Preparation method of 4,4'-dicarboxy diphenyl ketone

A technology of dimethyl benzophenone and benzophenone, which is applied in the field of preparation of 4,4'-dicarboxybenzophenone, can solve the problems of unmentioned synthesis conditions and operation process, and achieves mild conditions , Overcome the effect of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

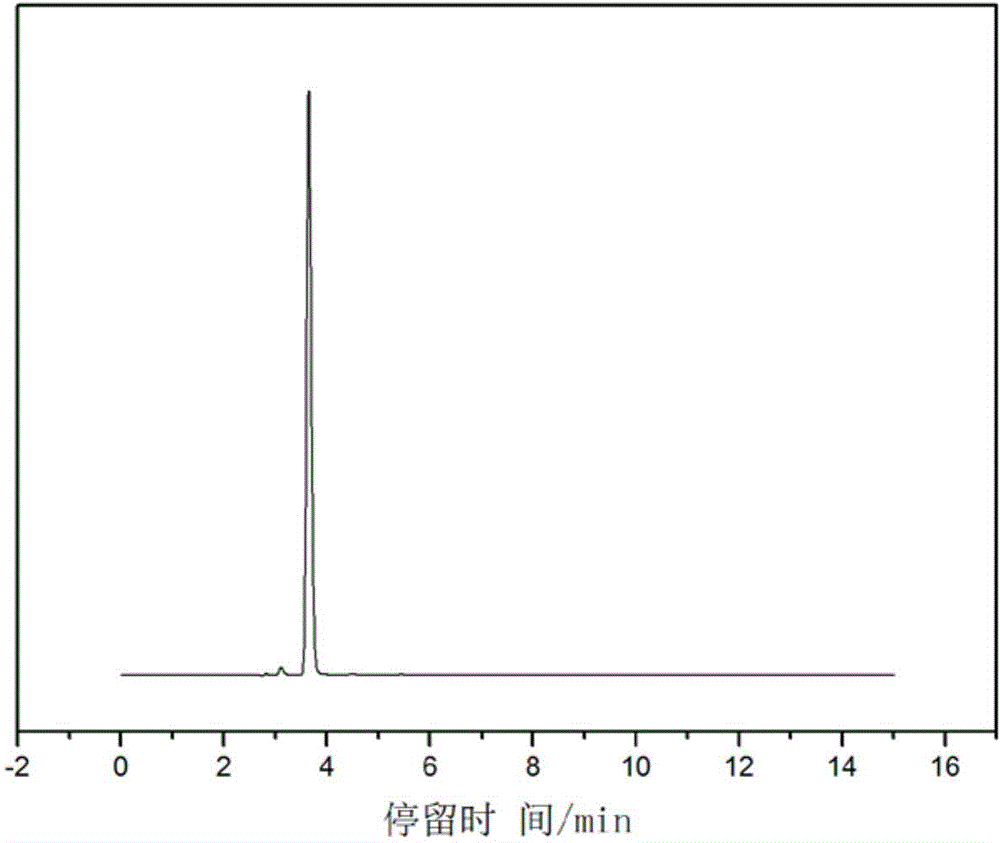

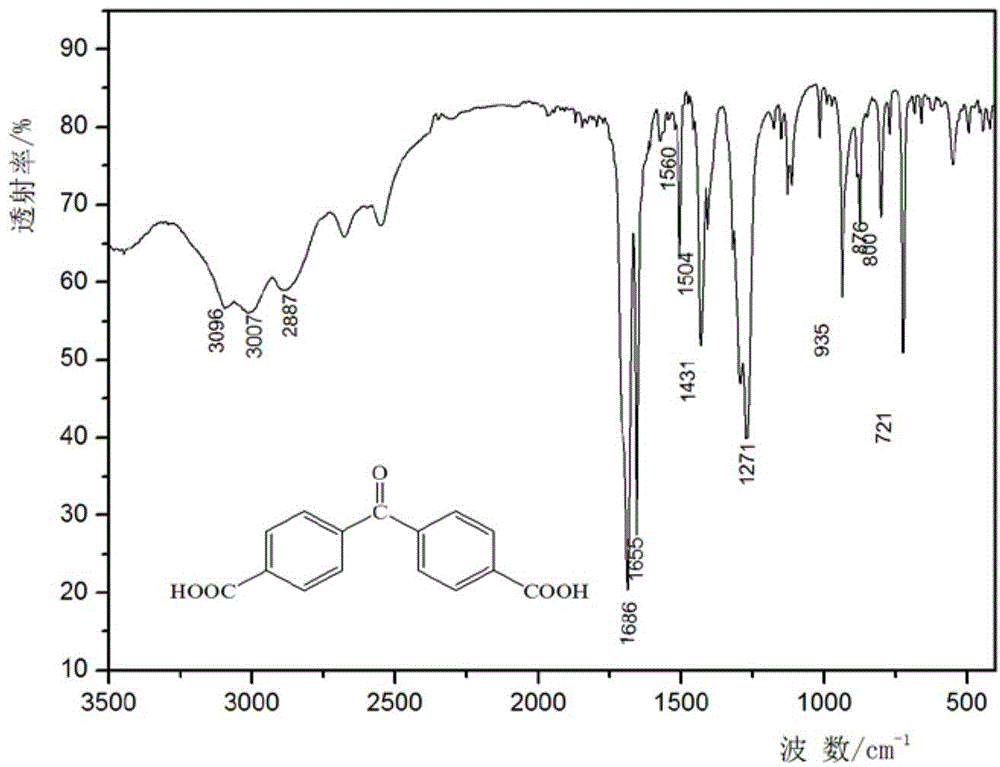

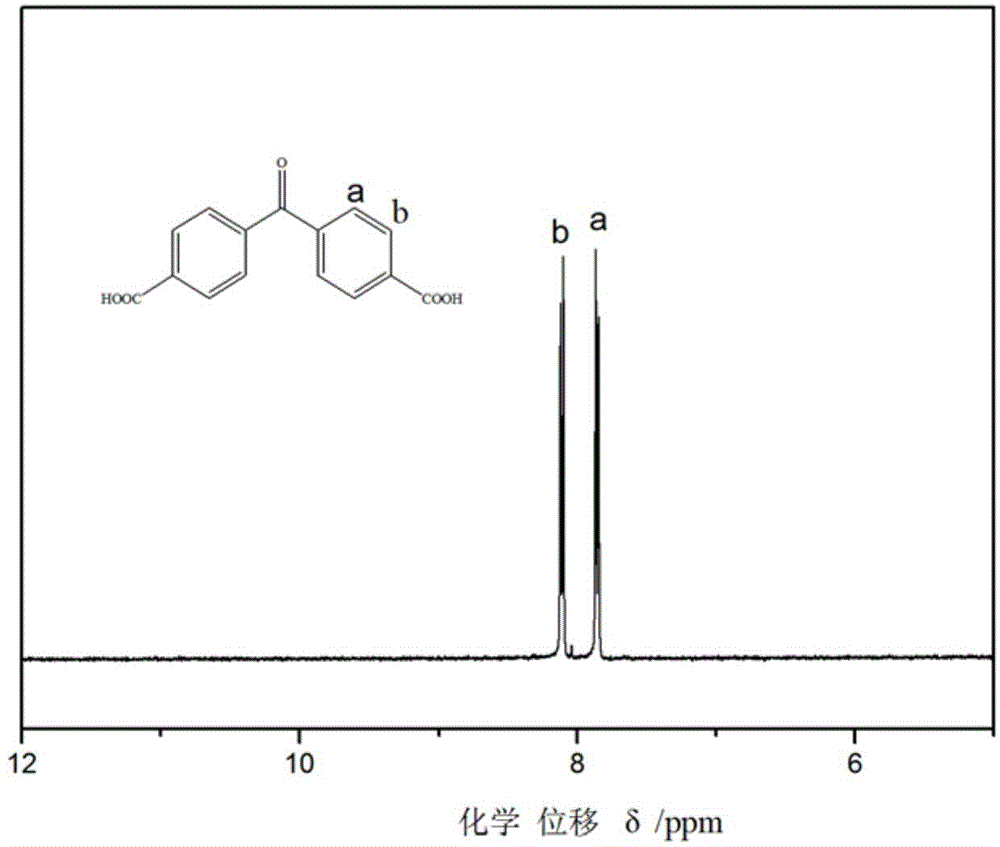

Embodiment 1

[0036] Add 3g (0.014267mol) 4,4'-dimethylbenzophenone, 0.56g (0.00214mol) 18-crown -6, 48ml water, 8.58g (0.07133mol) anhydrous MgSO 4 , the water bath was gradually warmed up to 50°C, and 22.54g (0.14267mol) KMnO was added in batches 4 , KMnO 4 A part was added dropwise in the form of 50ml aqueous solution, and the remaining KMnO 4 Add in portions as a solid. When there is no purple in the system, the reaction ends. Use alkali to adjust the pH of the system to 9-10, filter while it is hot, wash the filter cake twice, filter and combine the filtrate, acidify at 60°C to pH 2-3, at this time, a large amount of white solids are precipitated in the filtrate. Filter, transfer the filter cake to a beaker, add ethanol to wash twice at 65°C, filter, and dry to obtain a white powder product 4,4'-dicarboxybenzophenone (2.56g, yield 66.54%, purity 75.02%).

Embodiment 2

[0038] Add 3g (0.014267mol) 4,4'-dimethyl benzophenone, 0.12g (0.000285mol) trioctyl Methylammonium chloride, 100ml water, 4.29g (0.03566mol) anhydrous MgSO 4 , the water bath was gradually warmed up to 95°C, and 11.27g (0.07133mol) KMnO was added in batches 4 , KMnO 4 A part was added dropwise in the form of 375ml aqueous solution, and the remaining KMnO 4Add in portions as a solid. When there is no purple in the system, the reaction ends. Use alkali to adjust the pH of the system to 9-10, filter while it is hot, wash the filter cake twice, filter and combine the filtrate, acidify at 60°C to pH 2-3, at this time, a large amount of white solids are precipitated in the filtrate. Filter, transfer the filter cake to a beaker, add ethanol to wash twice at 65°C, filter, and dry to obtain a white powder product 4,4'-dicarboxybenzophenone (3.43g, yield 89.11%, purity 98.07%).

Embodiment 3

[0040] Add 3g (0.014267mol) 4,4'-dimethylbenzophenone, 0.47g (0.001426mol) hexadecane Trimethylammonium chloride, 44ml water, 4.29g (0.03566mol) anhydrous MgSO 4 , the water bath was gradually warmed up to 70°C, and 11.27g (0.07133mol) KMnO was added in batches 4 , KMnO 4 A part is added dropwise in the form of 200ml aqueous solution, and the remaining KMnO 4 Add in portions as a solid. When there is no purple in the system, the reaction ends. Use alkali to adjust the pH of the system to 9-10, filter while it is hot, wash the filter cake twice, filter and combine the filtrate, acidify at 60°C to pH 2-3, at this time, a large amount of white solids are precipitated in the filtrate. Filter, transfer the filter cake to a beaker, add ethanol to wash twice at 65°C, filter, and dry to obtain the white powder product 4,4'-dicarboxybenzophenone (3.17g, yield 82.25%, purity 91.67%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com