Heat-conducting insulated epoxy resin composition and preparation method and use thereof

A technology of epoxy resin and epoxy resin, applied in the field of materials, can solve the problems of reducing the dielectric properties of epoxy resin, and achieve the effect of large particle size and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

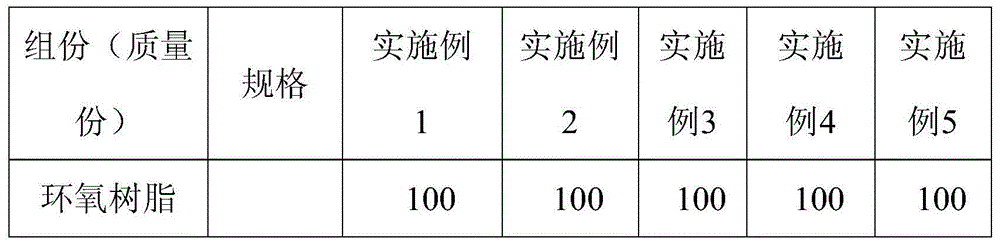

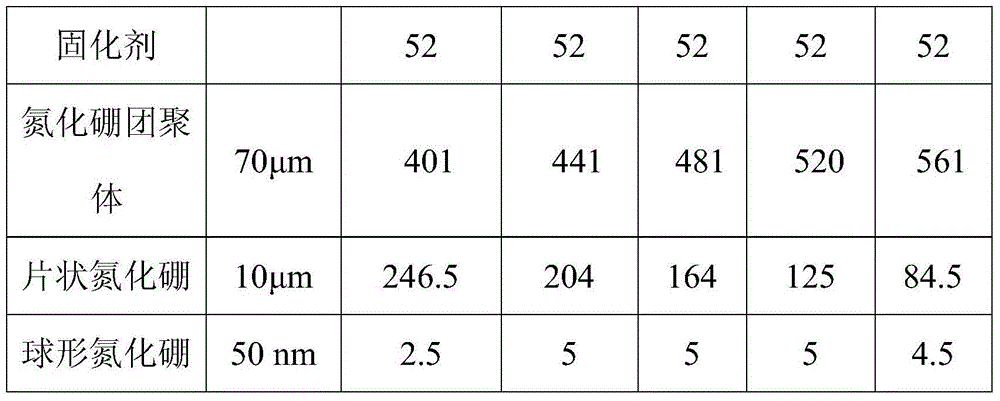

Embodiment 1-5

[0070] According to Table 1, the component C boron nitride agglomerates of the formula amount, the component D (a) micron plate-shaped boron nitride, and the component D (b) nano-spherical boron nitride are mixed uniformly by a mixer to obtain a filler mixture . Epoxy resin, curing agent, filler mixture, and solvent methyl ethyl ketone are uniformly dispersed and mixed by ultrasonic dispersion, and then further mixed by a high-speed mixer such as the high-speed mixer DISPERMAT of VMA-Getzmann Company, and the solvent is removed under high-temperature vacuum to form an uncured ring. oxygen composition. The uncured epoxy composition was poured into a preheated mold, and cured under a pressure of 50 MPa. The curing conditions were 115°C for 15 hours, and then 140°C for 12 hours.

[0071] The boron nitride aggregates, micron flake boron nitride, and nano-spherical boron nitride used in Examples 1-5 of the present invention are all surface treated, and the surface treatment agent ...

Embodiment 6-10

[0089] According to Table 5, the component C and the component D are mixed uniformly by a mixer to prepare a filler mixture. Epoxy resin, curing agent, filler mixture, and solvent methyl ethyl ketone are uniformly dispersed and mixed by ultrasonic dispersion, and then further mixed by a high-speed mixer such as the high-speed disperser DISPERMAT of VMA-Getzmann Company, and the solvent is removed under high temperature and vacuum to form an uncured ring. oxygen composition. The uncured epoxy composition was poured into a preheated mold, and cured under a pressure of 30MP. The curing condition was 105°C for 20h, and then 130°C for 16h.

[0090] The boron nitride aggregates, micron flaky boron nitride, micron ellipsoidal aluminum nitride, nano-spherical alumina, and nano-spherical silicon dioxide used in Examples 6-10 of the present invention are all surface treated, and the surface treatment agent is γ ~Glycidoxypropyltrimethoxysilane.

[0091] The formula and properties of t...

Embodiment 11-15

[0097] According to Table 1, the component C boron nitride agglomerates of the formula amount, the component D (a) micron plate-shaped boron nitride, and the component D (b) nano-spherical boron nitride are mixed uniformly by a mixer to obtain a filler mixture . Epoxy resin, curing agent, filler mixture, and solvent methyl ethyl ketone are uniformly dispersed and mixed by ultrasonic dispersion, and then further mixed by a high-speed mixer such as the high-speed mixer DISPERMAT of VMA-Getzmann Company, and the solvent is removed under high-temperature vacuum to form an uncured ring. oxygen composition. The uncured epoxy composition was poured into a preheated mold, and cured under a pressure of 70MP. The curing condition was 125°C for 8 hours, and then 150°C for 7 hours.

[0098] The formulations and properties of the epoxy resin compositions of Examples 11-15 of the present invention are listed in Table 7 and Table 8, respectively.

[0099] The epoxy resin composition formul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com