Method for recovering carbon sulfide and hydrogen in separation mode

A carbon disulfide, separation and recovery technology, used in nitrogen purification/separation, liquefaction, chemical industry, etc., to optimize the factory environment, reduce production costs, and eliminate potential safety hazards.

Inactive Publication Date: 2015-03-25

江西恒兴源化工有限公司

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

There are also a small number of enterprises using cryogenic technology, that is, adjusting the working temperature of the condensed gas to below -30°C, so that CS2 can be recovered to more than 90%, but this method consumes a lot of energy and equipment configuration The more important thing is that the water vapor in the mixed gas is difficult to achieve 100% separation and removal. After a certain period of time, the medium channel in the condenser will be blocked by the slowly accumulated trace water vapor, resulting in Condenser cannot continue to work normally

At the same time, in these methods, N2 is directly discharged into the atmosphere, and has not been recycled.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Login to View More

Abstract

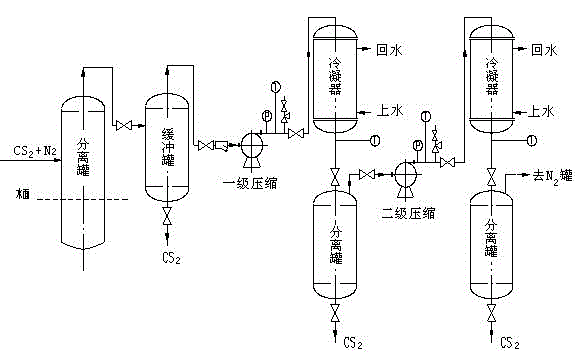

The invention discloses a method for recovering carbon sulfide and hydrogen in a separation mode. According to the method, mixed gas of the hydrogen and the carbon sulfide discharged from production tail gas passes through a gas-liquid separator and then enters a buffering tank and a two-stage compression system; after compression cooling, the carbon sulfide is liquefied into carbon sulfide liquid, and the hydrogen is delivered into a hydrogen storage tank and used for partial production systems. The technology that multi-stage compression is performed on the mixed gas of the carbons sulfide (CS2) and the hydrogen (N2) so that the carbon sulfide and the hydrogen can be recovered in the separation mode is adopted; the mixed gas of the CS2 and the N2 can be separated and then repeatedly used by 100%, in this way, the factory environment is optimized, the potential safety hazard that CS2 is discharged into the atmosphere and is flammable and combustible are eliminated, and meanwhile the multiple effects that energy is saved, consumption is lowered, the production cost is lowered, and economic benefits are increased are achieved.

Description

[0001] technical field [0002] The invention relates to a method for separating and recovering carbon disulfide and nitrogen from a mixed gas of carbon disulfide and nitrogen, belonging to the technical field of insoluble sulfur production technology. Background technique [0003] Sulfur (including insoluble sulfur and soluble sulfur) is a flammable substance, so it must be anaerobic when heating sulfur during the production of insoluble sulfur, so the air in the container must be drained first, and at the same time filled with nitrogen for protection. However, during the sulfur quenching process, the high-temperature insoluble sulfur and nitrogen are released together to exchange heat with the quenching medium carbon disulfide, so that the metastable high-temperature molten insoluble sulfur becomes solid stable insoluble sulfur, and the quenching medium carbon disulfide absorbs a large amount of carbon disulfide from high temperature. The heat released by melting insol...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F25J3/08C01B31/26C01B21/04

CPCY02P20/10

Inventor 张友辉谭建中

Owner 江西恒兴源化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com