Compound cellulose indepth water shutoff modifying and flooding agent for oil production and preparation method thereof

A technology of compound cellulose and water-adjusting and flooding agent, which is applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve the problems of limiting the application of high temperature oil reservoirs, poor thermal stability and salt resistance, poor thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

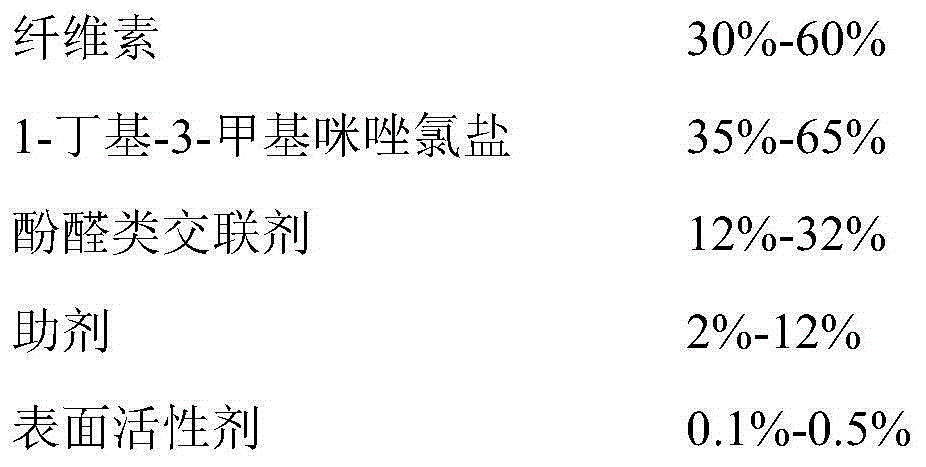

[0014] Embodiment 1: The composition of the composite cellulose deep water plugging and flooding regulating agent for oil recovery is calculated by mass percentage, and the formula is:

[0015]

[0016] Dissolve the cellulose with 1-butyl-3-methylimidazolium chloride salt, weigh the cellulose and add it to 1-butyl-3-methylimidazolium chloride salt, and react under stirring conditions at 100°C for 2 hours, Finally a 10 wt% clear solution was obtained. Then add a phenolic cross-linking agent and a surfactant, and add additives to adjust the pH to 6-7 under the condition of continuous stirring, and react for 3 hours to obtain the product.

[0017] The rotational speed of the stirring condition is 800r / min.

Embodiment 2

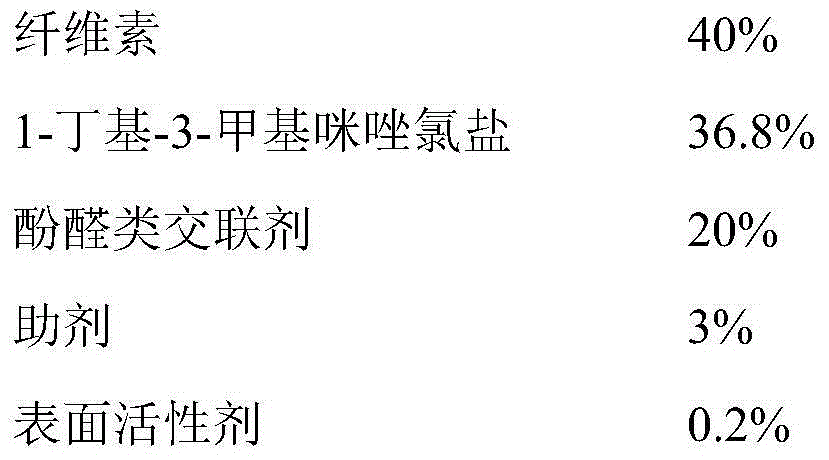

[0018] Embodiment 2: The composition of the composite cellulose deep water plugging and flooding agent for oil recovery is calculated by mass percentage, and the formula is:

[0019]

[0020]

[0021] Dissolve the cellulose with 1-butyl-3-methylimidazolium chloride salt, weigh the cellulose and add it to 1-butyl-3-methylimidazolium chloride salt, and react under stirring conditions at 100°C for 2 hours, Finally a 10 wt% clear solution was obtained. Then add a phenolic cross-linking agent and a surfactant, and add additives to adjust the pH to 7-9 under the condition of continuous stirring, and react for 2 hours to obtain the product.

[0022] The rotational speed of the stirring condition is 700r / min.

[0023] Compared with the first embodiment, the second embodiment has better high temperature resistance.

Embodiment 3

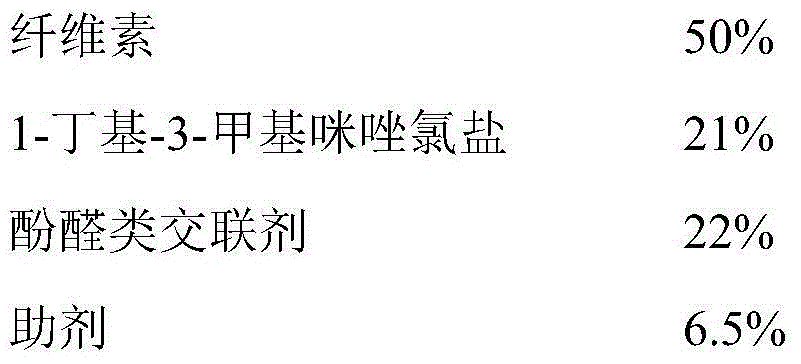

[0024] Embodiment three: The composition of the composite cellulose deep water plugging and flooding regulating agent for oil recovery is calculated by mass percentage, and the formula is:

[0025]

[0026] Dissolve the cellulose with 1-butyl-3-methylimidazolium chloride salt, weigh the cellulose and add it to 1-butyl-3-methylimidazolium chloride salt, and react under stirring conditions at 100°C for 2 hours, Finally a 10% by weight clear solution was obtained. Then add phenolic cross-linking agent and surfactant, under the condition of continuous stirring, add auxiliary agent to adjust pH to 11-12, react for 4 hours to obtain the product.

[0027] The rotational speed of the stirring condition is 1000r / min.

[0028] Compared with the second embodiment, the third embodiment has a longer crosslinking time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com