Compound type embossing photovoltaic welding strip and machining method thereof

A photovoltaic ribbon and processing method technology, applied in photovoltaic power generation, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as hidden dangers, high production costs, desoldering and virtual welding, etc., to increase production costs, High production efficiency and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific drawings and embodiments.

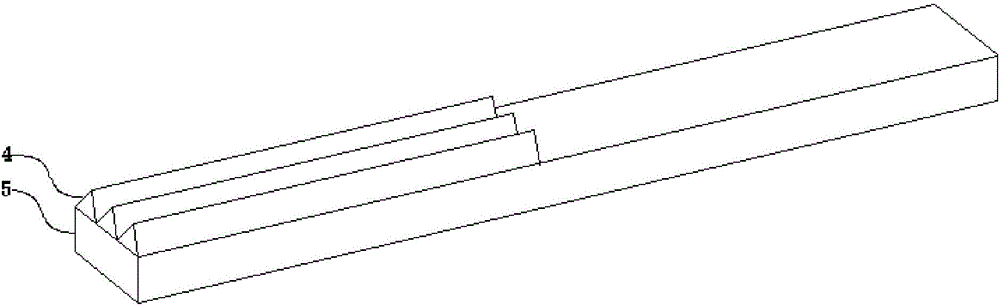

[0027] The composite embossed photovoltaic ribbon proposed by the present invention is as image 3 As shown, it includes a strip-shaped conductive base material 5 for welding with the bus bar on the solar cell sheet, and the strip-shaped conductive base material 5 can adopt a tinned copper strip base material; on the strip-shaped conductive base material 5 upper surface Several special-shaped metal wires 4 capable of reflecting light are placed on one side; the material of the special-shaped metal wires 4 can be pure copper or silver. If pure copper is used, the outer surface should be dipped with a layer of solder. The maximum length of the solar cell, usually the solar cell is square, the length of the special-shaped metal wire 4 is equal to the length of the solar cell or slightly less than the length of the solar cell;

[0028] The cross-sectional shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com