Phase change heat storage device and method utilizing engine waste gas waste heat

A phase change heat storage and engine technology, applied in exhaust devices, engine components, combustion engines, etc., can solve the problems of large volume, cold start or long warm-up time, etc., and achieve a small size, simple structure, and easy to start. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

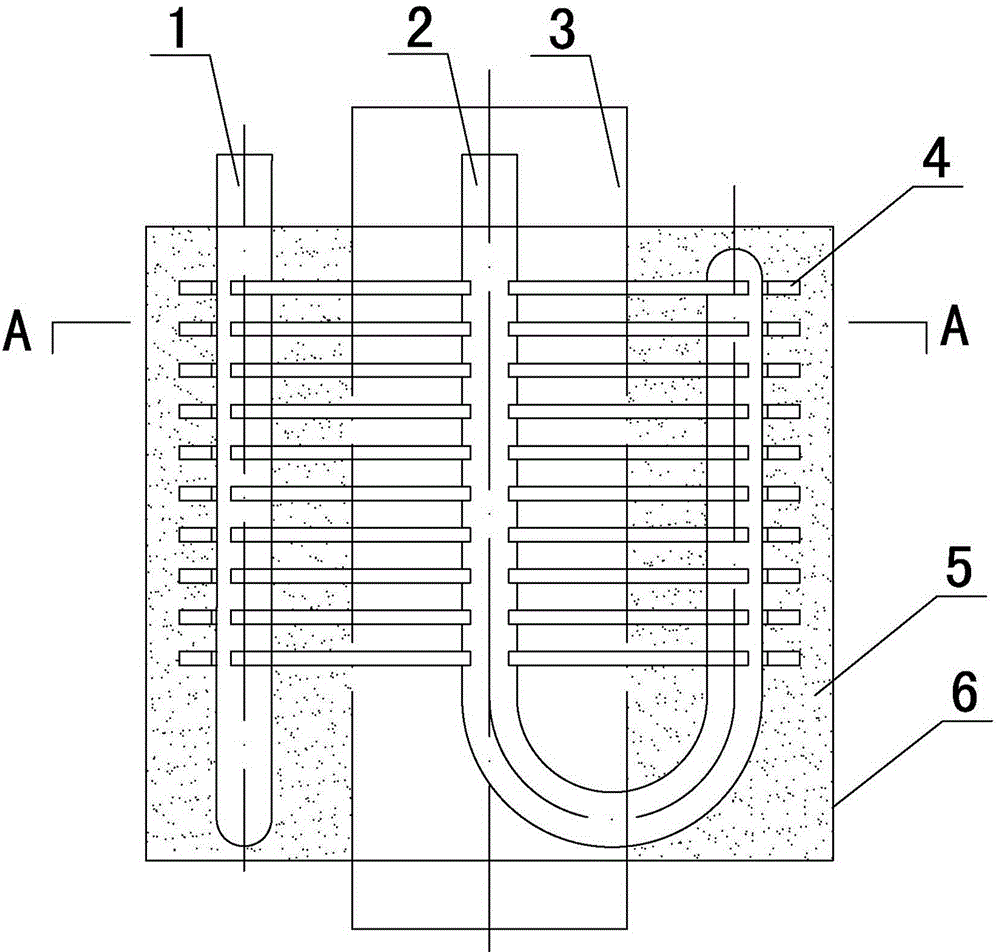

[0023] The phase change thermal storage device utilizing the waste heat of engine exhaust gas in this embodiment, such as figure 1 shown. The device includes hot fluid pipes 3 , heat exchange fins 4 , cold fluid pipes and sleeves 6 . The hot fluid pipeline 3 is connected with the exhaust pipe of the engine, and the heat exchange fin 4 is fixedly connected outside the heat fluid pipeline 3. The edge of the heat exchange fin 4 is provided with a slot, and the cold fluid pipe is clamped in the slot. A sleeve 6 is arranged outside the heat exchange fins 4 and the cold fluid pipe, and a phase change material 5 is arranged between the hot fluid pipe 3 and the sleeve 6 .

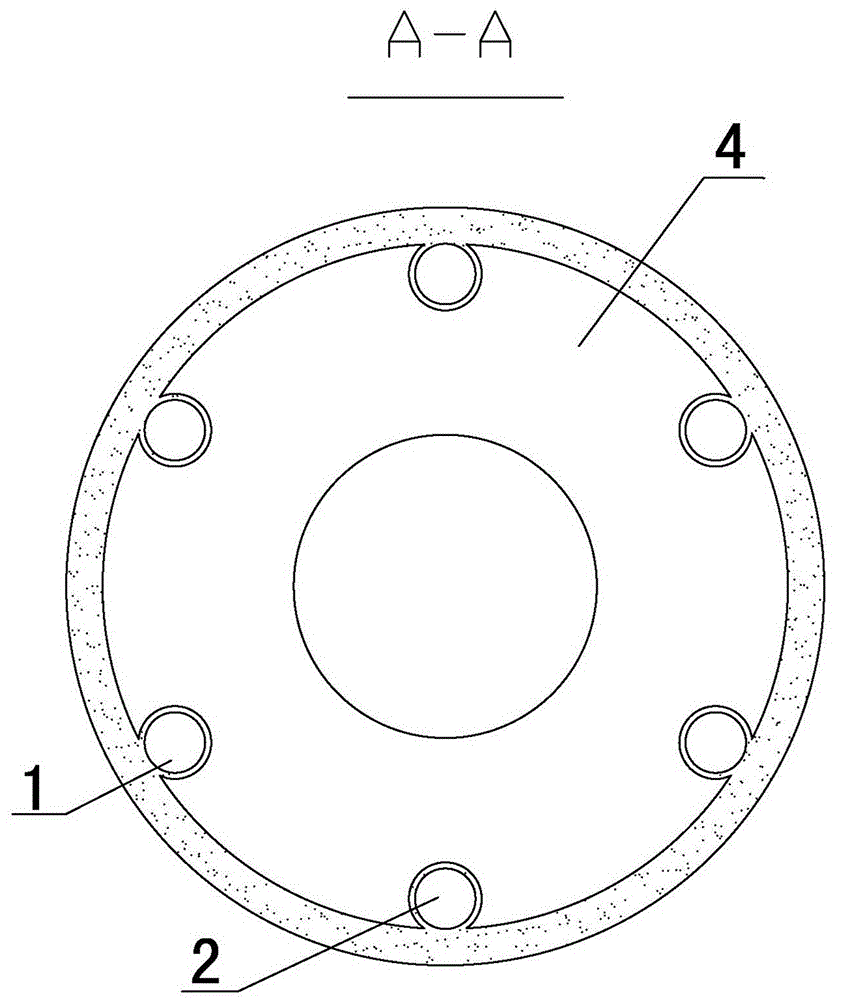

[0024] The cold fluid flows into the phase change heat storage device from the cold fluid inlet 1, and flows out of the phase change heat storage device through the cold fluid outlet 2, such as figure 2 shown.

Embodiment 2

[0026] The difference between the phase change heat storage device of this embodiment and Embodiment 1 is that the heat exchange fins 4 are annular fins.

Embodiment 3

[0028] The difference between the phase change heat storage device of this embodiment and that of Embodiment 1 is that: sleeve heads are provided at both ends of the sleeve 6, and the sleeve 6 and the heads at both ends of the sleeve are welded together. The sleeve and sleeve head are made of stainless steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com