Detection method for volatile flavor substance of edible vegetable oil

A technology of edible vegetable oil and flavor substances, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of few research reports on volatile flavor components, and achieve the effect of simple sample pretreatment and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

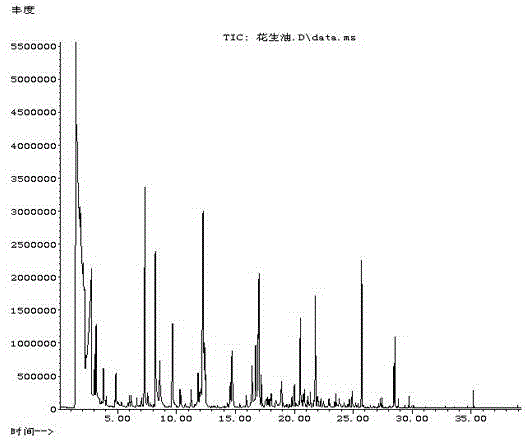

[0024] Embodiment 1 (peanut oil):

[0025] 1. Sample processing

[0026] Weigh 5.0 g of the sample into a 20 mL headspace bottle, put it into a constant temperature magnetic stirrer, stir at a speed of 2000 r / min, and preheat it in a water bath at 60°C for 20 min at a constant temperature. The aged 50 / 30 μm DVB / CAR / The PDMS solid-phase microextraction head was inserted into the headspace bottle, and after 45 minutes of adsorption, the extraction head was taken out and inserted into the gas chromatography inlet, and analyzed at 250 °C for 5 minutes to carry out the extraction and enrichment of volatile flavor substances (GC-MS analysis).

[0027] 2. Inject gas chromatography-mass spectrometry (HS-SPME) separation and detection

[0028] Gas chromatography using Agilent 6890N:

[0029] ①The analytical column is J&W DB-5MS UI elastic quartz capillary column (30m*0.25mm*0.25um);

[0030] ② Carrier gas: helium, the flow rate is 1.0mL / min;

[0031] ③Sampling method: splitless i...

Embodiment 2

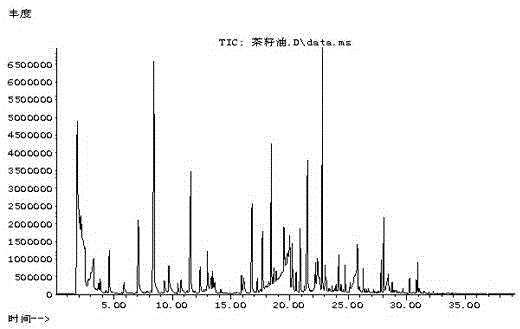

[0045] Embodiment 2 (tea seed oil):

[0046] 1. Sample processing

[0047] Weigh 5.0 g of the sample into a 20 mL headspace bottle, put it into a constant temperature magnetic stirrer, stir at a speed of 2000 r / min, and preheat it in a water bath at 60 °C for 15 min, and put the aged 50 / 30 μm DVB / CAR / The PDMS solid-phase microextraction head was inserted into the headspace bottle, and after 40 min of adsorption, the extraction head was taken out and inserted into the gas chromatography inlet, and analyzed at 250 °C for 5 min for GC-MS analysis.

[0048] 2. Inject gas chromatography-mass spectrometry (HS-SPME) separation and detection

[0049] Gas chromatography using Agilent 6890N:

[0050] ①The analytical column is J&W DB-5MS UI elastic quartz capillary column (30m*0.25mm*0.25um);

[0051] ② Carrier gas: helium, the flow rate is 1.0mL / min;

[0052] ③Sampling method: splitless injection;

[0053] ④ The temperature of the injection port is 250°C, and the temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com