Method for reducing ethylene unit quenching oil viscosity and improving solvent recovery rate

A technology of ethylene plant and solvent recovery tower, which is applied in the petroleum industry, processing hydrocarbon oil, and only multi-stage serial refining process treatment, etc. It can solve problems such as unreasonable design, high load of quenching oil tower, and viscosity reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

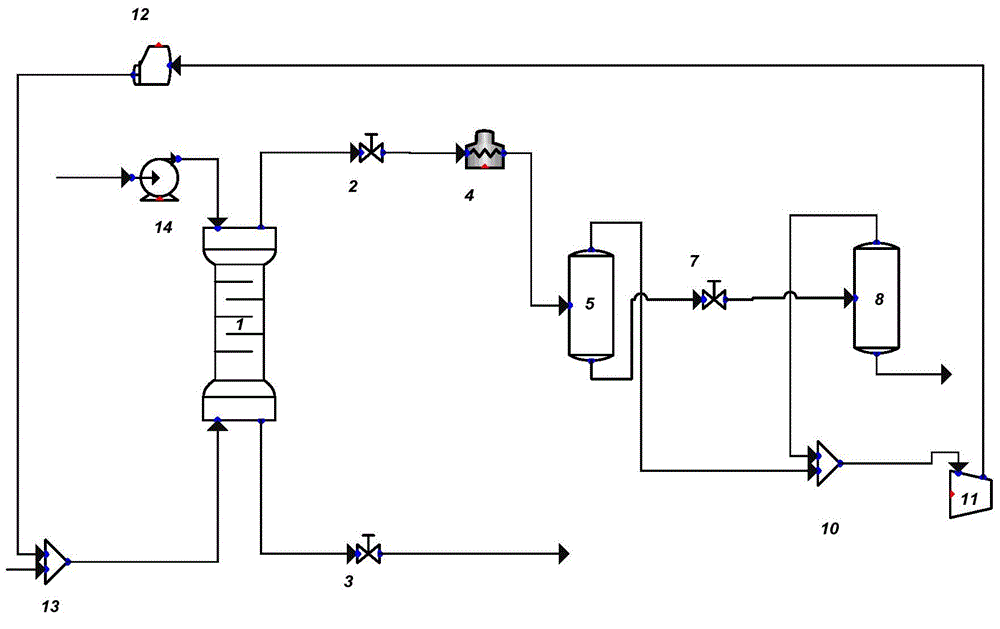

Image

Examples

Embodiment 1

[0036] Use propane as solvent for solvent extraction and viscosity reduction of quench oil. A stream of quench oil is drawn from the ethylene plant with a flow rate of 10t / h, and the obtained heavy quench oil is adjusted to a temperature of 30°C and a pressure of 5MPa. The solvent feed temperature is 30°C, the pressure is 5MPa, the flow rate is 5t / h, and the weight ratio of solvent to quench oil is 0.5. The quench oil and the solvent with a weight of 0.05 enter from the upper part of the extraction tower, and the rest of the solvent enters from the lower part of the extraction tower. The temperature of the extraction column is 30°C and the pressure is 5MPa. The extraction oil is separated from the top of the extraction tower, and the residual bitumen is separated from the bottom of the tower. After depressurizing the asphalt phase to 0.5MPa and removing the solvent, it is produced as fuel oil.

[0037] The pressure of the extracted oil flowing out of the top of the extraction ...

Embodiment 2

[0040] Use propane as solvent for solvent extraction and viscosity reduction of quench oil. A stream of quench oil is drawn from the ethylene plant with a flow rate of 10t / h, and the obtained heavy quench oil is adjusted to a temperature of 30°C and a pressure of 5MPa. The solvent feed temperature is 70°C, the pressure is 5MPa, the flow rate is 200t / h, and the weight ratio of solvent to quench oil is 20. The quench oil and the solvent with a weight of 0.05 enter from the upper part of the extraction tower, and the rest of the solvent enters from the lower part of the extraction tower. The temperature of the extraction column is 70°C and the pressure is 5MPa. The extraction oil is separated from the top of the extraction tower, and the residual bitumen is separated from the bottom of the tower. After depressurizing the asphalt phase to 0.5MPa and removing the solvent, it is produced as fuel oil.

[0041] The pressure of the extracted oil flowing out of the top of the extraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com