Ultramicro droplets manipulator based on liquid residues and method thereof

A control device and ultra-trace technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problem of difficult to accurately control the volume of ultra-trace liquid, achieve easy arraying and automation, reduce sample size and reagent consumption, enabling arraying and automating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

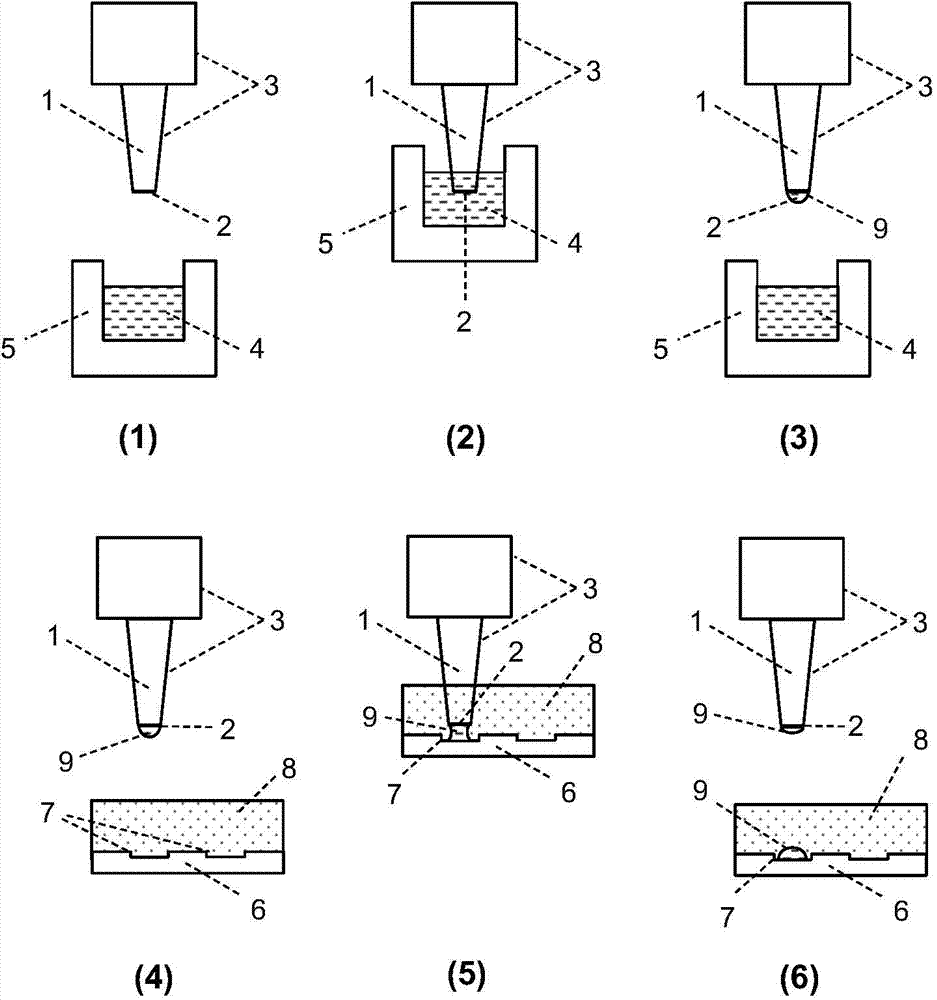

[0041] figure 1 It is a schematic diagram of the ultra-micro droplet manipulation method based on liquid residue in Example 1.

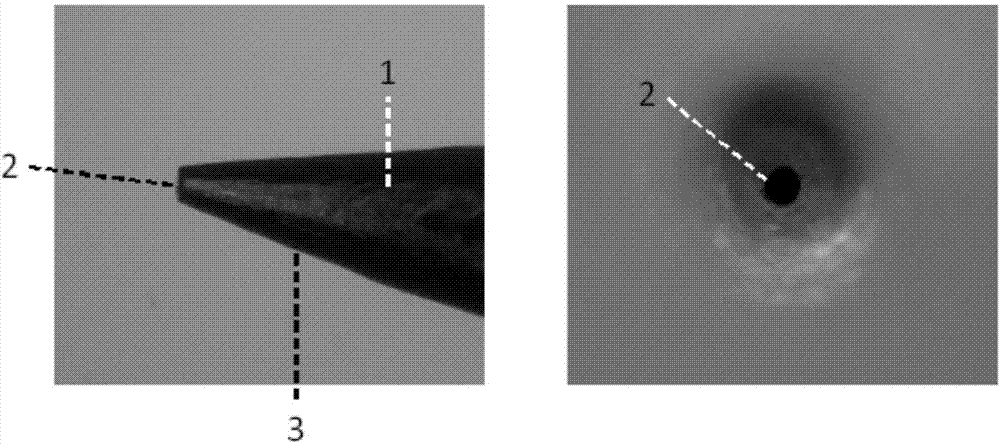

[0042] A stainless steel pin (600 microns in diameter) is used as the liquid-taking probe 1. First, the surface of the cleaned liquid-taking probe 1 is subjected to overall hydrophobic treatment with chemical reagents, and then the tip of the liquid-taking probe 1 is polished on sandpaper. Finally, the tip cross-section (60 microns in diameter) is obtained as the liquid-taking probe 1 with hydrophilicity and the remaining surfaces are hydrophobic, wherein the hydrophilic tip cross-section is used as the liquid-taking end 2 of the liquid-taking probe 1, and the The radius of the cross-sectional area of the liquid end 2 is about 30 microns; the surface of the liquid-taking probe 1 with hydrophobicity is used as the supporting part 3 of the liquid-taking probe 1 ( image 3 ). will be 10 -3 M (mol / L) sodium fluorescein solution was added into a comm...

Embodiment 2

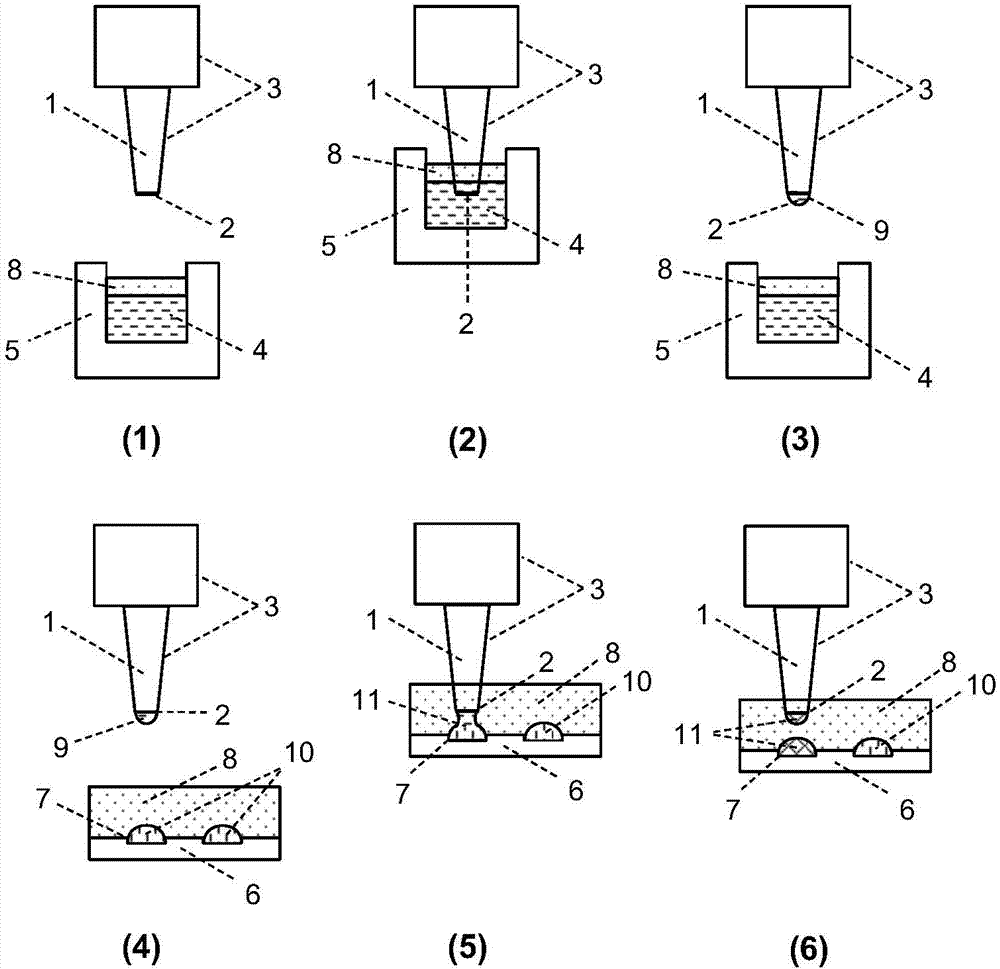

[0049] Figure 5 It is a schematic diagram of the ultra-micro droplet manipulation method based on liquid residue in Example 2.

[0050] ABS plastic processing cylindrical rod (diameter 1.8 mm, length 40 mm) is used as the liquid-taking probe 1, and the surface of the liquid-taking probe 1 does not need to be surface treated, and it is only simply cleaned before use. The circular cross-section of the top of the cylinder of the liquid-taking probe 1 is used as the liquid-taking end 2 of the liquid-taking probe 1 , and the other parts of the liquid-taking probe 1 are used as the supporting part 3 of the liquid-taking probe 1 . The other ends of the six liquid-taking probes 1 or their supporting parts 3 are fixed on a support plate to form a one-dimensional sampling probe array 12. In order to match the commercial 384-well plate, the adjacent liquid-taking probes 1 The spacing between the 4.5 mm ( Figure 5 ). will be 10 -3 M sodium fluorescein solution was added into six wells...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com