Mineral powder grinding aid

A technology of grinding aid and mineral powder, applied in the field of mineral powder grinding aid, can solve the problems such as insufficient activity and poor grindability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

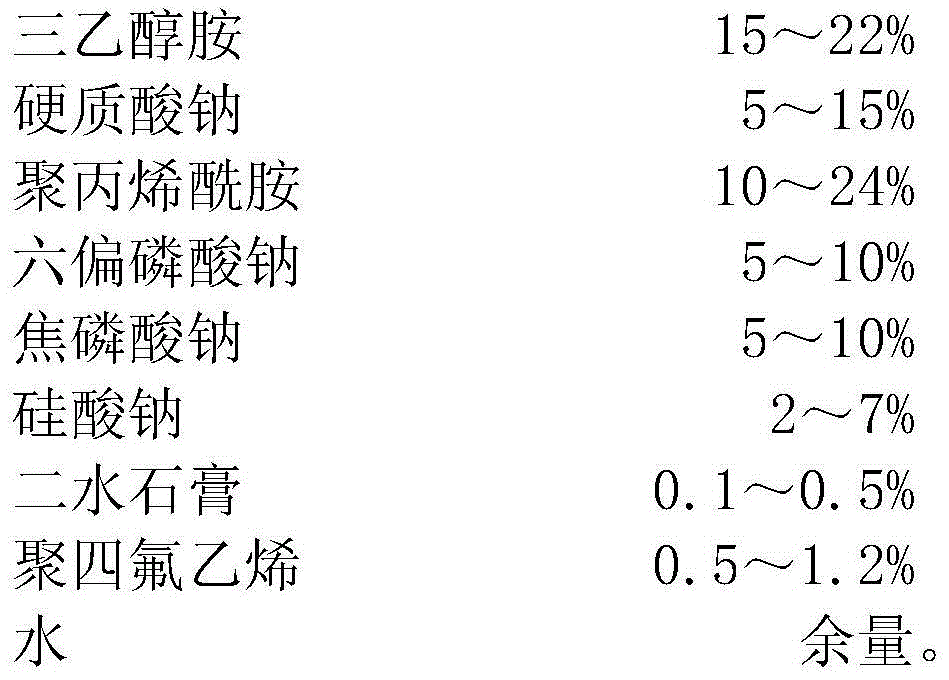

[0017] A kind of mineral powder grinding aid, is made of the raw material of following percentage by weight:

[0018]

[0019]

[0020] Heat water to 60°C, add dihydrate gypsum and polytetrafluoroethylene, stir evenly, cool down to 30°C, then add triethanolamine, sodium stearate, polyacrylamide, sodium hexametaphosphate in sequence, stir evenly to obtain Mineral powder grinding aid.

[0021] In this embodiment, when the ore powder is ground, the amount of the grinding aid added is 0.03% of the total amount of the ore powder to be ground.

Embodiment 2

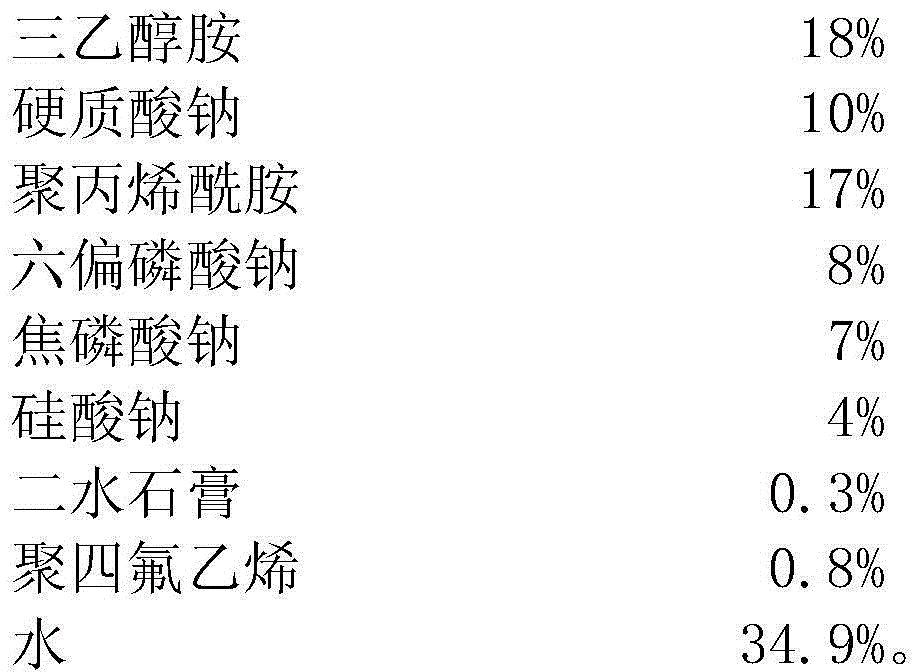

[0023] A kind of mineral powder grinding aid, is made of the raw material of following percentage by weight:

[0024]

[0025] Heat water to 60°C, add dihydrate gypsum and polytetrafluoroethylene, stir evenly, cool down to 30°C, then add triethanolamine, sodium stearate, polyacrylamide, sodium hexametaphosphate in sequence, stir evenly to obtain Mineral powder grinding aid.

[0026] In this embodiment, when the ore powder is ground, the amount of the grinding aid added is 0.04% of the total amount of the ore powder to be ground.

Embodiment 3

[0028] A kind of mineral powder grinding aid, is made of the raw material of following percentage by weight:

[0029]

[0030] Heat water to 60°C, add dihydrate gypsum and polytetrafluoroethylene, stir evenly, cool down to 30°C, then add triethanolamine, sodium stearate, polyacrylamide, sodium hexametaphosphate in sequence, stir evenly to obtain Mineral powder grinding aid.

[0031] In this embodiment, when the ore powder is ground, the amount of the grinding aid added is 0.05% of the total amount of the ore powder to be ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com