High-efficiency high-yield preparation method of panax notoginseng extract

An extraction and high-yield technology, applied in the field of medicine, can solve the problems of loss of active ingredients of Panax notoginseng, long time of percolation, and difficulty in industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

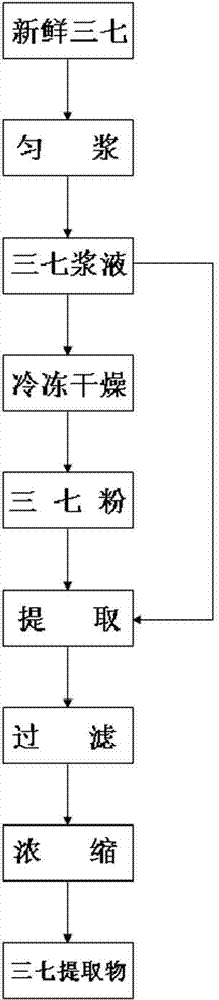

[0016] The high-efficiency and high-yield preparation method of the Radix Notoginseng extract of the present invention uses fresh Radix Notoginseng as a raw material, and obtains it through homogenization, freeze-drying, and extraction steps, specifically comprising:

[0017] A. Homogenization: Take fresh Sanqi as raw material, add water with a weight ratio of 0.05 to 0.50 times to homogenate to obtain Panax notoginseng slurry;

[0018] B. Freeze-drying: Freeze-drying the notoginseng slurry prepared in step A to obtain notoginseng powder;

[0019] C. Extraction:

[0020] Method 1: add an ethanol solution with a weight ratio of 3 to 8 times to the notoginseng slurry prepared in step A, extract at a temperature of 20 to 35°C for 0.5 to 3.0 hours, filter and concentrate to obtain the target notoginseng extract;

[0021] Method 2: Add the notoginseng powder prepared in step B to an ethanol solution with a weight ratio of 5 to 15 times, extract at a temperature of 20 to 35°C for 1...

Embodiment 1

[0035] Take 50 kg of fresh Panax notoginseng, add 15 kg of water and 5 kg of ice cubes, and homogenize it in a homogenizer for 40 minutes to obtain a panax notoginseng slurry. Add 8 times the weight of 60% ethanol solution to the slurry and extract at 20°C for 3 hours. The extract was filtered under reduced pressure to remove the filter residue, and the filtrate was concentrated and dried under reduced pressure to obtain the target Panax notoginseng extract.

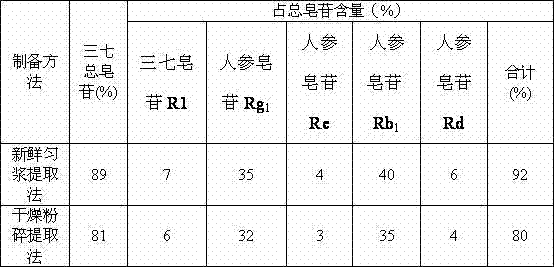

[0036] It has been tested that the Panax notoginseng extract contains 83% of the total saponins of Panax notoginseng, of which Panax notoginseng saponin R1 accounts for 8%, ginsenoside Rg 1 Accounted for 32%, ginsenoside Re accounted for 5%, ginsenoside Rb 1 Accounted for 37%, ginsenoside Rd accounted for 9%, accounting for 91% of the total saponins.

Embodiment 2

[0038] Take 80kg of fresh Panax notoginseng, add 40kg of water and 18kg of ice cubes, and homogenize it in a homogenizer for 45 minutes to obtain a panax notoginseng slurry. Add 3 times the weight of 90% ethanol solution to the slurry and extract at 35°C for 0.5h. The extract was filtered under reduced pressure to remove the filter residue, and the filtrate was concentrated and dried under reduced pressure to obtain the target Panax notoginseng extract.

[0039] After testing, the Panax notoginseng extract contains 89% of the total saponins of Panax notoginseng, of which Panax notoginsenoside R1 accounts for 7%, ginsenoside Rg 1 34%, ginsenoside Re 4%, ginsenoside Rb 1 Accounted for 39%, ginsenoside Rd accounted for 8%, accounting for 92% of the total saponins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com