminum hydroxide particles, which are obtained by modifying the nano-aluminum hydroxide particles with a silane coupling agent, dissolving them in cyclohexane, and evaporating and drying them. The mass ratio of the nano aluminum hydroxide particles to the silane coupling agent is 5:100. The average particle size of the nano-aluminum hydroxide is 30±5nm, and the specific surface area is 180±30m 2 / g. The low-density polyethylene has a melt index of 0.8-12g / 10min and a density of 0.90-0.925g / cm 3 .

[0024] Step 2. Add the low-density polyethylene, antioxidant and nano-aluminum hydroxide weighed in step 1 into a twin-screw mixer at the s...

Embodiment 2

[0028] The preparation method of the DC cable insulating material comprises the following steps:

[0029] Step 1, take by weight 100 parts of low-density polyethylene, 0.5 parts of 4,4'-thiobis(6-tert-butyl-3-methylphenol), 2.5 parts of dicumyl peroxide and 1.5 parts of nano aluminum hydroxide. The nano-aluminum hydroxide is modified nano-aluminum hydroxide particles, which are obtained by modifying the nano-aluminum hydroxide particles with a silane coupling agent, dissolving them in cyclohexane, and evaporating and drying them. The mass ratio of the nano aluminum hydroxide particles to the silane coupling agent is 5:100. The average particle size of the nano-aluminum hydroxide is 30±5nm, and the specific surface area is 180±30m 2 / g. The low-density polyethylene has a melt index of 0.8-12g / 10min and a density of 0.90-0.925g / cm 3 .

[0030] Step 2. Add the low-density polyethylene, antioxidant and nano-aluminum hydroxide weighed in step 1 into a twin-screw mixer at the s...

Embodiment 3

[0034] The preparation method of the DC cable insulating material comprises the following steps:

[0035] Step 1, take by weight 100 parts of low-density polyethylene, 0.5 parts of 4,4'-thiobis(6-tert-butyl-3-methylphenol), 2 parts of dimethylphthalein peroxide and 2 parts Parts of nano aluminum hydroxide. The nano-aluminum hydroxide is modified nano-aluminum hydroxide particles, which are obtained by modifying the nano-aluminum hydroxide particles with a silane coupling agent, dissolving them in cyclohexane, and evaporating and drying them. The mass ratio of the nano aluminum hydroxide particles to the silane coupling agent is 5:100. The average particle size of the nano-aluminum hydroxide is 30±5nm, and the specific surface area is 180±30m 2 / g. The low-density polyethylene has a melt index of 0.8-12g / 10min and a density of 0.90-0.925g / cm 3 .

[0036] Step 2. Add the low-density polyethylene, antioxidant and nano-aluminum hydroxide weighed in step 1 into a twin-screw mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com