High-radiating LED circuit board

A LED circuit board, high heat dissipation technology, applied in the direction of printed circuits, printed circuits, printed circuit components, etc., can solve the problems of the insulation layer losing the insulation effect, the insulation effect of the insulation layer cannot be guaranteed, and the heat cannot be transferred laterally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

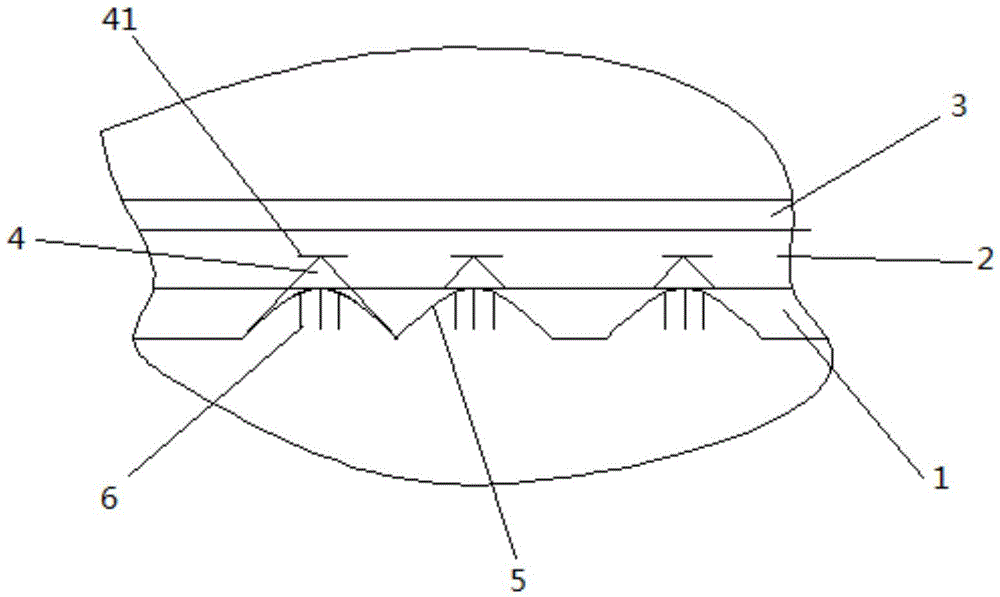

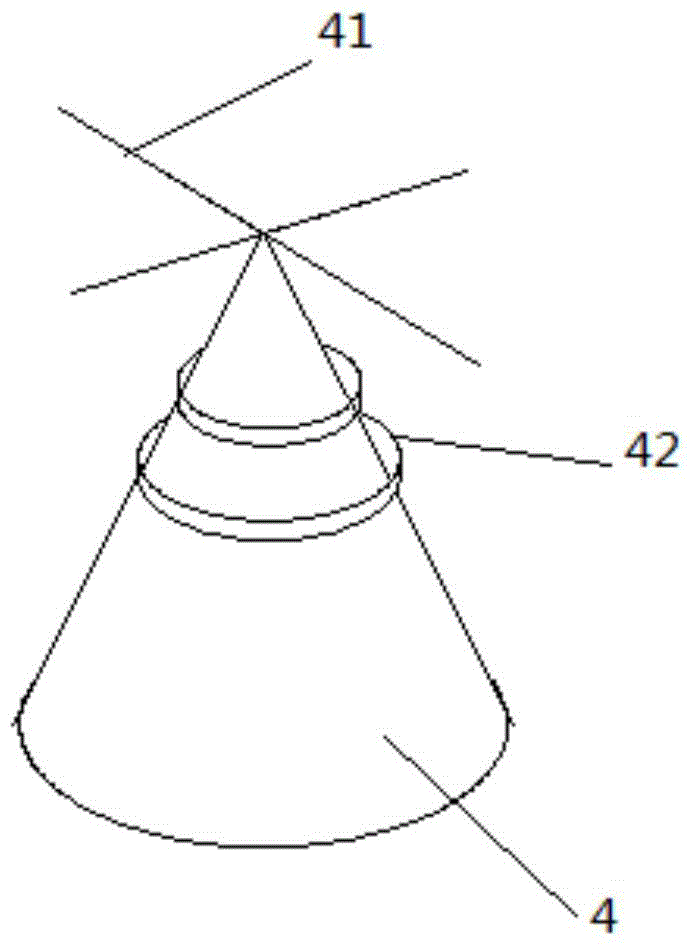

[0017] This embodiment provides a high heat dissipation LED circuit board, such as figure 1 and figure 2 , from bottom to top, a 0.8mm thick heat dissipation base layer 1, a 0.65mm thick insulating and heat conducting layer 2 and a circuit layer 3 are sequentially provided. The heat dissipation base layer is a metal plate, and a plurality of tapered bumps 4 are provided on its upper surface; Two intersecting heat transfer strips 41 are arranged on the top of the tapered bump.

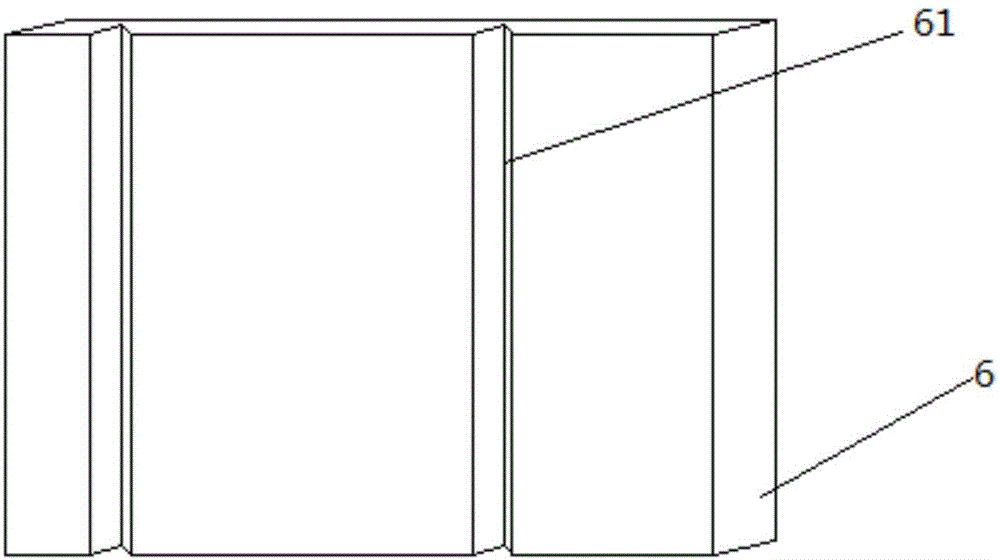

[0018] A concave curved surface 5 is provided on the lower surface of the heat dissipation base layer corresponding to the tapered bump; three cooling fins 6 are vertically provided on the concave curved surface; image 3 The surface of the heat dissipation fins is provided with a heat dissipation groove 61 perpendicular to the heat dissipation base layer; the cross section of the heat dissipation groove is triangular.

[0019] Two protruding annular rings 42 are provided on the surface of the tapere...

Embodiment 2

[0022] This embodiment provides a high heat dissipation LED circuit board, the structure of which is consistent with that of Embodiment 1. Particularly preferably, the heat dissipation base layer described in this embodiment is made of 96 parts by weight of aluminum, 3.2 parts of copper and 0.01 part of titanium dioxide, 0.005 parts of magnesium sulfate and 0.002 parts of nano-silver particles; the insulating and heat-conducting layer raw materials include 70 parts of polypropylene, 1 part of silicon dioxide particles, 4 parts of polycarbonate, 0.02 parts of flame retardant, 0.15 parts of lactic acid by weight Calcium and 1 part elemental sulfur.

Embodiment 3

[0024] This embodiment provides a high heat dissipation LED circuit board, the structure of which is consistent with that of Embodiment 1. Particularly preferably, the heat dissipation base layer described in this embodiment is made of 96 parts by weight of aluminum, 3.2 parts of copper and 0.01 part of titanium dioxide, 0.005 parts of magnesium sulfate and 0.002 parts of nano-silver particles; the insulating and heat-conducting layer raw materials include 60 parts of polypropylene, 5 parts of silicon dioxide particles, 3 parts of polycarbonate, 0.05 parts of flame retardants, and 0.01 parts of lactic acid by weight Calcium and 3 parts of elemental sulfur.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com