Compound functional primary settling tank, system containing compound functional primary settling tank and application of system

A composite function, primary sedimentation tank technology, applied in the direction of settling tank, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. impact and other issues, to achieve the effect of saving power consumption and reducing operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

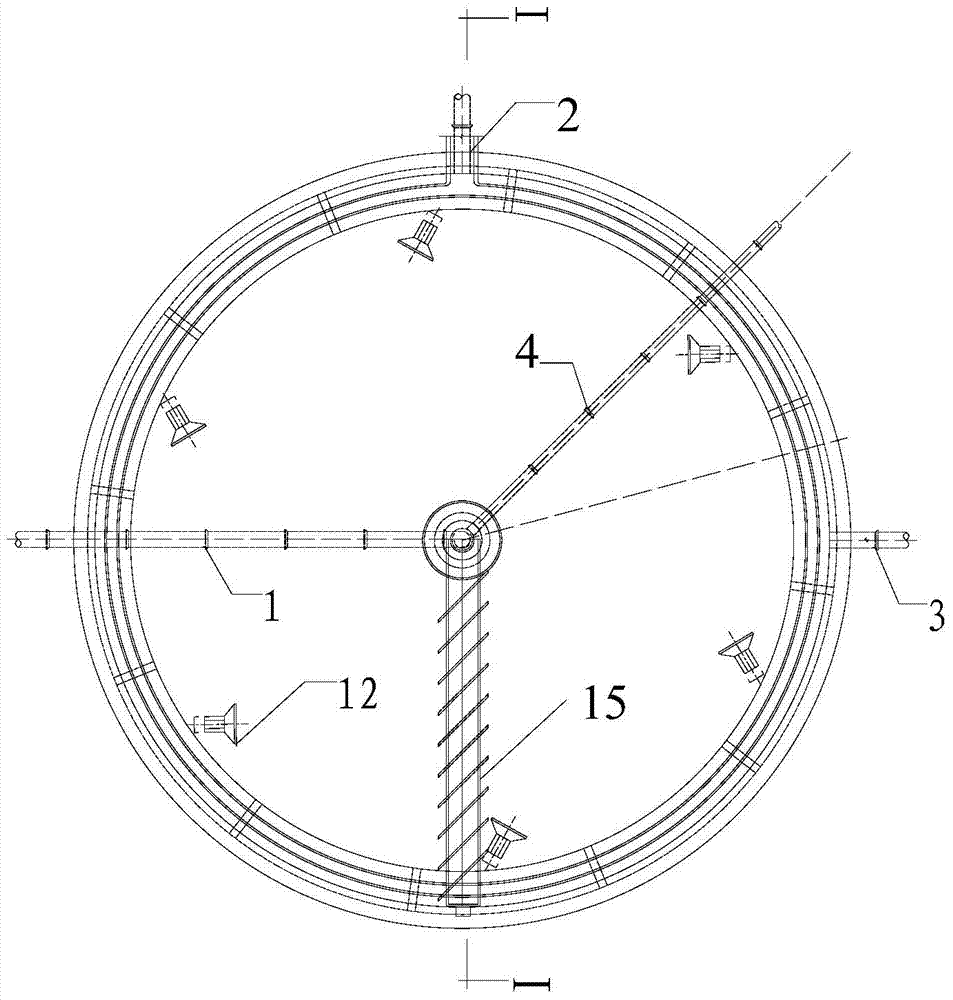

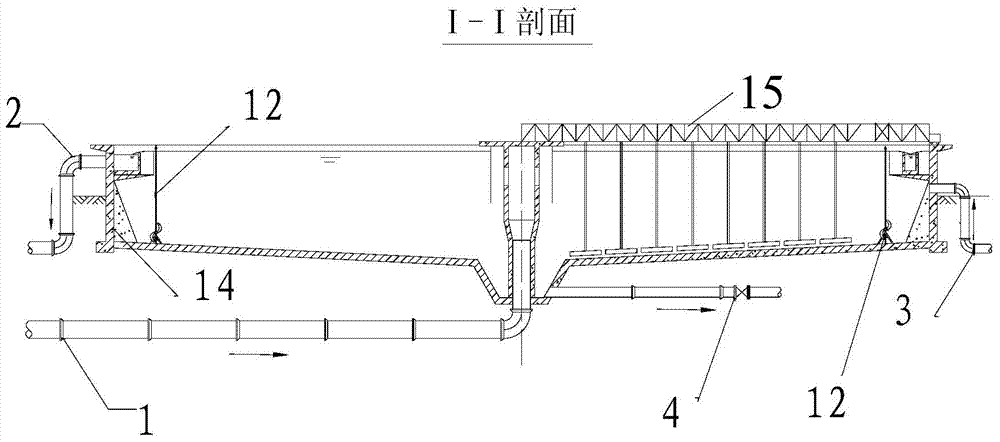

Embodiment 1

[0061] A sewage treatment plant has a treatment capacity of 150,000 tons per day. The original treatment process is primary sedimentation tank-biological tank-secondary sedimentation tank. The biological tank is divided into anaerobic and aerobic two parts. The hydraulic retention time (HRT) of the primary sedimentation tank is 3.2 hours, and the HRT of the biological tank is 7.5 hours. The effluent reaches the secondary standard of the "Comprehensive Wastewater Discharge Standard". After the sewage treatment plant implements standard upgrading and transformation, it is required to increase the nitrogen and phosphorus removal function, and the effluent should meet the first-class A standard. Limited by the site, the sewage treatment plant can only expand a group of biological pools, and the HRT of the biological pools is 10h. When the temperature is low in winter, it still cannot meet the requirements of denitrification and dephosphorization treatment. Therefore, the primary s...

Embodiment 2

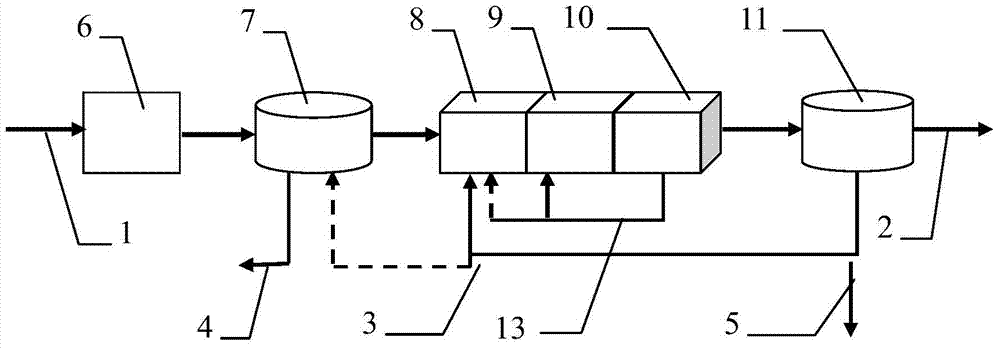

[0068] Embodiment 2: normal operation mode

[0069] See image 3 . In summer, when the water temperature reaches above 20°C, the influent BOD / TN is greater than 4, BOD / COD is greater than 0.3, and the water quality is good, the composite primary sedimentation tank operates as an ordinary sedimentation tank. The submersible thruster in the composite primary sedimentation tank stops running, and the mud scraper runs normally; the sludge return point is in the anaerobic (anoxic) pool of the biological reaction tank, and the reflux ratio is 70-100% of the influent, and the anaerobic (anoxic) The oxygen tank is used for anaerobic phosphorus release. The microporous aerator in the transition tank is closed, the submersible thruster is running, the internal return sludge point is in the transition tank, the internal return ratio is 200%, and the transition tank is used for denitrification. The microporous aerator in the aerobic pool is turned on for nitrification. The HRT of anae...

Embodiment 3

[0070] Embodiment 3 hydrolysis sedimentation tank mode operation

[0071] See Figure 4 . When the water temperature is above 20°C and BOD / COD is less than 0.3, the composite sedimentation tank operates in the hydrolysis sedimentation tank mode. 3 sets of submersible thrusters in the compound primary sedimentation tank are running and 3 sets are stopped, agitating the bottom sludge to form a suspended sludge layer, and the mud scraper is running. The operating mode of the biological pool is the same as the normal operating mode.

[0072] The effluent water quality of the composite primary sedimentation tank tends to be stable, and the small molecule easily degradable organic matter increases, increasing the B / C to about 0.3, which is beneficial to the subsequent biological treatment. The HRT of primary sedimentation hydrolysis, anaerobic phosphorus release, denitrification and nitrification are 3.2h, 3.5h, 3h, 3.5h respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com