Method for testing content of calcium carbonate in paper-making process regenerated tobacco leaf

A technology for reconstituting tobacco leaves and calcium carbonate, applied in the direction of removing certain components and weighing, etc., can solve the problems of cumbersome operation, high analysis cost, inability to accurately reflect the content of calcium carbonate, etc., and achieve fast analysis speed, repeatability and stability. Good performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

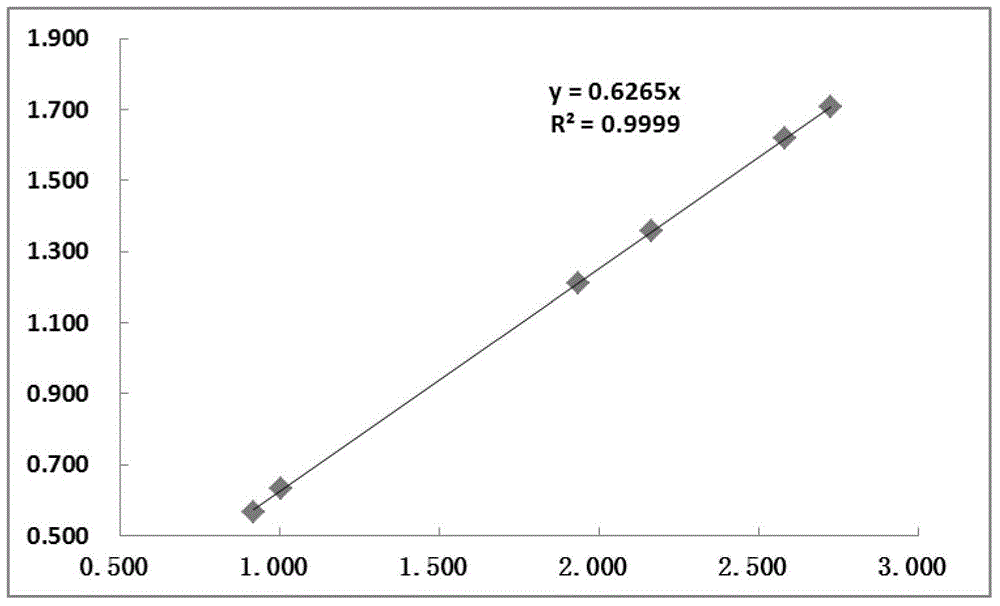

[0023] Weigh the mass m from a sample of reconstituted tobacco leaf 1 Put 1.051g of reconstituted tobacco leaves with a moisture content w of 11.70% in a triangular flask, add 100mL of hot water, and extract the water-soluble components in the reconstituted tobacco leaves. The extraction time is 1h, and the weighed mass m 0 1.460g of filter paper is placed in a Buchner funnel, the extract is vacuum filtered, washed 3 times, taken out and dried in an oven at a drying temperature of (105±1)°C for 5 hours, taken out and placed in a silica gel desiccator to cool 30min, take it out, weigh the filter paper and the first residue m 2 The mass of is 2.065g;

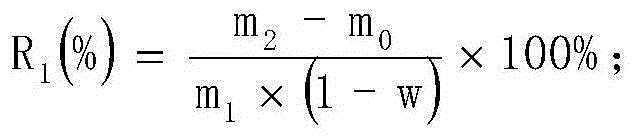

[0024] Calculate the percentage of residue in the first batch: R 1 ( % ) = m 2 - m 0 ...

Embodiment 2

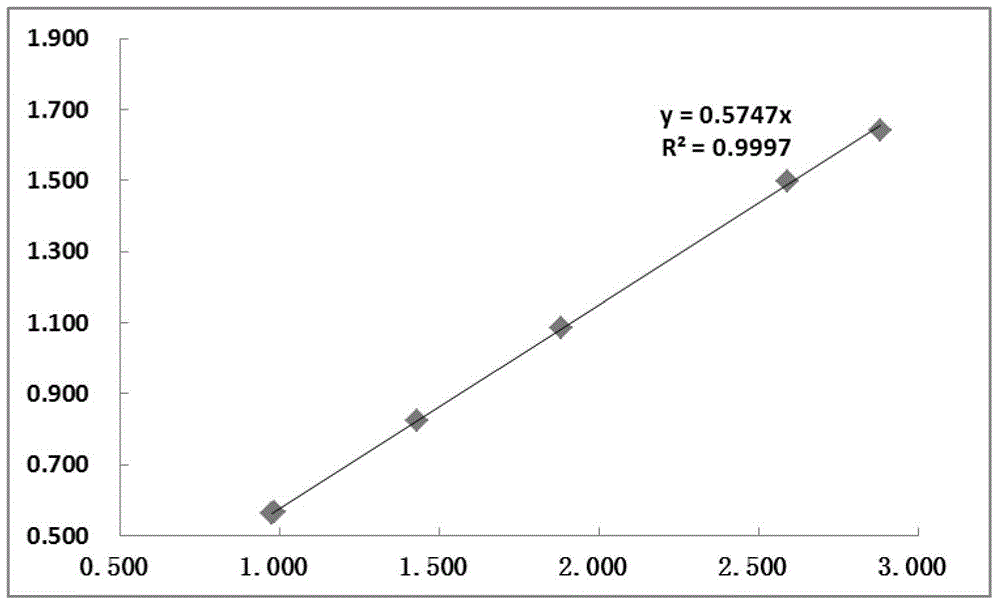

[0029] Weigh the mass m from a sample of reconstituted tobacco leaf 1 Put 1.324g of reconstituted tobacco leaves with a water content of 11.70% into a conical flask, add 50mL of hot water at 100°C, extract the water-soluble components in the reconstituted tobacco leaves, and extract the water-soluble components in the reconstituted tobacco leaves for 2 hours. 0 1.465g of filter paper is placed in a Buchner funnel, the extract is vacuum filtered, washed 3 times, taken out and dried in an oven at a drying temperature of (105±1)°C for 5 hours, taken out and placed in a silica gel desiccator to cool 30min, take it out, weigh the filter paper and the first residue m 2 The mass of is 2.227g;

[0030] Calculate the percentage of residue in the first batch: R 1 ( % ) = m 2 - m ...

Embodiment 3

[0035] Weigh the mass m from a sample of reconstituted tobacco leaf 1 Put 1.386g of reconstituted tobacco leaves with a water content of 11.70% in a conical flask, add 50mL of hot water at 98°C to 100°C, and extract the water-soluble components in the reconstituted tobacco leaves. The extraction time is 1.5h, and the weighed mass m 0 1.468g of filter paper is placed in a Buchner funnel, the extract is vacuum filtered, washed 3 times, taken out and dried in an oven at a drying temperature of (105±1)°C for 5 hours, taken out and placed in a silica gel desiccator to cool 30min, take it out, weigh the filter paper and the first residue m 2 The mass of is 2.165g;

[0036] Calculate the percentage of residue in the first batch: R 1 ( % ) = m 2 - m 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com