Method for reducing heat release during hydration of magnesium oxychloride cement

A magnesium oxychloride cement and heat release technology, which is applied in the field of building materials and can solve the problems of restricting large-scale application and large heat release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

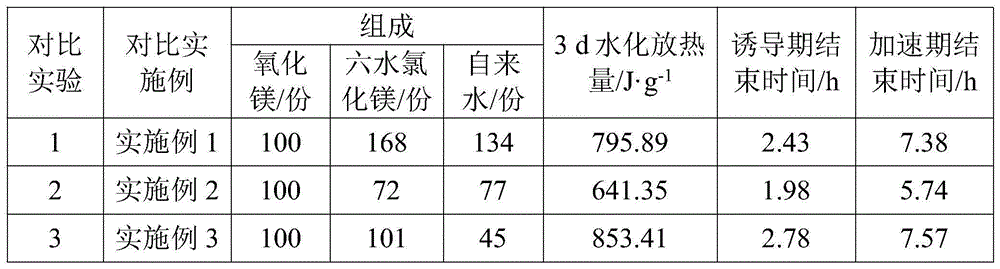

Embodiment 1

[0021] The raw material magnesium oxide is derived from lightly burned magnesite powder, that is, the calcined product of magnesite, and the dosage is about 164 parts. In this embodiment, the content of magnesium oxide is 60% to 62%, that is to say, the raw material magnesium oxide The dosage is about 100 parts.

[0022] Dissolve about 168 parts of magnesium chloride hexahydrate in about 134 parts of tap water to form an aqueous solution of magnesium chloride, where the tap water is the added water, that is, the water added to the system, and the following unless otherwise specified, all refer to this meaning; Add the above-mentioned 164 parts of magnesite light-burnt powder and 1 part of phosphoric acid containing 60% to 62% of the above-mentioned magnesium oxide therein, and form magnesium oxychloride cement after mixing evenly, and the above-mentioned parts are all parts by mass; that is to say, In this magnesium oxychloride cement, the mass ratio of magnesium oxide, magnes...

Embodiment 2

[0026] The raw material magnesium oxide is derived from dolomite lightly burned powder (the content of magnesium oxide is about 20% to 28%), that is, the calcined product of dolomite ore, and the dosage is about 364 parts. Among them, the dolomite lightly burned powder magnesium oxide in this embodiment The content is about 27% to 28%, that is, about 100 parts of magnesium oxide.

[0027] Dissolve 72 parts of magnesium chloride hexahydrate in 77 parts of tap water to form an aqueous magnesium chloride solution, then dissolve 364 parts of the above-mentioned dolomite lightly burned powder and 2 parts of ferroin in the aqueous magnesium chloride solution, and stir to form magnesium oxychloride cement. All are parts by mass; that is to say, in this magnesium oxychloride cement, the mass ratio of magnesium oxide, magnesium chloride and water is 2.8:1:3.2, and the source of water here is described in embodiment 1; And chemical addition The addition amount of agent iron vitriol is 2...

Embodiment 3

[0030] The raw material magnesia comes from the calcined product of magnesium slag, a by-product of lithium extraction in salt lakes, and the dosage is 125 parts. This example contains about 80% of the raw material magnesia for cement preparation, that is, about 100 parts of magnesia.

[0031] Dissolve 101 parts of bischofite (that is, magnesium chloride hexahydrate) in 45 parts of tap water to form an aqueous magnesium chloride solution; then dissolve 125 parts of the above-mentioned calcined product and 3 parts of citric acid in the aqueous magnesium chloride solution, and stir evenly to form magnesium oxychloride cement , the above-mentioned parts are all parts by mass; that is to say, in this magnesium oxychloride cement, the mass ratio of magnesium oxide, magnesium chloride and water is 2.1:1:2.8, and the source of water here is the same as described in Example 1 ; And the amount of chemical admixture citric acid is 3% of the amount of magnesium oxide.

[0032] The hydrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat of hydration | aaaaa | aaaaa |

| Heat of hydration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com