Water treatment control valve

A salt water control valve, control valve technology, applied in the direction of sliding valve, multi-port valve, valve device, etc., can solve the problem of small flow rate of control valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1: downstream regeneration scheme

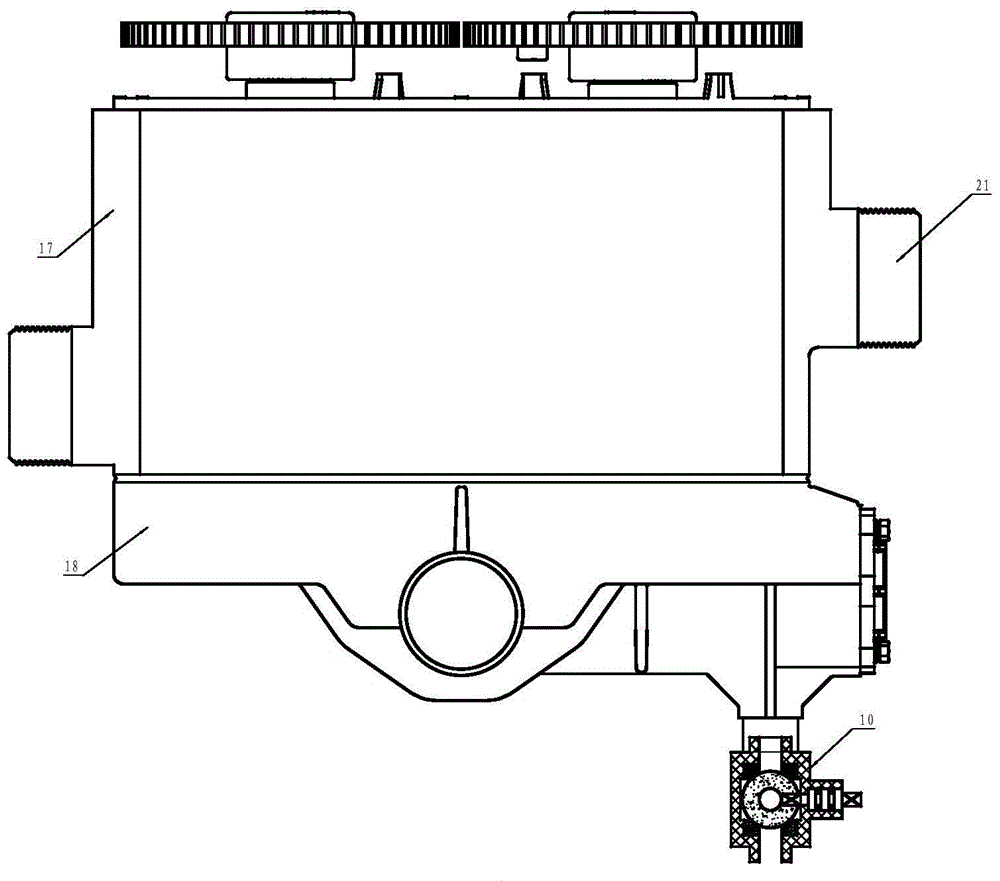

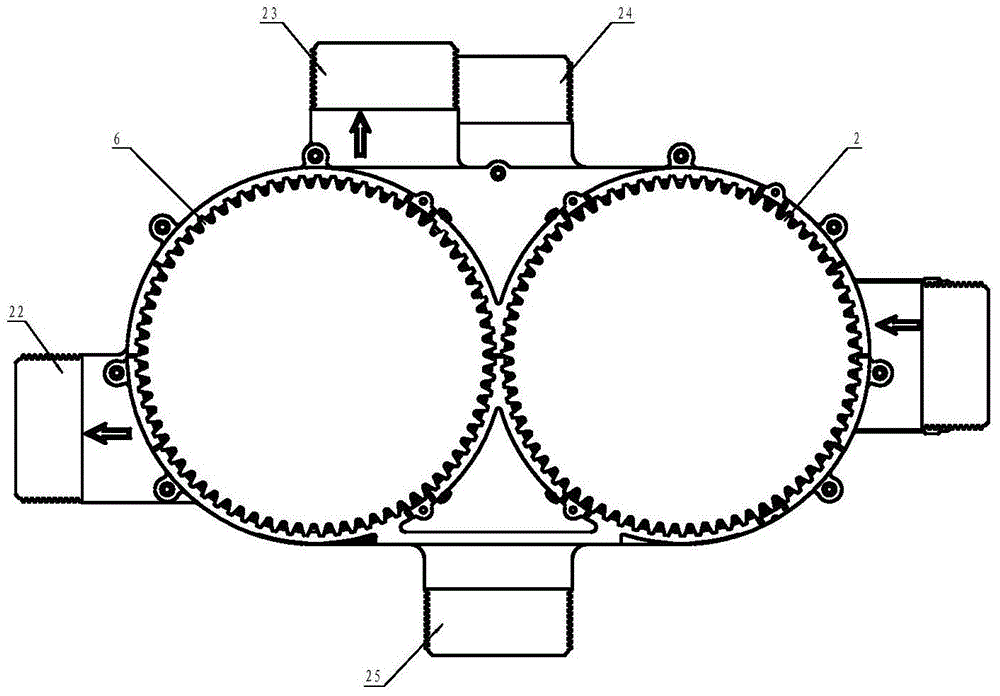

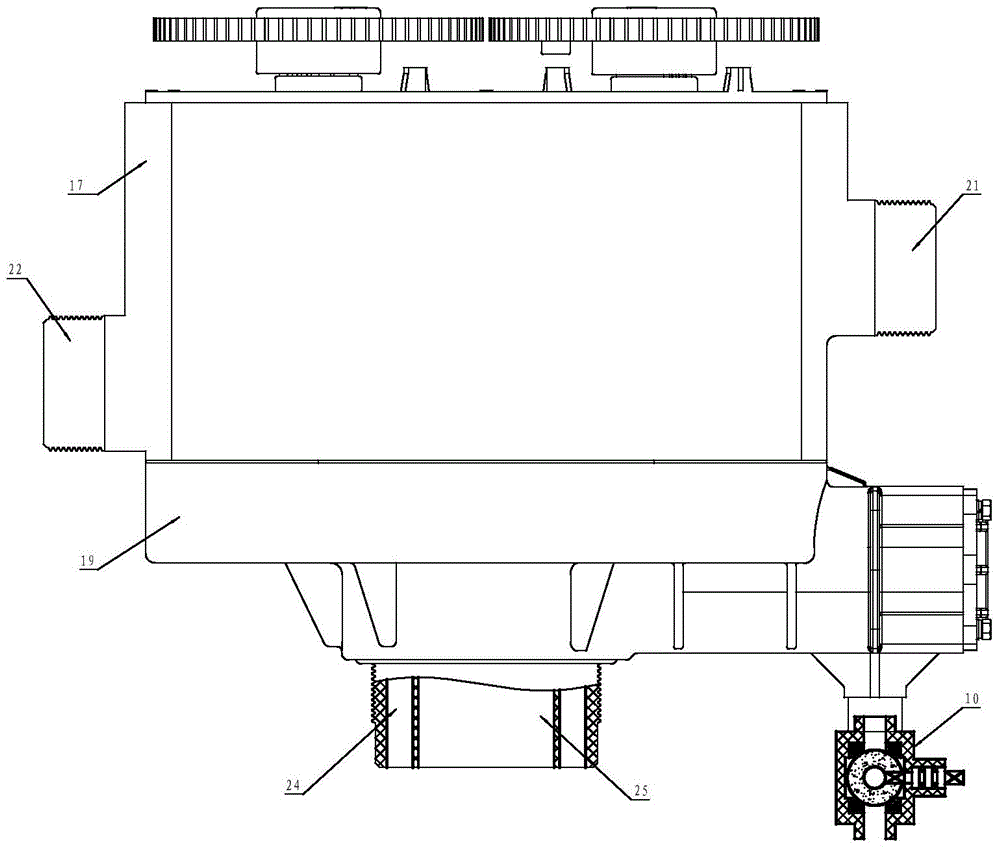

[0081] Such as Figure 1-8 As shown, in this embodiment, using Figure 5 and Figure 6 The fixed valve plate and the movable valve plate of the water inlet valve core shown are adopted Figure 7 and Figure 8 The water outlet spool shown is the fixed valve plate and the movable valve plate. In the control valve in Embodiment 1, the valve body 1 is formed by welding or screwing the upper valve body 17 and the lower valve body 18 , and the whole body consisting of the upper valve body and the lower valve body will be introduced below. The valve body 1 is provided with a water inlet 21, a water outlet 22, a drain port 23, an upper filter element interface 24, a filter element lower interface 25, and a branch flow channel 26. The branch flow channel 26 is provided with a jet inlet 27, The ejector outlet 28 normally connected to the filter element upper interface 24, the brine inlet 29, and the brine control valve 10 connected...

Embodiment 2

[0089]Example 2: Countercurrent regeneration and soft water supply scheme

[0090] Such as Figure 22 As shown, in this embodiment, using Figure 5 and Figure 6 The fixed valve plate 5 and the moving valve plate 4 of the water inlet valve core shown are adopted Figure 7 and Figure 8 Shown water outlet valve core fixed valve plate 9 and movable valve plate 8. The valve body 1 is provided with a water inlet 21, a water outlet 22, a drain port 23, an upper filter element interface 24, a filter element lower interface 25, and a branch flow channel 26. The branch flow channel 26 is provided with a jet inlet 27, The ejector outlet 28 normally connected with the filter element lower interface 25, the brine inlet 29, and the brine control valve 10 connected with the brine inlet 29. A water inlet valve core and a water outlet valve core are installed in the valve body 1 . The fixed valve plate 5 of the water inlet valve core is provided with three through holes, the first thro...

Embodiment 3

[0095] Embodiment 3: Floating bed, soft water supply scheme

[0096] The softened water of the floating bed adopts the way of countercurrent operation, and the resin layer filled in the tank of the floating bed is high, so it can handle water with high hardness. Due to the large amount of resin filling, the floating bed has no backwash function, and the regeneration of salt absorption adopts the method of mixed water flow from top to bottom.

[0097] Such as Figure 27 As shown, in this embodiment, using Figure 26 and Figure 6 The fixed valve plate 5 and the moving valve plate 4 of the water inlet valve core shown are adopted Figure 7 and Figure 8 Shown water outlet valve core fixed valve plate 9 and movable valve plate 8. The valve body 1 is provided with a water inlet 21, a water outlet 22, a drain port 23, an upper filter element interface 24, a filter element lower interface 25, and a branch flow channel 26. The branch flow channel 26 is provided with a jet inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com