Method for treating waste gas containing hydrogen sulfide and carbon disulfide and corresponding device of method

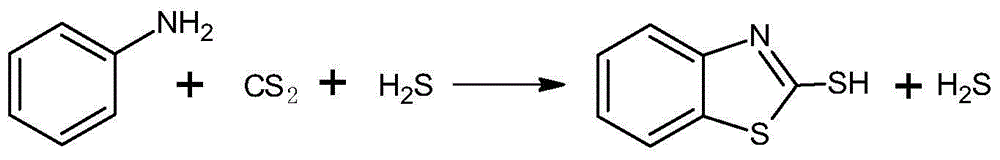

A technology of carbon disulfide and hydrogen sulfide, which is applied in the waste field containing hydrogen sulfide, carbon disulfide and sulfur-containing organic matter, and can solve the problem of insufficient utilization of tail gas substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

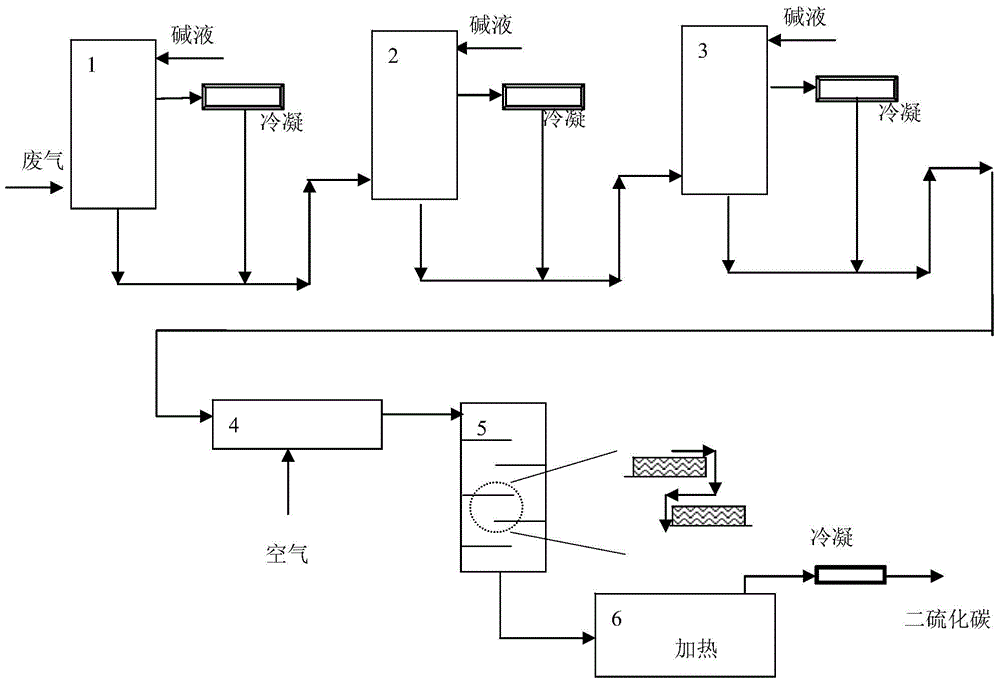

[0027] After the exhaust gas from a rubber factory is introduced into the 3-stage serial spray tower (7.9% NaOH solution), the effluent is added to the heating reaction kettle with a heating temperature of 107 degrees Celsius and a pressure of 0.185 MPa, heated until the precipitate is dissolved, and then introduced into the plate tower containing mercury In the middle, after flowing out, it is heated to 52 degrees Celsius to produce red cinnabar, and the carbon disulfide is evaporated, condensed, recycled and reused. After the cinnabar is filtered and cleaned, it fully meets the requirements as a pigment. There is no waste gas emission and waste liquid flow out during the whole process, which can Compared with the Claus method, the consumption is reduced by about 37%, and cinnabar can be sold as pigment and Chinese medicinal material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com