Gradient illumination photobioreactor and application thereof

A technology of photobioreactor and reactor, which is applied in photobioreactor, specific-purpose bioreactor/fermenter, combination of bioreactor/fermenter, etc. Reduce the utilization rate of light energy and other problems to achieve the effect of improving conversion utilization rate and cell yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

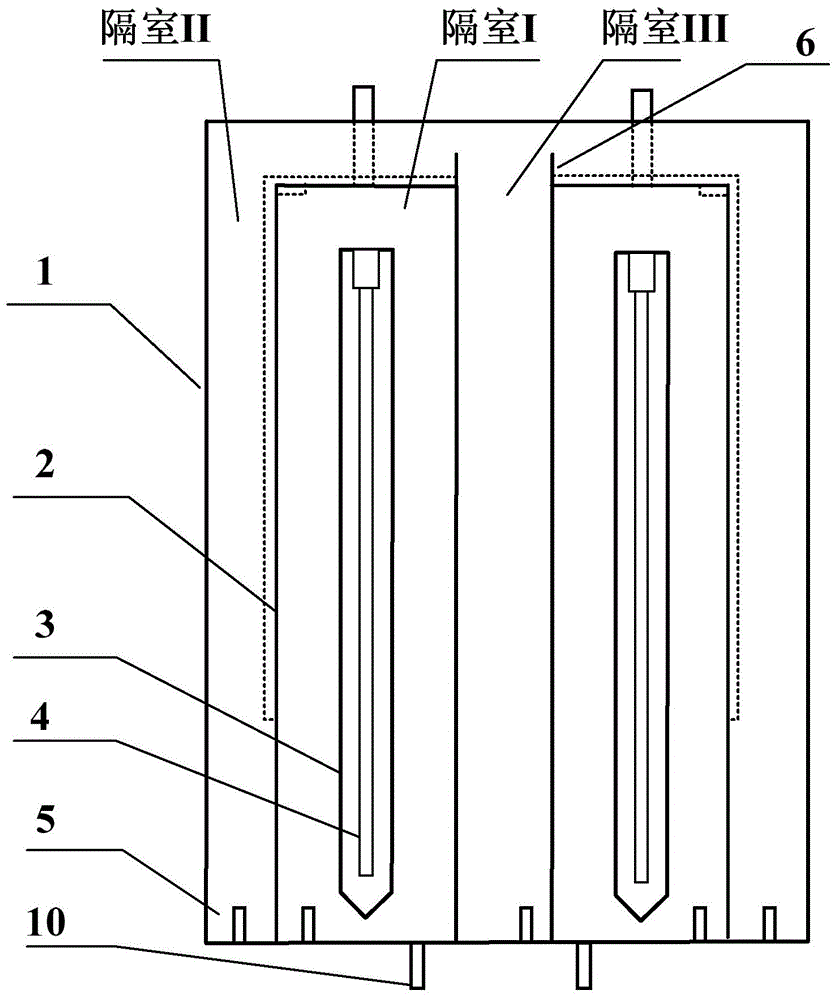

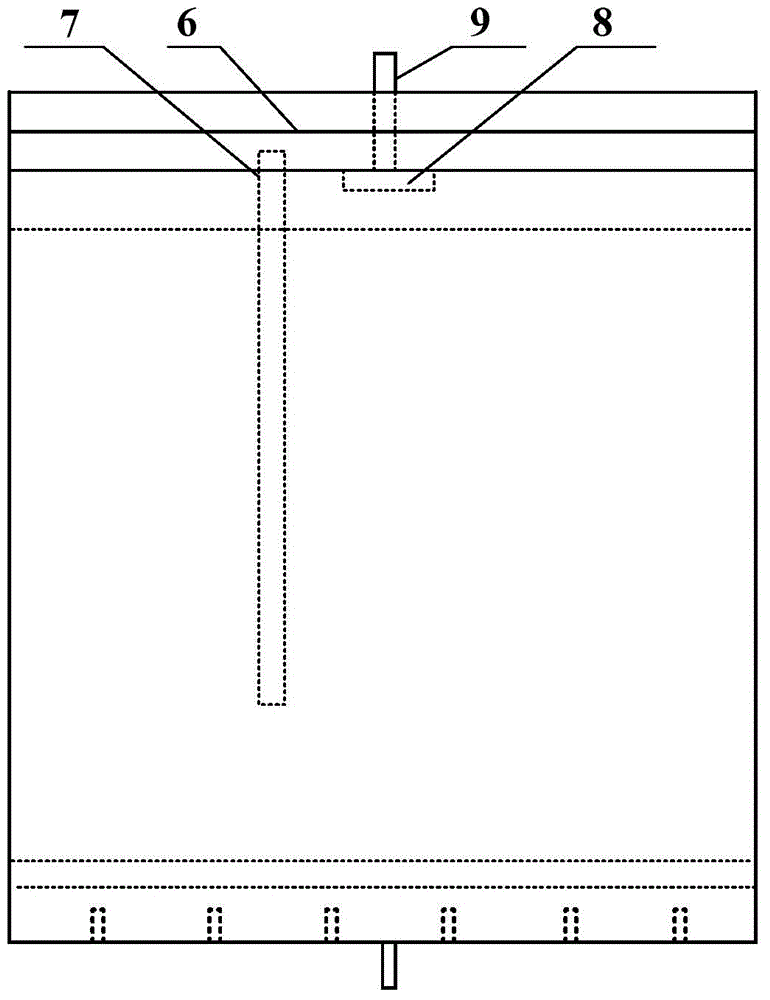

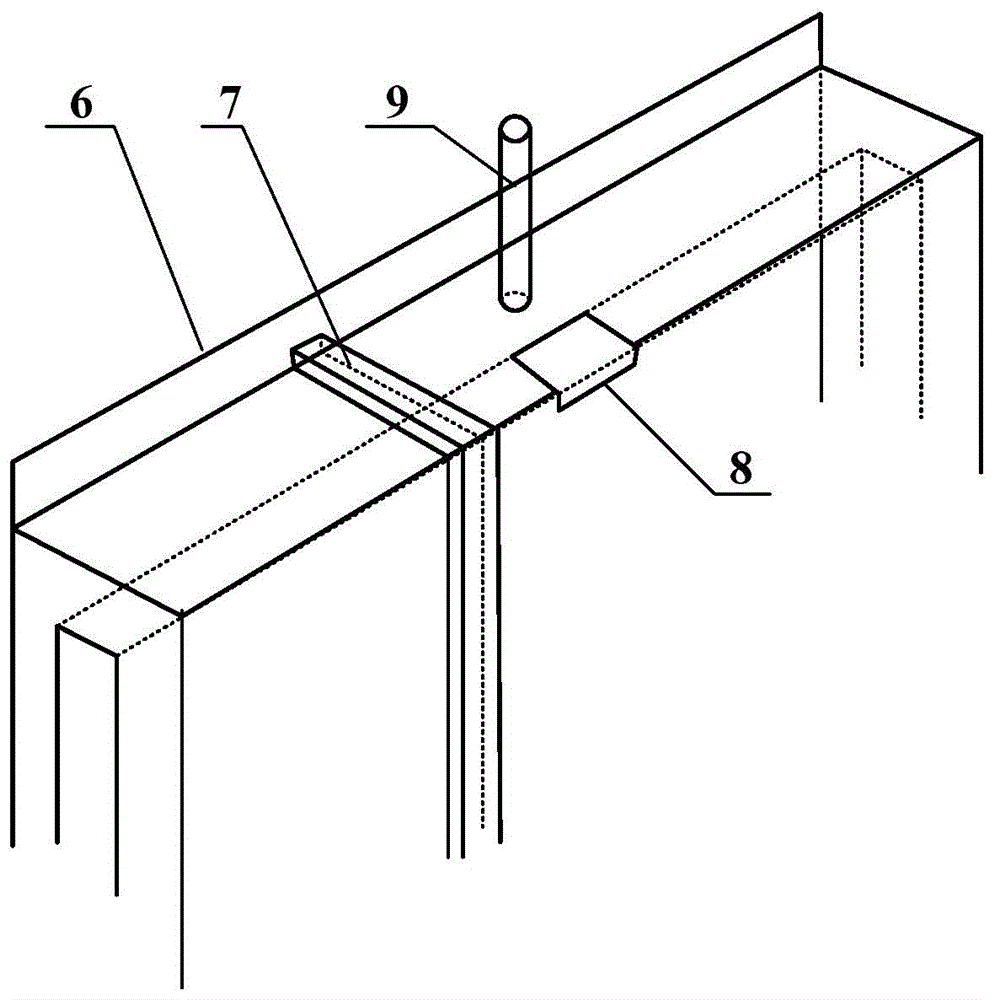

[0045] This embodiment shows the distribution of light quantum flux in the photoreactor of the present invention. The structural parameters of the reactor are as follows: the total height of the reactor is 70 cm, and the total length is 60 cm. The width w of one side of the compartment I is 10 cm, the height is 55 cm, the width of the light source chamber is 5 cm, the upper end of the light source chamber is 10 cm from the top of the compartment I, and the lower end of the light source chamber is 3 cm from the bottom of the compartment I. The width of compartment II is 10 cm, and the width of compartment III is 18 cm. The volume of liquid in the three compartments is: compartment I (two total) is 124L, compartment II (two total) is 58L, and compartment III is 59L. The overflow weir at the top of compartment I is 5cm high, the outlet of the overflow pipe is 20cm from the bottom of compartment II, and the overflow opening is 3cm wide. The gas outlet and the discharge port are a...

Embodiment 2

[0047] This embodiment shows the distribution of light quantum flux in the photoreactor of the present invention. The structural parameters of the reactor are as follows: the total height of the reactor is 110 cm, and the total length is 80 cm. The width w of one side of the compartment I is 12 cm, the height is 95 cm, the width of the light source chamber is 6 cm, the upper end of the light source chamber is 15 cm from the top of the compartment I, and the lower end of the light source chamber is 5 cm from the bottom of the compartment I. The width of compartment II is 10 cm, and the width of compartment III is 18 cm. The volume of liquid in the three compartments is: compartment I (two total) is 336L, compartment II (two total) is 146L, and compartment III is 146L. The height of the overflow weir is 10cm, the outlet of the overflow pipe is 35cm from the bottom of the compartment II, and the width of the overflow is 5cm. The gas outlet and the discharge port are arranged in ...

Embodiment 3

[0049] This example is the batch cultivation of marine chlorella sp using the photoreactor of the present invention. The reactor is the same as in Example 1. In the room, a fluorescent lamp is used to simulate sunlight, and the light parameters are maintained as in Example 1, and the light-dark cycle is 16h:8h. The medium is F / 2 modified medium, the inoculum concentration is 1.2×10 6 cell / mL. After inoculation, the algae were cultured in Compartment III for 48 hours and then transferred to Compartment II to continue the cultivation. At the same time, the new culture medium was refilled in Compartment III and kept pressing 1.2×10 6 Cell / mL inoculation; after 48 hours of culture in compartment II, transfer to compartment I to continue culturing, and at the same time transfer the next batch of algae liquid from compartment III to compartment II. Microalgae are cultured in compartment I for 112 hours and then collected Close. The ventilation volume in compartment III, compartment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com