Cleaning method for repairing heavy metal contaminated soil

A technology for polluted soil and heavy metals, applied in the restoration of polluted soil and other directions, can solve problems such as difficulty in meeting engineering requirements, low repair cost, damage to soil structure, etc., to reduce the risk of secondary pollution, avoid chemical waste, and restore the effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

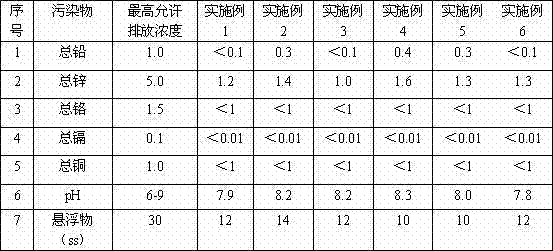

Examples

Embodiment 1

[0033] The oxidant is hydrogen peroxide (commercially available, concentration 30%), 5mL is added to 300mL water, and shaken for 0.5h; the cleaning agent is hydrochloric acid (commercially available, concentration 37%) 2.5mL + calcium chloride (commercially available 3.3g, shaken for 1h; Cleaning solution (242mL) was obtained after liquid separation, and a pH regulator was added to the cleaning solution. Sodium hydroxide (10mol / L, 6.5mL) was used to adjust the pH value to 8-9. The flocculant was polyacrylamide PAM (commercially available ) 0.6mg, stand still.

Embodiment 2

[0035] The oxidant is hydrogen peroxide (commercially available, concentration 30%), 8mL is added to 300mL water, and shaken for 0.5h; the cleaning agent is hydrochloric acid (commercially available, concentration 37%) 5mL + calcium chloride (commercially available 6.6g, shaken for 1h; solid-liquid After separation, add a pH regulator to the cleaning solution (240mL), choose sodium hydroxide (10mol / L, 6.7mL) to adjust the pH value to 8-9, choose polyaluminum chloride PAC (commercially available) 15mg as the flocculant, place.

Embodiment 3

[0037] The oxidant is hydrogen peroxide (commercially available, concentration 30%), 5mL is added to 300mL water, and shaken for 0.5h; the cleaning agent is sulfuric acid (commercially available, concentration 98%) 2mL + ferric chloride (commercially available) 2.5g, shaken for 1h; After liquid separation, add pH regulator sodium hydroxide (10mol / L, 7mL) into the cleaning solution (245mL) to adjust the pH value to 8-9, choose PAM (commercially available) 1.5mg as flocculant, and let stand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com