Lubricating oil and preparation method thereof

A lubricating oil and mineral oil technology, applied in the field of lubricating oil, can solve the problems of depletion of biodegradable resources, environmental pollution, low non-renewability, etc., and achieve the effects of excellent environmental stability, good compatibility, and improved antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

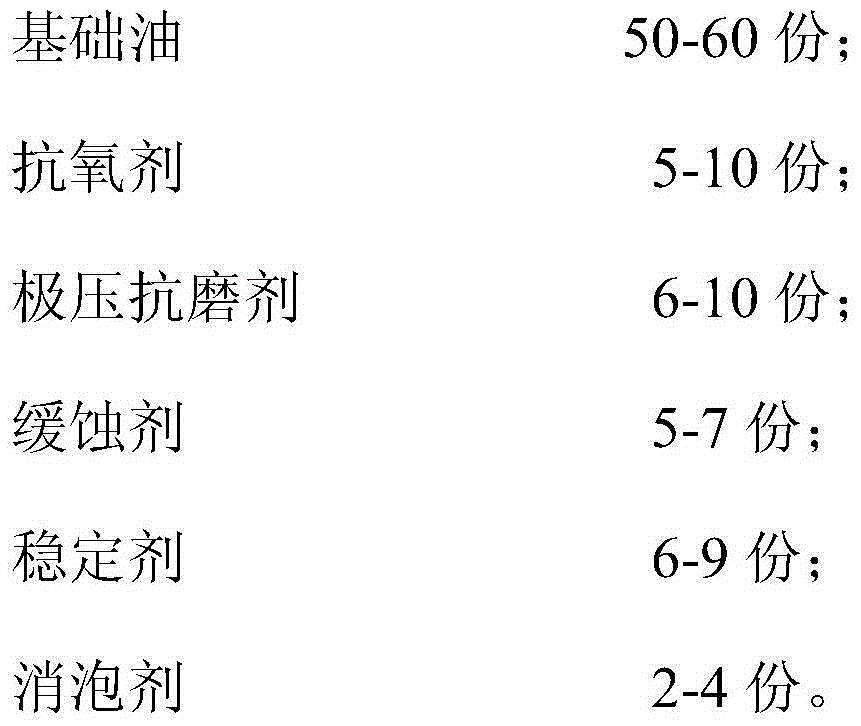

[0036] Embodiment 1: a kind of lubricating oil is that the following raw materials form through deployment, and all parts are parts by weight:

[0037]

[0038] Lubricating oil preparation method of the present invention is as follows:

[0039] (1) According to the ratio of molar ratio n dodecene:n octadecene=1:2, add dodecene and octadecene to the polymerization kettle at one time, add 0.5wt% metallocene catalyst, and gradually raise the temperature to 80°C , After reacting for 3 hours, stop the reaction to obtain poly-alpha-olefin latex.

[0040] (2) Add polyalphaolefin and II type mineral oil into the raw material miscibility tank, and naturally miscible for 30 minutes to obtain lubricating oil base oil;

[0041] (3) Add antioxidants, extreme pressure antiwear agents, corrosion inhibitors, stabilizers, and defoamers to the above base oil, stir for 1 hour at normal temperature and pressure, then let stand for 12 hours, filter to remove mechanical impurities, and obtain ...

Embodiment 2

[0042] Embodiment 2: a kind of lubricating oil is that the following raw materials are formulated, and all parts are parts by weight:

[0043]

[0044] Lubricating oil preparation method of the present invention is as follows:

[0045] (1) According to the ratio of molar ratio n dodecene:n octadecene=1:2.4, add dodecene and octadecene to the polymerization kettle at one time, add 0.8wt% metallocene catalyst, and gradually raise the temperature to 90°C , After reacting for 4h, stop the reaction to obtain poly-alpha-olefin latex.

[0046] (2) Add polyalphaolefin and II type mineral oil into the raw material miscibility tank, and naturally miscible for 35 minutes to obtain lubricating oil base oil;

[0047] (3) Add antioxidants, extreme pressure antiwear agents, corrosion inhibitors, stabilizers, and defoamers to the above base oil, stir for 1 hour at normal temperature and pressure, then let stand for 14 hours, filter to remove mechanical impurities, and obtain Lubricating ...

Embodiment 3

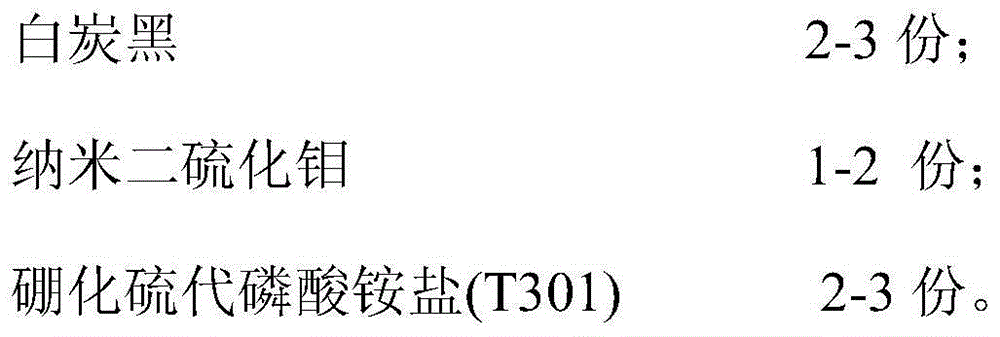

[0048] Embodiment 3: a kind of lubricating oil is that the following raw materials are formulated, and all parts are parts by weight:

[0049]

[0050]

[0051] Lubricating oil preparation method of the present invention is as follows:

[0052] (1) According to the ratio of molar ratio n dodecene: n octadecene=1:3, add dodecene and octadecene to the polymerization kettle at one time, add 1.8wt% metallocene catalyst, and gradually raise the temperature to 110°C , After reacting for 5h, stop the reaction to obtain poly-alpha-olefin latex.

[0053] (2) Add polyalphaolefin and II type mineral oil into the raw material miscibility tank, and naturally miscible for 38min to obtain lubricating oil base oil;

[0054] (3) Add antioxidants, extreme pressure antiwear agents, corrosion inhibitors, stabilizers, and defoamers to the above base oil, stir for 2 hours at normal temperature and pressure, then let stand for 16 hours, filter to remove mechanical impurities, and obtain Lubr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com