Catalytic-materail-coated microcrystal bamboo-charcoal pottery bead and preparation method thereof

A catalytic material, a technology of microcrystalline bamboo charcoal, applied in the direction of catalyst activation/preparation, chemical instruments and methods, ceramic products, etc., to achieve the effects of high safety, recovery of catalytic effect, and recovery of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of Microcrystalline Bamboo Charcoal Ceramic Beads

[0042] Mix the raw materials evenly according to the ratio, add water in the granulator to granulate into spherical particles with different particle sizes.

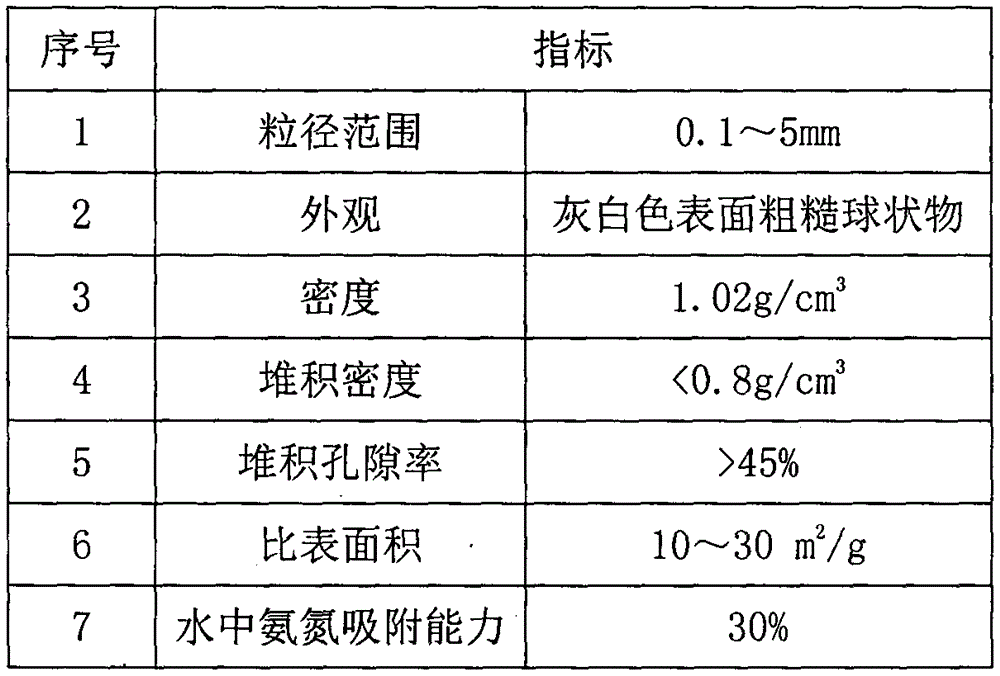

[0043] The average particle size of the used bamboo charcoal powder, porous non-metallic mineral powder and clay is 1-10 μm. The porous non-metallic mineral adopts zeolite, and the clay adopts kaolin. The ingredients are mixed according to the ratio of 40% bamboo charcoal, 30% porous minerals, 25% clay and 5% binder. Add water and starch to the granulator to form spherical granules with a particle size of 0.5mm to 5mm, then air-dry the granules naturally for 24 hours, and then dry them in a drying oven at a temperature of 90°C for 4 hours before anaerobic sintering. Keep at 1250°C for 30 minutes, and cool naturally to obtain pottery pellet products. The performance indicators of the pottery pellets are shown in Table 1.

[0044] Table 1

[0045] ...

Embodiment 2

[0047] Preparation of microcrystalline bamboo charcoal ceramic beads coated with white photocatalytic materials

[0048] Nano TiO 2 The / diatomite composite photocatalytic material is added in the silica sol water dispersion (containing silicon dioxide 30%), vigorously stirred to form a suspension, then the microcrystalline bamboo charcoal pottery beads obtained in Example 1 are put into the suspension, slowly Stir to coat the surface of the microcrystalline bamboo charcoal ceramic beads evenly, then take out the microcrystalline bamboo charcoal ceramic beads and dry them naturally for 4 hours, and then vacuum dry them at 60°C.

Embodiment 3

[0050] Preparation of microcrystalline bamboo charcoal ceramic beads coated with white photocatalytic materials

[0051] Nano TiO 2 The / diatomite composite photocatalytic material is added in the silica sol water dispersion (containing silicon dioxide 30%), vigorously stirred to form a suspension, then the microcrystalline bamboo charcoal pottery beads obtained in Example 1 are put into the suspension, slowly Stir to coat the surface of the microcrystalline bamboo charcoal ceramic beads evenly, then take out the microcrystalline bamboo charcoal ceramic beads and dry them naturally for 4 hours, and then dry them at 200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com