Method for producing fuel oil by hydrogenation of high temperature coal tar distillate oil

A technology of high-temperature coal tar and distillate oil, which is applied in the field of coal chemical industry, can solve the problems of difficult operation, coking of catalysts, high asphalt content, etc., and achieve the effects of prolonging the operation cycle, easing reaction heat release, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

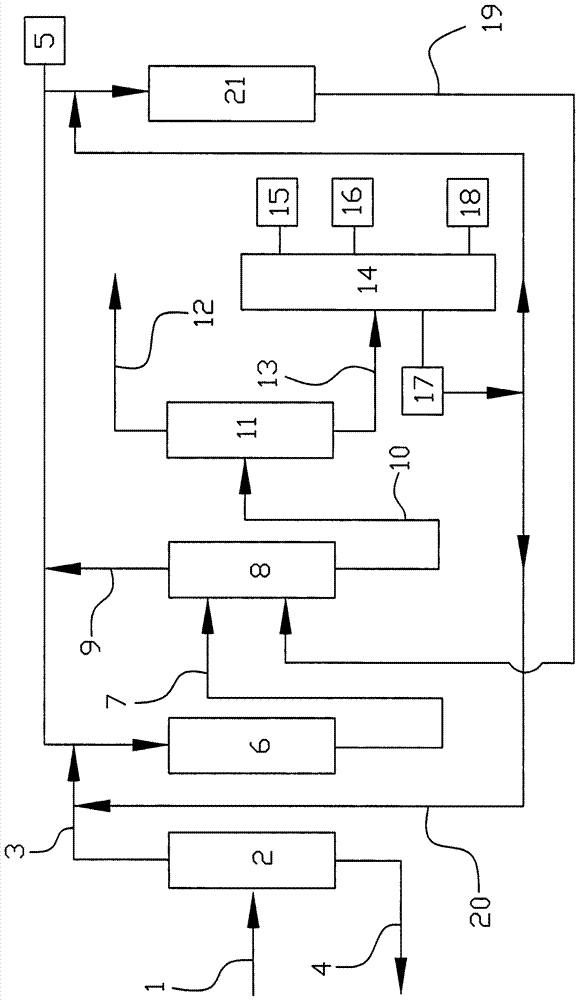

[0022] The method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the method for producing fuel oil by hydrogenation of high-temperature coal tar distillates in the present embodiment comprises the following steps:

[0024] a. High-temperature coal tar 1 is fractionated at a temperature of 350-400°C to obtain light fraction 3 and heavy fraction 4;

[0025] b. The light fraction 3 described in the step a is mixed with the hydrogen 5 and enters the hydrofinishing reaction zone 6, where the hydrogenation protection catalyst and the hydrofinishing catalyst are successively contacted in the refining reaction zone 6 for hydrogenation reaction;

[0026] c, the effluent 7 after the reaction in the hydrofinishing reaction zone 6 enters the separation zone 8 for gas-liquid separation, and the gas phase product 9 obtained by separation is returned to the hydrofinishing reaction zone 6 and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com