Polycarbonate alloy material and preparation method thereof

A technology for polycarbonate and alloy materials, applied in the field of polycarbonate alloy materials and their preparation, can solve the problems of low degree of freedom in structural design, general formability, high cost, etc., and achieves high degree of freedom in structural design and low cost , The effect of good molding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 3

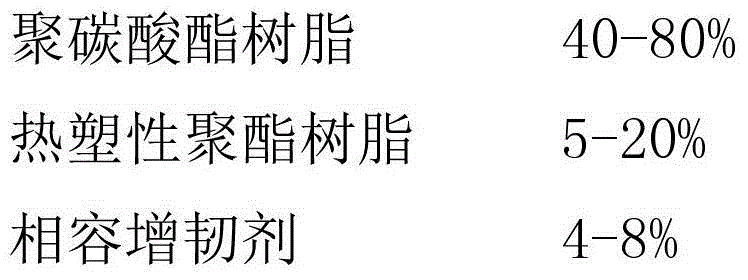

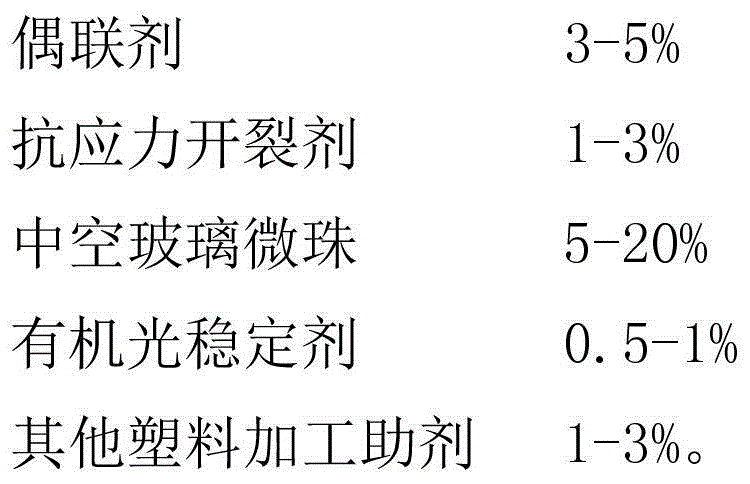

[0046] Further, the embodiments of the present invention propose embodiments 1-3, as shown in Table 1:

[0047]

[0048] Table 1

[0049] In the above-mentioned implementation of the examples of the present invention, the following materials were used:

[0050] The polycarbonate resin is PC 141R produced by Sabic Company of Saudi Arabia;

[0051] Thermoplastic polyester resin adopts PBT 1100 produced by Taiwan Changchun Company;

[0052] Hollow glass beads adopt soda lime borosilicate glass beads brand S32 produced by 3M Company in the United States;

[0053] Anti-stress cracking agent adopts domestic ESC-3008;

[0054] The coupling agent is the silane coupling agent KH570 produced by Dow Corning;

[0055] The organic light stabilizer is a compound of hindered amine light stabilizer HALS-119 and benzotriazole ultraviolet absorber UV-329 produced by Clariant, Germany;

[0056] Plastic processing aids include antioxidants, high flow modifiers and lubricants, among which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com