Preparation methods of controllable arrayed nanowires and FET (field effect transistor) comprising controllable arrayed nanowires

A nanowire and array technology, which is applied in the field of field effect transistor preparation, can solve the problems of poor controllability, difficulty in obtaining large-area array nanowires, and difficulty in realizing controllable array nanowires, and achieves low cost and controllability. Strong, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

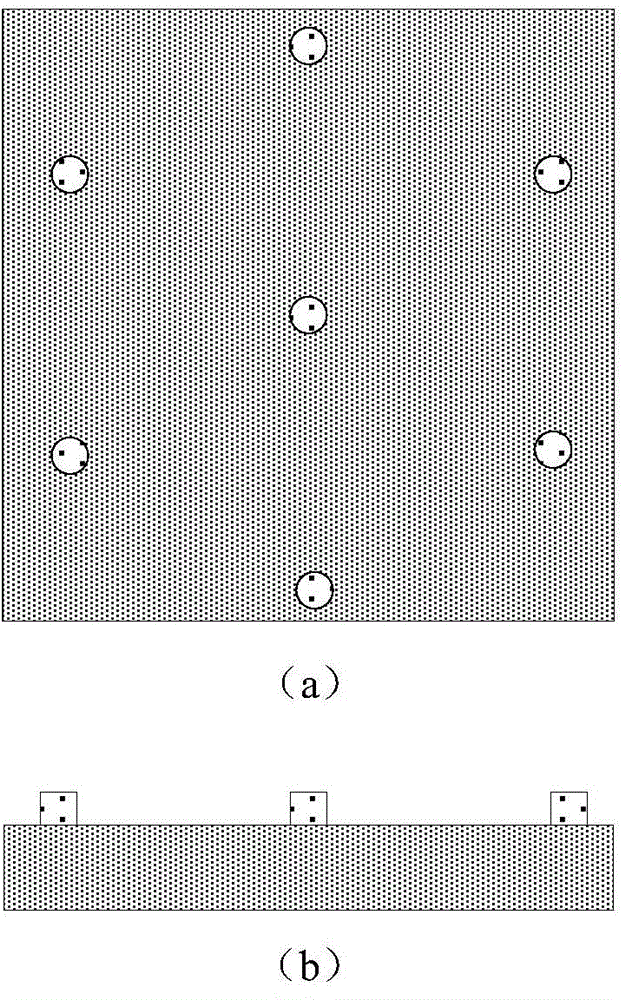

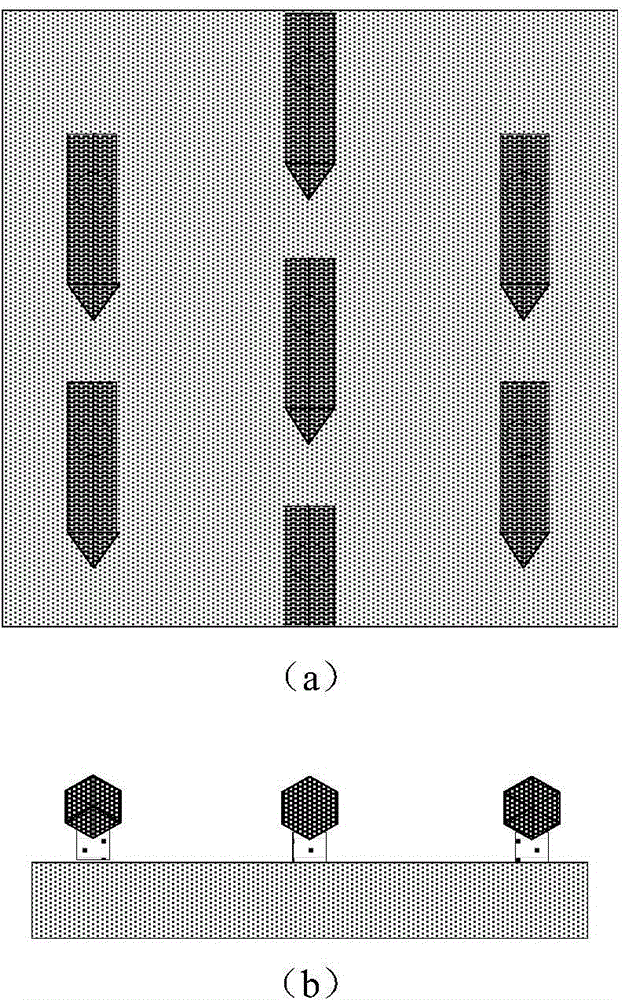

[0045] In this embodiment, the GaN controllable array nanowires are prepared, and the substrate adopts GaN; the pattern of the patterned substrate is a periodic columnar two-dimensional lattice; the growth material of the array nanowires is GaN; the growth method of the array nanowires adopts Molecular beam epitaxy MBE in The growth process is carried out in an ultra-high vacuum growth chamber, and the high-purity (7N) metal source is generated by a K-Cell source furnace; the nitrogen source uses a radio frequency plasma nitrogen source; the growth process uses a reflective High-energy electron diffractometer RHEED in-situ monitoring.

[0046] The preparation method of the controllable array nanowires of this embodiment includes the following steps:

[0047] 1) Select the growth material with anisotropic growth rate along different crystal directions as the substrate:

[0048] The growth rate of wurtzite GaN along the [0001] direction is much faster than that along the an...

Embodiment 2

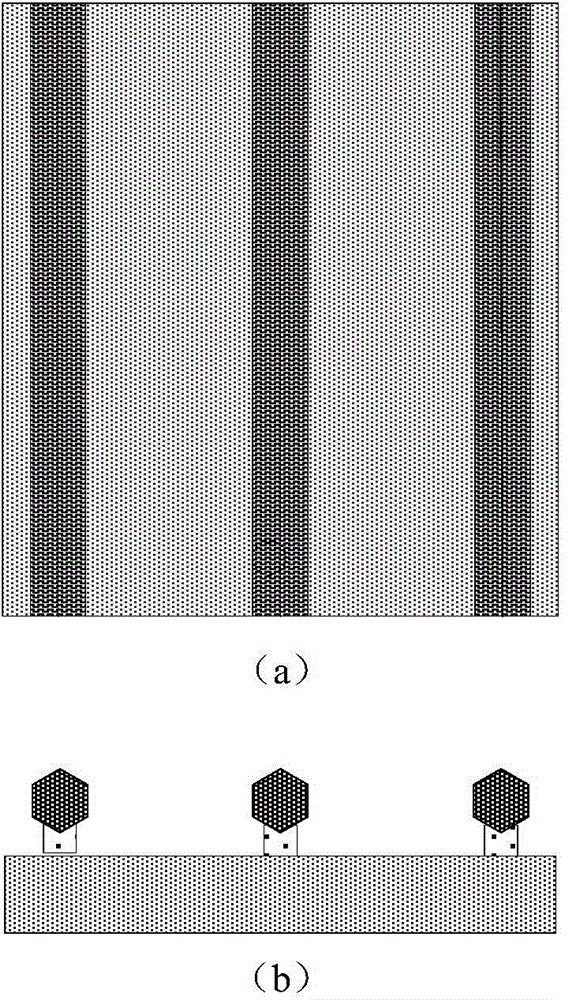

[0060] In this embodiment, a GaN controllable array nanowire FET is prepared, and the substrate is GaN; the pattern of the patterned substrate is a periodic hole-like two-dimensional lattice; the growth material of the array nanowire is GaN; the growth of the array nanowire The method uses molecular beam epitaxy (MBE) in The growth process is carried out in an ultra-high vacuum chamber, and the high-purity (7N) metal source is generated by a K-Cell source furnace; the nitrogen source is a radio frequency plasma nitrogen source; the growth process uses a reflection RHEED in situ monitoring.

[0061] The preparation method of the controllable array nanowire FET of this embodiment includes the following steps:

[0062] 1) Select the growth material with anisotropic growth rate along different crystal directions as the substrate:

[0063] The growth rate of wurtzite GaN along the [0001] direction is much faster than that along the and The growth rate in the direction, choos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com