Porcelain pot and preparation method thereof

A technology for ceramic pots and composite ceramics, applied in the field of kitchen utensils, can solve the problems of reduced non-stick performance of pots, unclean surface of pots, damage to nano-silver coating, etc., so as to improve brittleness, inhibit bacteria for a long time, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

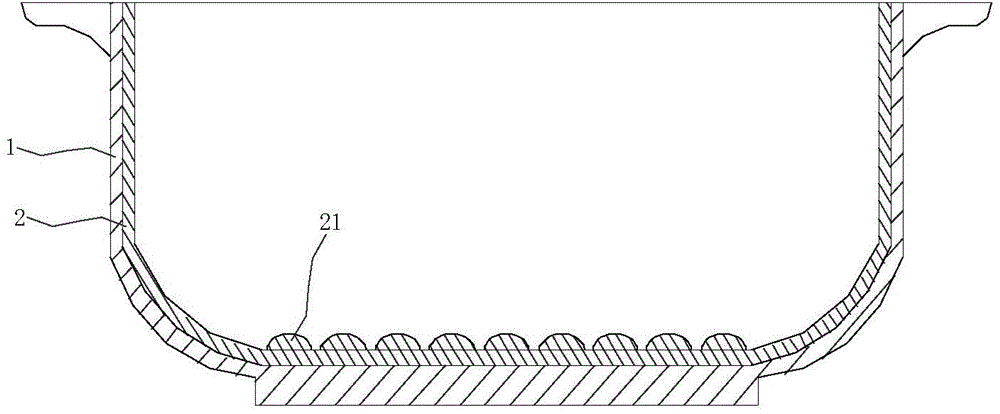

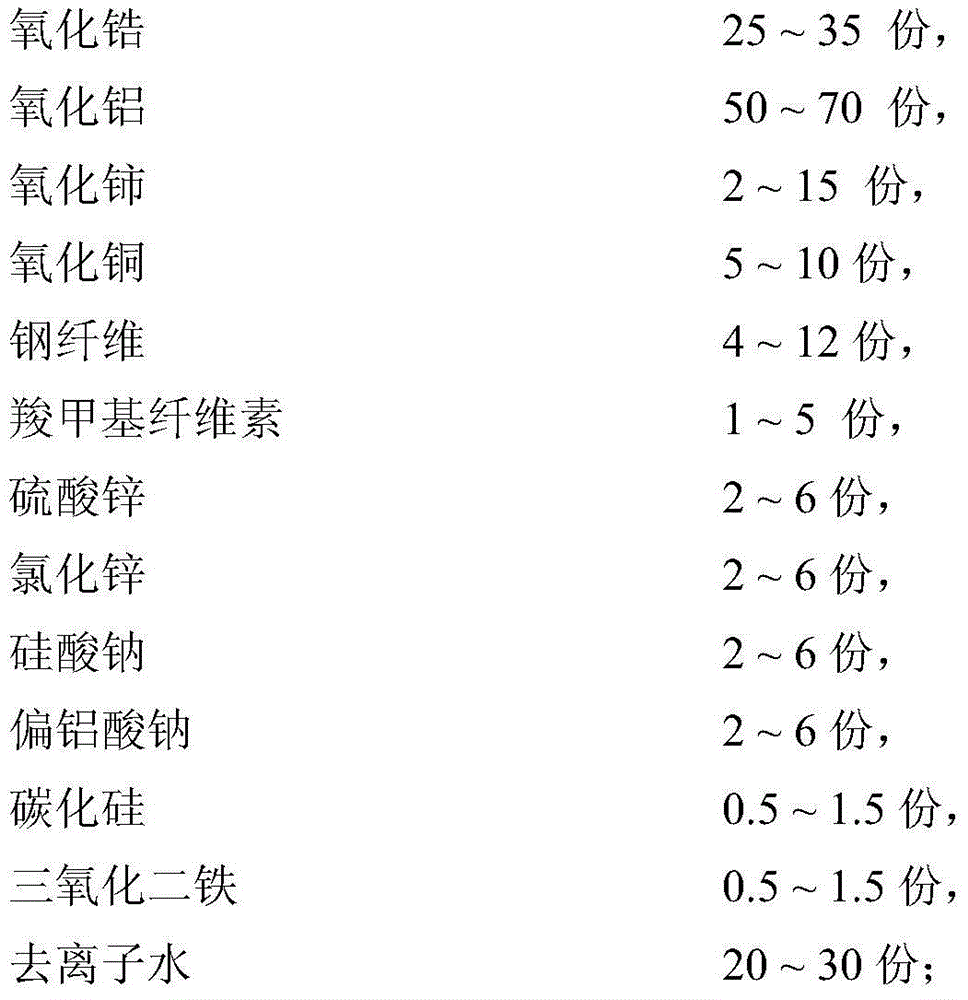

[0035] Such as figure 1 As shown, the ceramic pot of this embodiment includes a pot body 1 and a composite ceramic layer 2 arranged in the pot body 1. The pot body 1 is obtained by molding an aluminum plate or an iron plate, and the upper surface of the bottom of the composite ceramic layer 2 is spaced apart. A plurality of convex hulls 21 are arranged, and the material of the composite ceramic layer 2 includes the following components by weight:

[0036]

[0037] The preparation method of the present embodiment ceramic pan comprises the following steps:

[0038] (1) Preparation of electroless Ni-P alloy coating steel fiber:

[0039] Place steel fibers with a diameter of 20 μm and a length of 10 mm in dilute HCl with a pH value of 5 and a temperature of 40 ° C for 10 minutes, and stir to remove impurities on the surface of the steel fibers, then rinse with water to remove impurities on the surface of the steel fibers. Acids and impurities;

[0040] Use the steel fiber as...

Embodiment 2

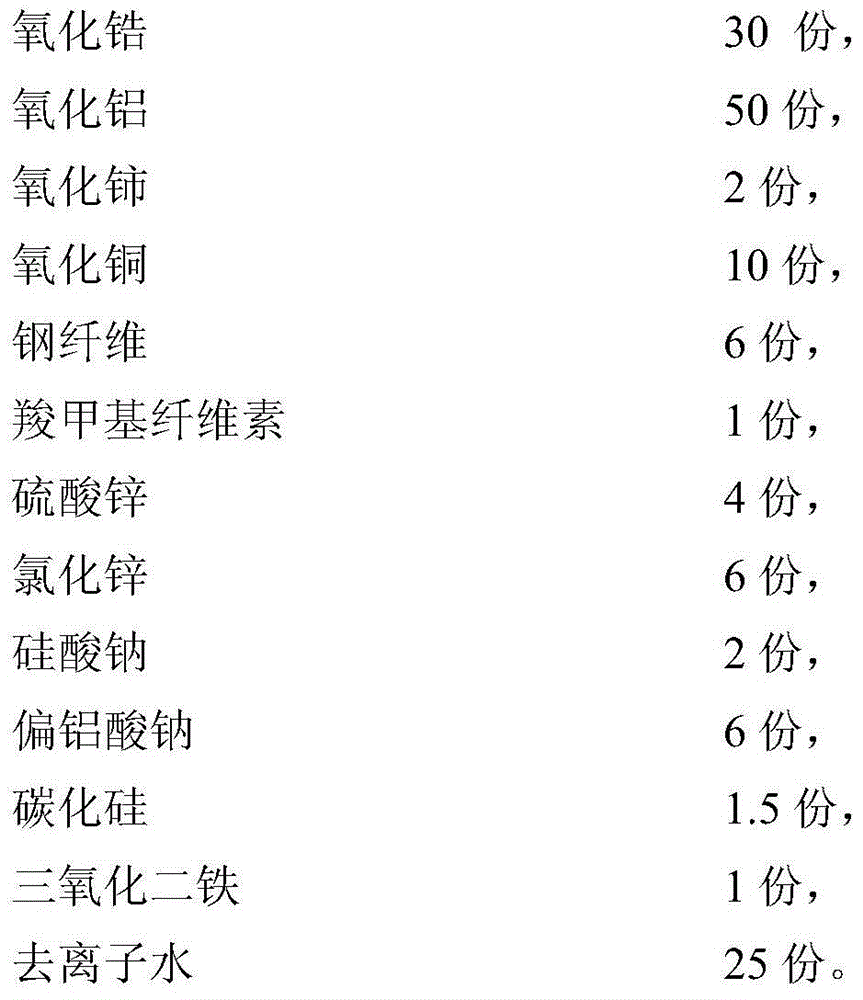

[0054] The difference between this embodiment and Embodiment 1 is that the material of the composite ceramic layer 2 includes the following components by weight:

[0055]

[0056] The preparation method of the present embodiment ceramic pan comprises the following steps:

[0057] (1) Preparation of electroless Ni-P alloy coating steel fiber:

[0058] Place steel fibers with a diameter of 100 μm and a length of 5 mm in dilute HCl with a pH value of 5.1 and a temperature of 42°C for 20 minutes, and stir to remove impurities on the surface of the steel fibers, and then rinse with water to remove the impurities on the surface of the steel fibers. Acids and impurities;

[0059] The steel fiber is used as an anode to electrolytically remove the grease on the surface of the steel fiber by electrochemical method, and then pickled with dilute HCl with a pH value of 5.2. After pickling for 15 minutes, rinse the acid solution on the surface of the steel fiber with clean water;

[00...

Embodiment 3

[0073] The difference between this embodiment and Embodiment 1 is that the material of the composite ceramic layer 2 includes the following components by weight:

[0074]

[0075]

[0076] The preparation method of the present embodiment ceramic pan comprises the following steps:

[0077] (1) Preparation of electroless Ni-P alloy coating steel fiber:

[0078] Place steel fibers with a diameter of 40 μm and a length of 6 mm in dilute HCl with a pH value of 5.2 and a temperature of 45 ° C for 30 minutes, and stir to remove impurities on the surface of the steel fibers, and then rinse with water to remove impurities on the surface of the steel fibers. Acids and impurities;

[0079] Use the steel fiber as an anode to electrolytically remove the grease on the surface of the steel fiber, and then pickle it with dilute HCl with a pH value of 5.1. After pickling for 18 minutes, rinse the acid solution on the surface of the steel fiber with clean water;

[0080] The treated ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com