PP/PA composite material for automobile interior and exterior and preparation method of PP/PA composite material

A technology for automotive interior and exterior decoration and composite materials, applied in the field of PP/PA composite materials, can solve the problems of easy moisture absorption, high cost, waste of energy, etc., achieve improved scratch resistance, improved mechanical properties, and solve the problem of scratch resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

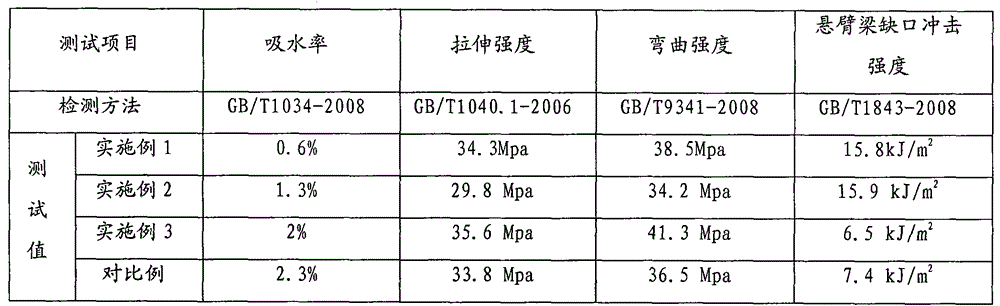

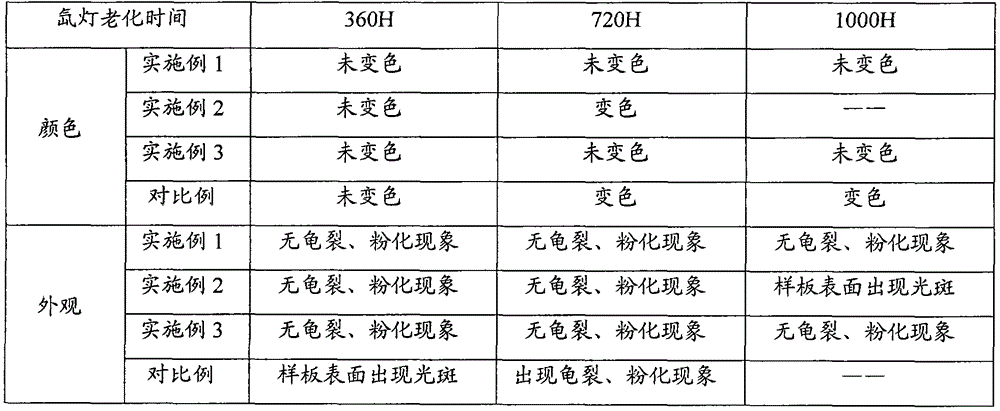

Examples

Embodiment 1

[0024] 1. Preparation of grafts: First dissolve 2kg MAH and 0.1kg DCP with 500ml acetone, add 0.4g antioxidant 1010 powder into 100kg dried block copolymerized polypropylene pellets, stir and mix evenly, pass through twin-screw The extruder is extruded and granulated at 140°C to obtain polypropylene grafted maleic anhydride (PP-g-MAH).

[0025] 2. Modification of talc powder: Add 10kg of talc powder into the high mixing pot, stir at high speed, heat up to 80°C, add 0.3kg of phosphate ester surfactant, continue to heat up to 120°C, unload, and stand for 24 hours for use.

[0026] 3. Preparation of filling masterbatch: 60kg of block copolymerized polypropylene and 1kg of modified talc powder are pre-mixed, mixed, melted and granulated by mixing equipment, and the processing temperature is 160°C.

[0027] 4. Preparation of montmorillonite compound flame retardant: prepared by melt blending 6kg polyphosphoric acid, 2kg pentaerythritol, 2kg melamine and 0.5kg montmorillonite at 120...

Embodiment 2

[0031] 1. Preparation of grafts: first dissolve 3kg MAH and 0.2kg DCP with 800ml acetone, add 0.2g antioxidant 1010 powder into 100kg dried block copolymerized polypropylene pellets, stir and mix evenly, pass through double The screw extruder extruded and granulated at 160°C to obtain polypropylene grafted maleic anhydride (PP-g-MAH).

[0032] 2. Modification of talc powder: Add 10kg of talc powder into a high mixing pot, stir at high speed, heat up to 80°C, add 0.2kg of phosphate ester surfactant, continue to heat up to 120°C, unload, and stand for 24 hours for use.

[0033] 3. Preparation of filling masterbatch: Pre-mix 80kg of block copolymerized polypropylene and 4kg of modified talcum powder, and then knead and melt to granulate through mixing equipment. The processing temperature is 240°C.

[0034] 4. Preparation of montmorillonite compound flame retardant: 16.36kg of polyphosphoric acid, 5.45kg of pentaerythritol, 8.18kg of melamine and 2.5kg of montmorillonite were pre...

Embodiment 3

[0038]1. Preparation of grafts: First dissolve 4kgMAH and 0.4kg DCP with 1000ml acetone, add 0.3g antioxidant 168 powder into 100kg dried block copolymerized polypropylene pellets, stir and mix evenly, pass through twin-screw The extruder is extruded and granulated at 180°C to obtain polypropylene grafted maleic anhydride (PP-g-MAH).

[0039] 2. Modification of talc powder: Add 10kg of talc powder into a high mixing pot, stir at high speed, heat up to 80°C, add 0.5kg of phosphate ester surfactant, continue to heat up to 120°C, unload, and stand for 24 hours for use.

[0040] 3. Preparation of filling masterbatch: pre-mix 70kg of block copolymerized polypropylene and 2.5kg of modified talcum powder, and mix and melt granulate through mixing equipment, and the processing temperature is 200°C.

[0041] 4. Preparation of montmorillonite compound flame retardant: 11.54kg of polyphosphoric acid, 3.85kg of pentaerythritol, 4.62kg of melamine and 1.5kg of montmorillonite were prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com