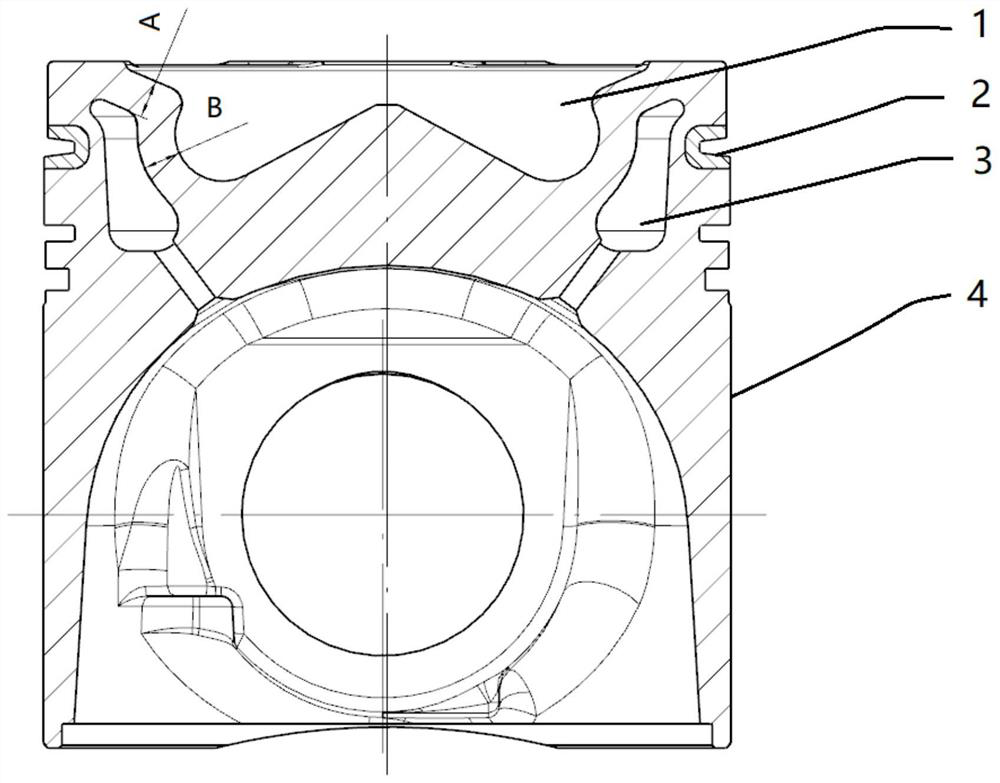

Conformal soluble preform for internal combustion engine piston and piston manufacturing method

A manufacturing method and technology for preforms, which are applied in the directions of pistons, manufacturing tools, mechanical equipment, etc., can solve the problems of reducing the temperature of the combustion chamber and the first ring groove, unfavorable for large-scale industrial applications, and lack of pressing molds, and achieve the cooling effect. The same effect, large degree of freedom, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

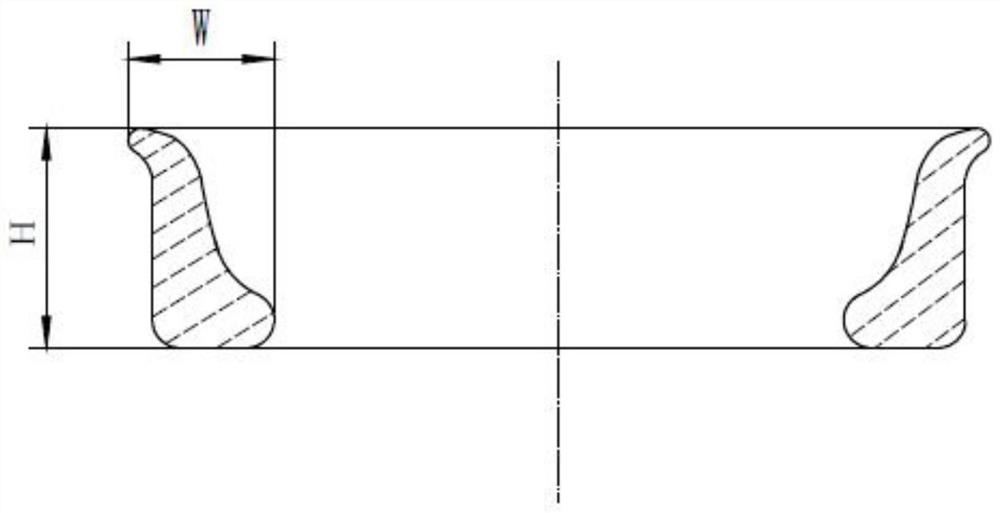

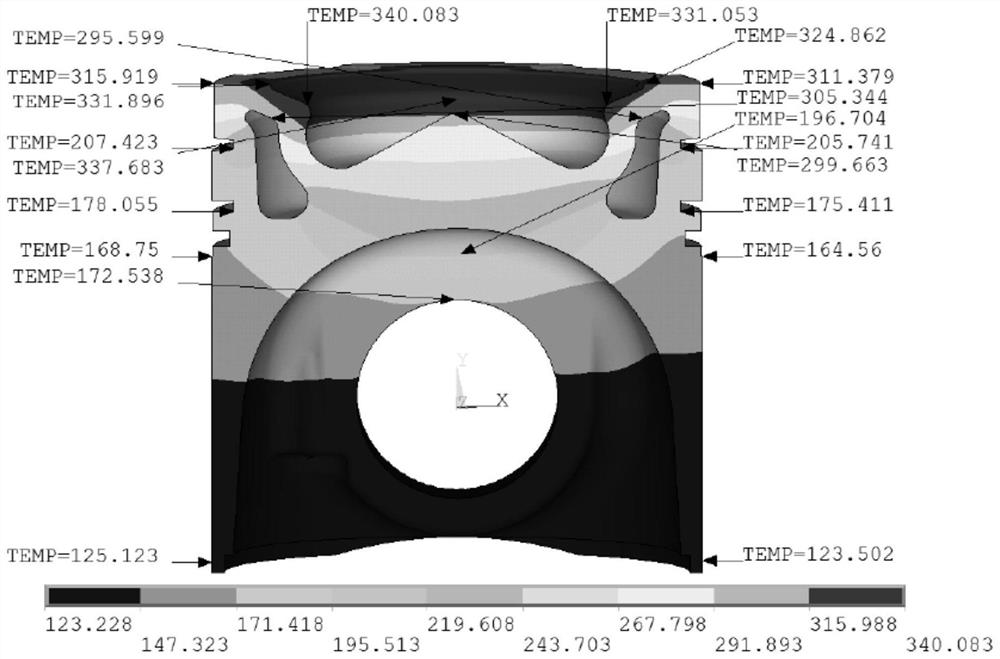

Method used

Image

Examples

Embodiment 1

[0057] Conformal internal cooling soluble preform material composition: Na 2 CO 3 : 25%, mullite powder: 2%, aluminum titanate powder: 2%, alumina fiber: 2%, and the balance is NaCl.

[0058] It is mainly achieved through the following steps:

[0059] (1) NaCl and Na 2 CO 3 Add it into the silicon carbide anti-corrosion crucible according to the proportion and heat it until it melts, and the temperature is controlled at 800°C;

[0060] (2) Add the ground mullite powder and aluminum titanate powder according to the ratio, and keep warm for 10 minutes;

[0061] (3) Add zirconium-rich alumina fibers with a content of 1%, mechanically stir for 1 min, and then pour into a preheated mold to obtain a conformal soluble preform;

[0062] (4) The conformal soluble preform after deburring is cast into the piston through a gravity casting process, and then the preform is dissolved with water to obtain an internal combustion engine piston with a conformal internal cooling oil chamber....

Embodiment 2

[0064] Conformal internal cooling soluble preform material composition: Na 2 CO 3 : 35%, mullite powder: 5%, aluminum titanate powder: 6%, alumina fiber: 3%, and the balance is NaCl.

[0065] It is mainly achieved through the following steps:

[0066] (1) NaCl and Na 2 CO 3 Add it into the silicon carbide anti-corrosion crucible according to the proportion and heat until it melts, and the temperature is controlled at 820°C;

[0067] (2) Add the ground mullite powder and aluminum titanate powder according to the ratio, and keep warm for 15 minutes;

[0068] (3) Add zirconium-rich alumina fibers with a content of 2%, mechanically stir for 2 minutes, and then pour into a preheated mold to obtain a conformal soluble preform;

[0069] (4) The conformal soluble preform after deburring is cast into the piston through a 1MPa pressure casting process, and then the preform is dissolved with water to obtain the internal combustion engine piston with a conformal internal cooling oil ...

Embodiment 3

[0071] Conformal internal cooling soluble preform material composition: Na 2 CO 3 : 30%, mullite powder: 6%, aluminum titanate powder: 10%, alumina fiber: 6%, and the balance is NaCl.

[0072] It is mainly achieved through the following steps:

[0073] (1) NaCl and Na 2 CO 3 Add it into the silicon carbide anti-corrosion crucible according to the proportion and heat it until it melts, and the temperature is controlled at 860°C;

[0074] (2) Add the ground mullite powder and aluminum titanate powder according to the ratio, and keep warm for 20 minutes;

[0075] (3) adding zirconium-rich alumina fibers with a content of 3%, mechanically stirring for 3 minutes, and then pouring into a preheated mold to obtain a conformal soluble preform;

[0076] (4) The conformal soluble preform after deburring is cast into the piston through a die casting process with a pressure of 10 MPa, and then the preform is dissolved with water to obtain an internal combustion engine piston with a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com