Oil removal powder for cleaning heavy oil stains and preparation method of oil removal powder

A technology of oil stains and oil powder, which is applied in the field of degreasing powder for cleaning heavy oil stains and its preparation, can solve problems affecting human drinking water safety, etc., and achieve the effects of enhanced degreasing effect, less impact on human health, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

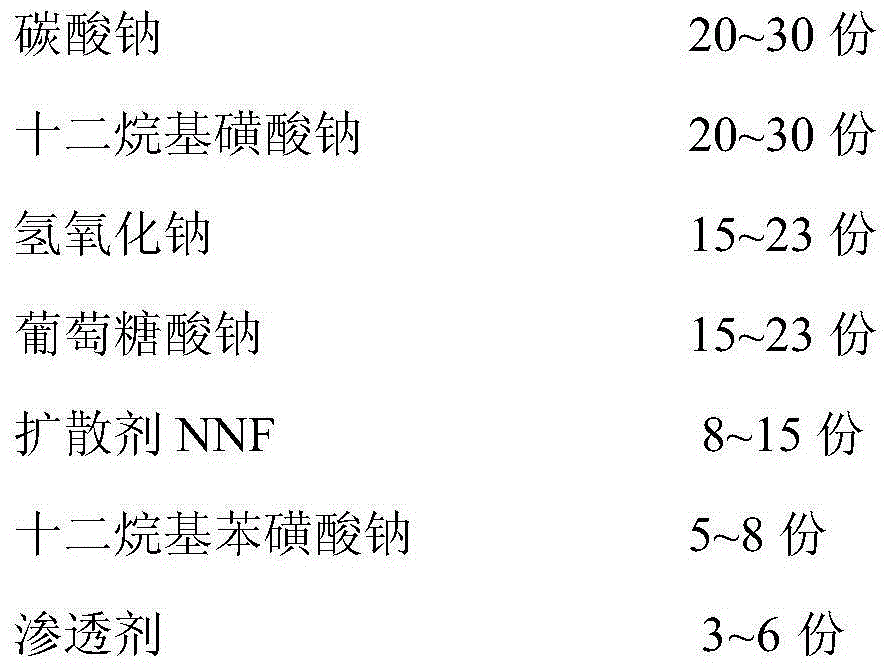

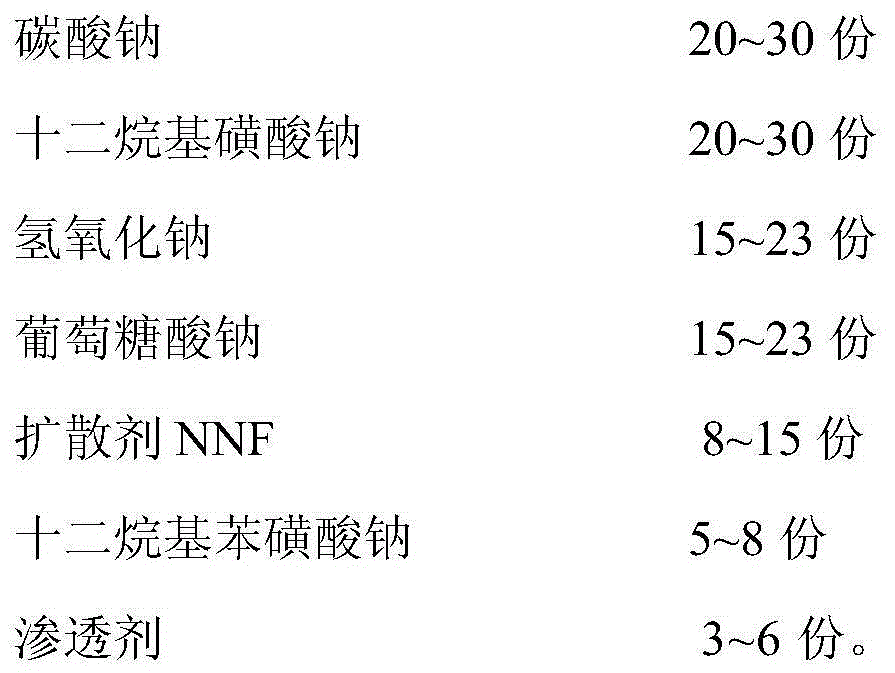

Embodiment 1

[0019] Take the raw materials according to the weight parts of each component specified in Table 1. Stir the sodium hydroxide, sodium dodecyl sulfonate, and sodium carbonate for 30 minutes, and get A powder after being uniform, and then add sodium gluconate to A powder. Stir for 20 minutes to obtain powder B after uniformity, then add sodium dodecylbenzene sulfonate to powder B, stir for 20 minutes, obtain powder C after uniformity, then add penetrant JFC to powder C, stir for 20 minutes, and obtain D powder, finally add D powder into the diffuser NNF, stir for 30 minutes, and get degreasing powder after uniformity.

Embodiment 2

[0021] Take the raw materials according to the weight parts of each component specified in Table 1, stir the sodium hydroxide, sodium dodecyl sulfonate, and sodium carbonate to obtain powder A, then add sodium gluconate to powder A and stir to obtain B Powder, add sodium dodecylbenzene sulfonate into B powder, stir evenly to obtain C powder, then add penetrant JFC to C powder, stir evenly to obtain D powder, finally add diffusing agent NNF to D powder, stir evenly to obtain Oil powder.

Embodiment 3

[0023] Take the raw materials according to the parts by weight of each component specified in Table 1, stir the sodium hydroxide, sodium dodecyl sulfonate, and sodium carbonate for 20 minutes to obtain powder A after being uniform, and then add sodium gluconate to powder A. Stir for 15 minutes to get B powder evenly, then add sodium dodecylbenzene sulfonate to B powder, stir for 15 minutes, get C powder after uniformity, then add penetrant JFC to C powder, stir for 15 minutes, and get even D powder, finally add the diffuser NNF to D powder, stir for 20 minutes, and get degreasing powder after uniformity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com