Automatic phase mask plate switching device

A phase mask and automatic switching technology, which is applied in the field of fiber gratings, can solve the problems of difficulty in controlling the relative position accurately, affecting the quality of writing grating, and slow writing speed of grating, so as to achieve good writing quality and repeatability, high switching accuracy, and high-level consistent distance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings, but the protection scope of the present invention should not be limited by this.

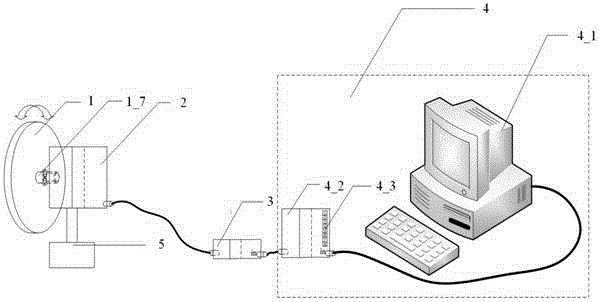

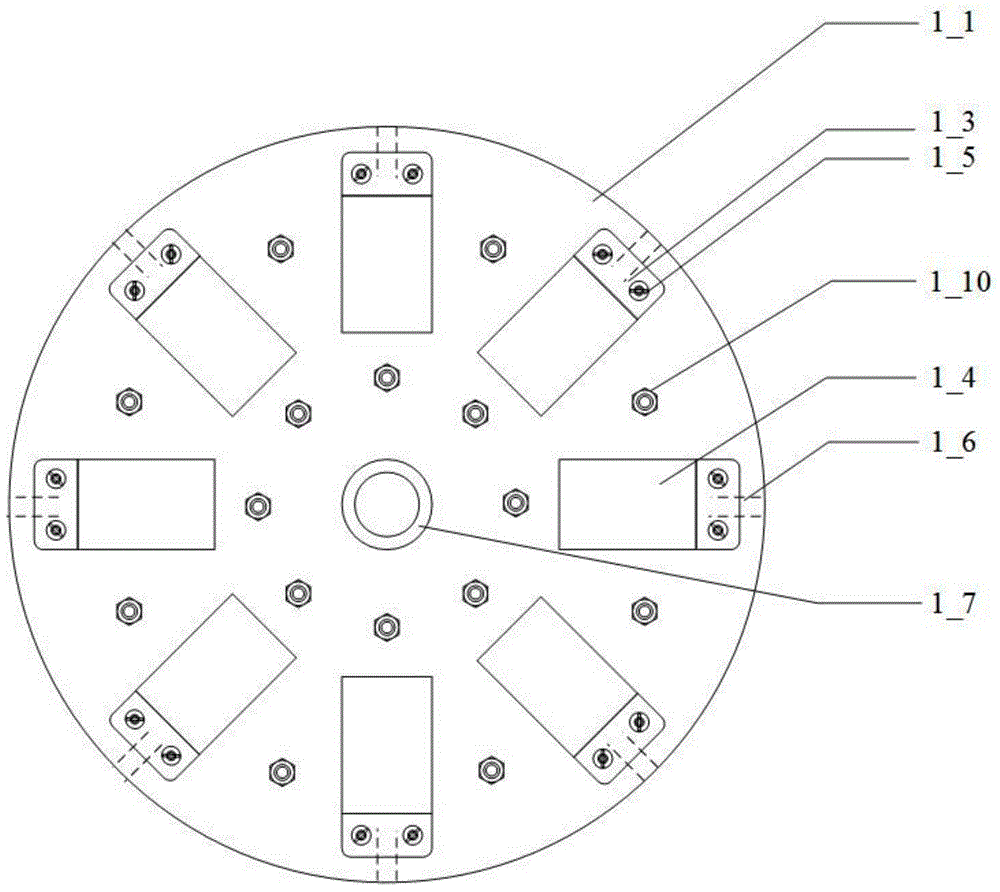

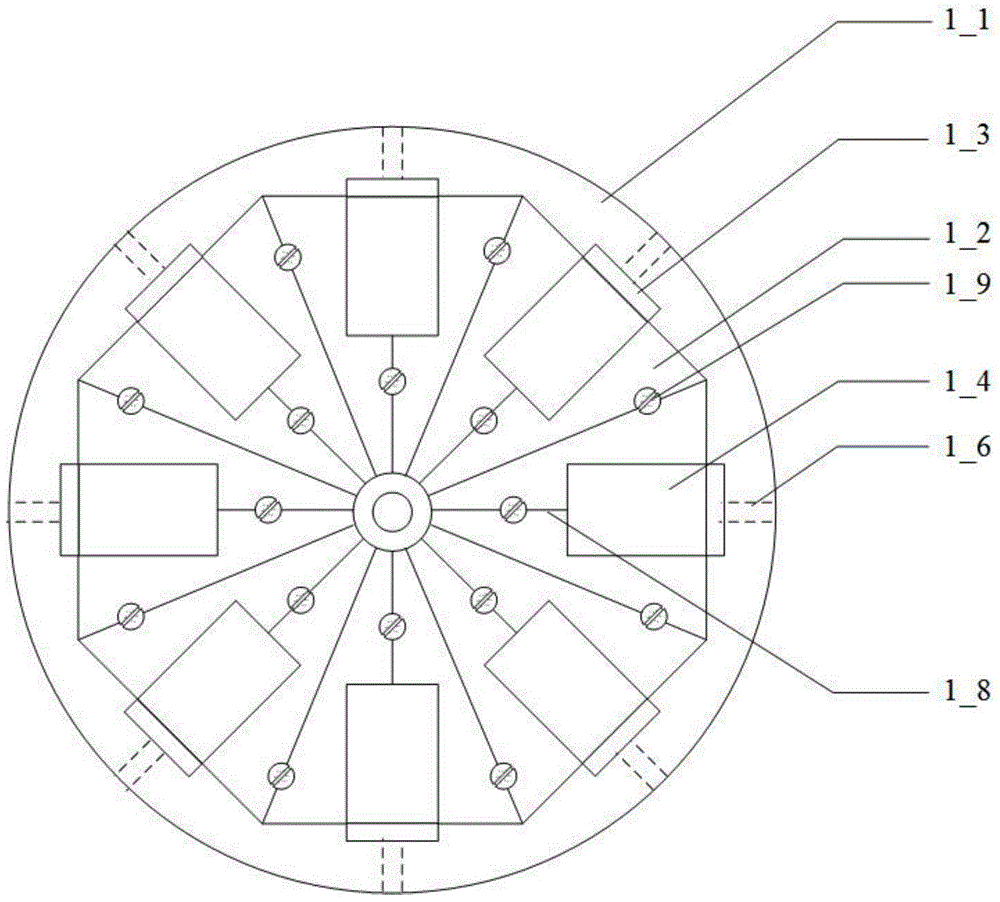

[0021] The phase mask automatic switching device of the present invention, such as figure 1 As shown, the structure includes a phase mask rotation switching fixture 1, a stepping motor 2, a driving circuit 3 and a control system 4, and the rotating shaft of the stepping motor 2 is fixed on the center sleeve of the phase mask rotation switching fixture 1 In 1_7, the described stepping motor 2 is fixed on the bracket 5, the described control system 4 is composed of the upper computer 4_1 and the lower computer 4_2, the upper computer 4_1 is connected with the described The input end of the stepping motor 2 is connected, and the phase mask rotates and switches the fixture 1 (see figure 2 , image 3 ) comprises a disc-shaped base 1_1, a positioning block 1_2 and a pressing piece 1_3, the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com