A mineral oil defoamer

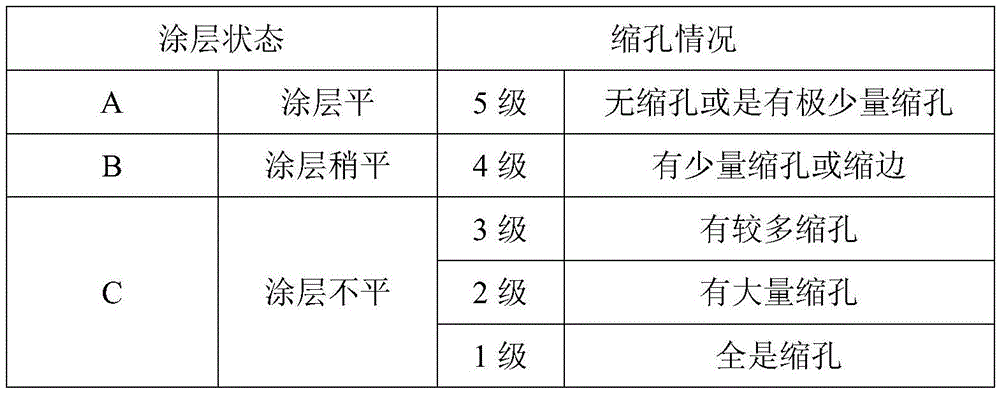

A technology of defoaming agent and mineral oil, applied in the direction of coating, etc., can solve problems such as poor defoaming and suppressing performance, coating defects, poor coating defects, etc., to improve defoaming and suppressing performance and stability, and solve shrinkage craters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

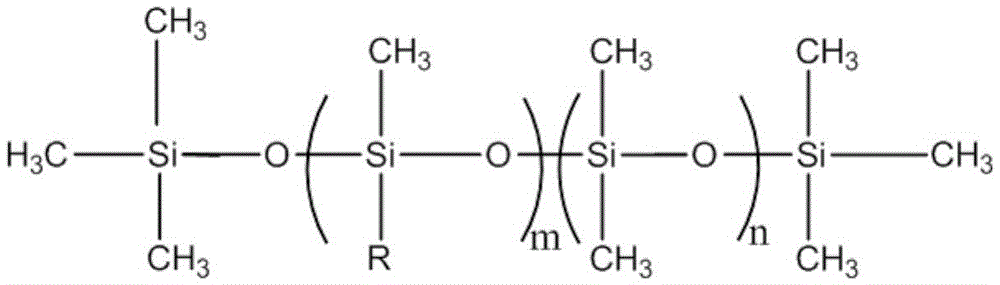

[0038] Mix 21g of alkyl silicone oil (the average carbon number is 1.3, and the number of carbon atoms in the group R is 10) and 2g of precipitated silica, and disperse at a high speed of 2000rpm for 10min, and raise the temperature to 100°C, keep warm After 0.5h, the mixture A was obtained, and the kinematic viscosity reached 3000mPa·s at 25°C.

[0039] Then add 317g5# white oil, 577g peanut oil and epoxidized peanut oil thereof in the container, add 9g aluminum hexadecanoate while stirring, 13g aluminum dioctoate, 23g oxidized polyethylene wax, 25g stearic acid, and above-mentioned mixture A , and then continue to stir for 15min. Immediately after slowly raising the temperature to 140°C and keeping it warm for 0.5h, then cooling down to 80°C, adding 18g of sorbitan trioleate (Span-85) and continuing to stir for 60min to obtain mixture B.

[0040]At room temperature, the mixture B was dispersed in a high-speed disperser at a speed of 3000 rpm until the size of the particles ...

Embodiment 2

[0042] Mix 96g of alkyl silicone oil (the average carbon number is 2.1, and the number of carbon atoms in the group R is 14) and 45g of precipitated silica, and disperse at a high speed of 2000rpm for 10min, and raise the temperature to 160°C, keep warm Mixture A was obtained in 2h, and the kinematic viscosity reached 4000mPa·s at 25°C.

[0043] Then add 127g7# white oil, 673g soybean oil and its amidated soybean oil in container, add 30g bis(docosanoate) aluminum while stirring, 0.5g polyoxypropylene glycol, 0.5g n-stearyl alcohol, With the above mixture A, and then continue to stir for 10min. Immediately after slowly raising the temperature to 180°C and keeping it warm for 3h, then cooling down to 80°C, adding 28g of polyoxyethylene sorbitan trioleate (Tween-85) and continuing to stir for 60min to obtain mixture B.

[0044] At room temperature, the mixture B was dispersed in a high-speed disperser at a speed of 3000 rpm until the size of the particles was in the range of 5-...

Embodiment 3

[0046] Mix 11g of alkyl silicone oil (the average carbon number is 4.1, and the number of carbon atoms in the group R is 18) and 4g of precipitated silica, and disperse at a high speed of 2000rpm for 10min, and raise the temperature to 130°C, keep warm Mixture A was obtained in 1.2h, and the kinematic viscosity reached 5000mPa·s at 25°C.

[0047] Then add 170 alkylbenzenes, 630g castor oil and epoxidized castor oil thereof in the container, add 20g aluminum di(octadecanoate) while stirring, 15g isobutyl phosphate, 10g ethylene glycol diester stearate , and the above mixture A, and then continue to stir for 30min. Immediately after slowly raising the temperature to 140°C and keeping it warm for 3h, then cooling down to 60°C, adding 140g of oleic acid polyoxyethylene (6) ether, and continuing to stir for 60min to obtain mixture B.

[0048] At room temperature, the mixture B was dispersed in a high-speed disperser at a speed of 3000 rpm until the size of the particles ranged fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com