Tin-plating production line

A production line and tin-plating technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problem that the tin skin is easily rubbed off or ground into a flower shape, the tin liquid does not completely wrap the copper wire, Affect the initial tinning effect and other issues, to achieve the effect of improving the tinning effect, increasing the tinning time, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

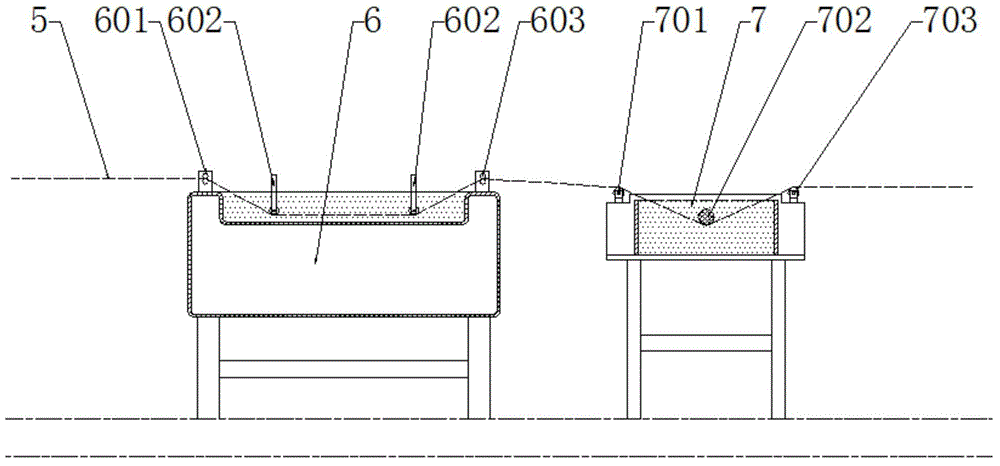

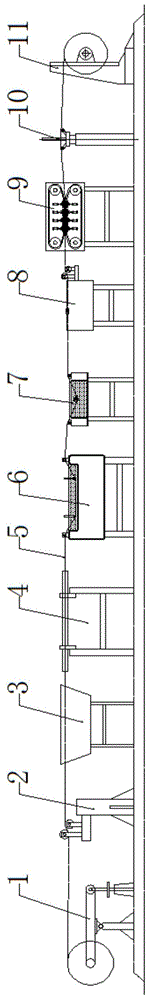

[0015] Such as figure 1 As shown, a tinning production line is characterized in that it includes a tinning device 6, a tin tank guide wheel guide 601, a tin tank pressure wheel set 602, a tin tank asbestos guide 603, a tin plating cooling tank 7, and a cooling tank asbestos guide 701 , cooling tank pinch wheel 702, cooling tank guide wheel guide 703, said tinning device 6 is equipped with tin tank guide wheel guide 601 at the wire-entry end, said tinning device 6 tin tanks are equipped with tin tank pressing wheel group 602 , the tinning device 6 is equipped with a tin tank asbestos guide 603 at the outlet end, and a tinning cooling tank 7 is arranged behind the tinning device 6, and a cooling tank asbestos guide is installed at the inlet end of the tinning cooling tank 7 701, the tin-plated cooling tank 7 is equipped with a cooling tank pressure wheel 702 in the cooling tank, and the tin-plated cooling tank 7 is equipped with a cooling tank guide wheel guide 703 at the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com