MoS2/Si p-n junction solar cell device and preparation method thereof

A solar cell and device technology, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of light absorption and electron transfer defects, complex preparation process, high rate of defective products, etc., achieve weak light-induced attenuation effect, repeatable High performance and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

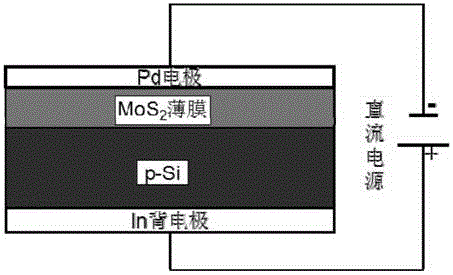

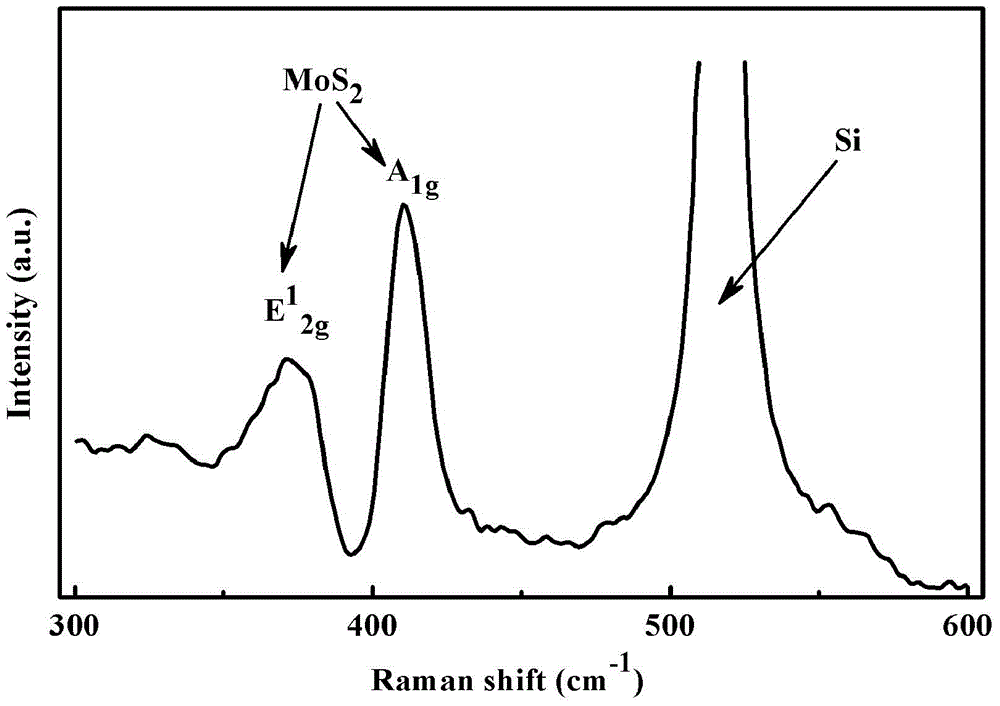

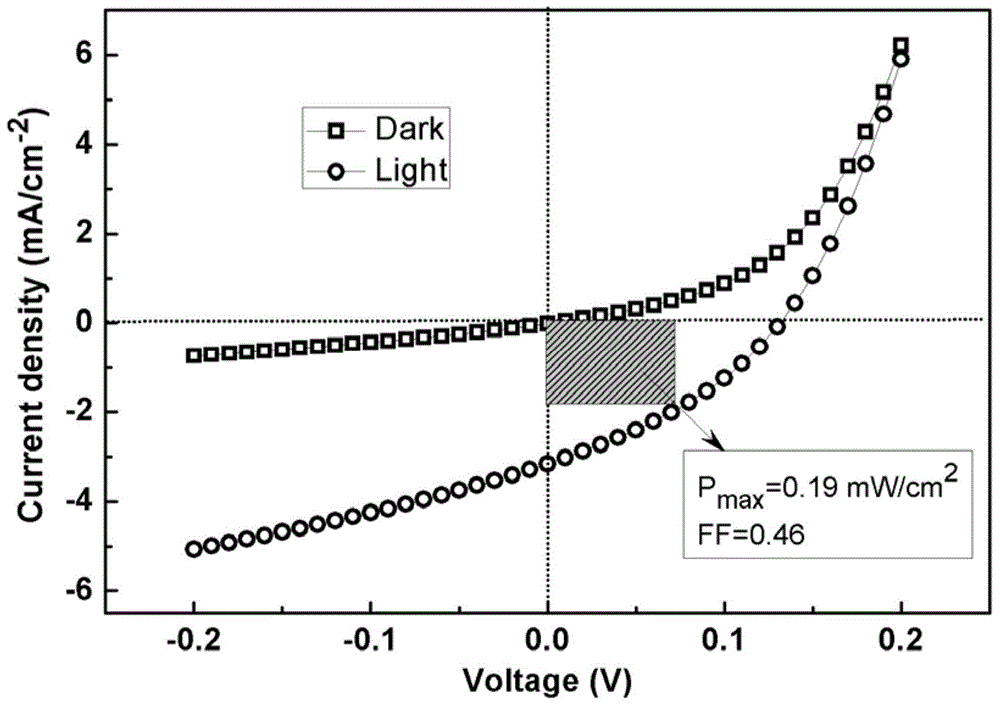

[0029] The present invention utilizes DC magnetron sputtering technology to deposit MoS on p-Si semiconductor substrate 2 Thin film layer, forming a p-n junction. When there is light, under the action of the built-in electric field, the photogenerated carriers diffuse and drift, and finally a stable photogenerated voltage is formed at both ends of the p-n junction, that is, the photovoltaic effect.

[0030] Next to MoS 2 / Si p-n junction solar cell device structure and preparation methods are described in detail.

[0031] A kind of MoS 2 / Si p-n junction solar cell devices, including MoS 2 Thin film layer, as MoS 2 The Si substrate of the thin film layer carrier, the metal Pd front electrode and the metal In back electrode. MoS 2 The thin film layer is set on the surface of Si substrate, MoS 2 The thickness of the film layer is 70-80nm, the Si substrate is a p-type Si single crystal substrate, and the resistivity is 1.2-1.8Ω·cm. Metal Pd front electrode set on MoS 2 On...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com