Palladium nanoparticles and preparation method thereof

A technology of palladium nanoparticles and palladium salts, applied in the field of nanomaterials, can solve the problems of lack of industrial production potential, uncontrollable morphology of palladium nanoparticles, many reaction parameters, etc., and achieves low cost of raw materials, controllable morphology, High catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of palladium nanoparticles, comprising the following steps:

[0044] (1) Prepare K with a concentration of 1mol / L respectively 2 PdCl 4 Aqueous solution, 1mol / L cetyltrimethylammonium bromide aqueous solution and 100mmol / L ascorbic acid aqueous solution;

[0045] (2) Add 0.1mL of K 2 PdCl 4The aqueous solution was mixed with 0.2 mL of cetyltrimethylammonium bromide aqueous solution, and then 4.7 mL of ascorbic acid aqueous solution was added during stirring to obtain a mixed solution, and the mixed solution was stirred and reacted at 30° C. for 5 hours to obtain a reaction solution;

[0046] (3) Centrifuge the reaction solution in step (2) at 1000 RMP for 10 min. After the centrifugation, remove the supernatant to obtain a precipitate, wash the precipitate with water several times, and obtain palladium nanoparticles after washing.

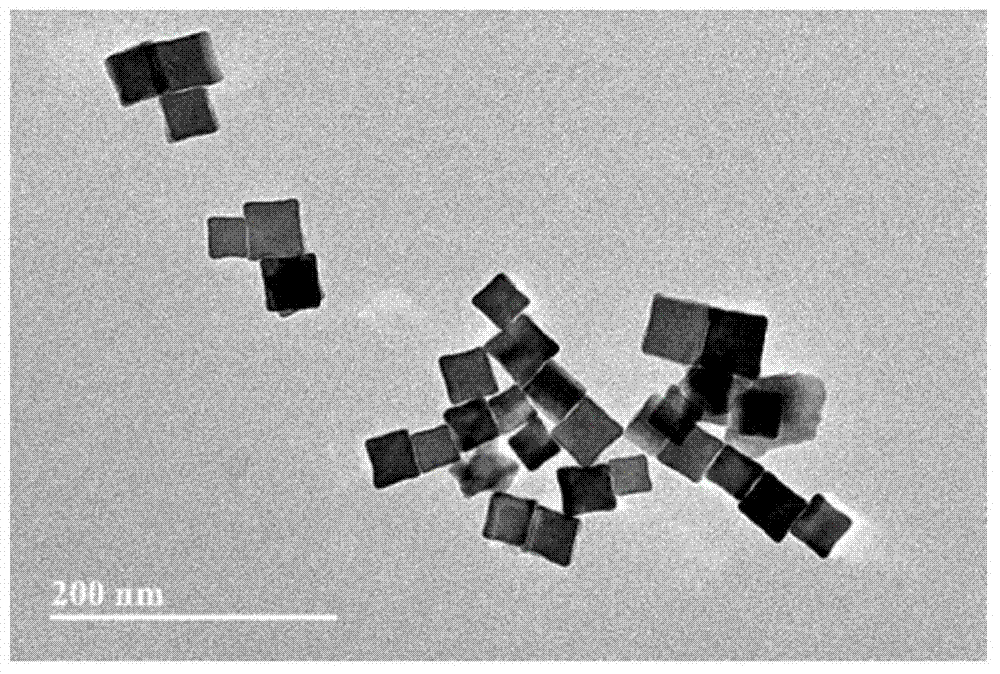

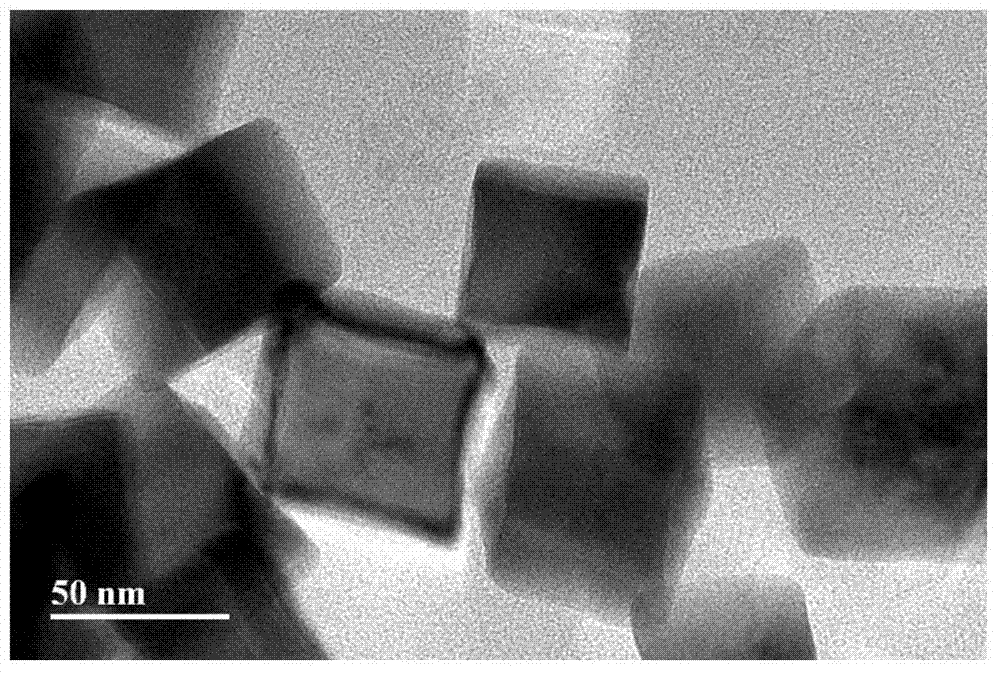

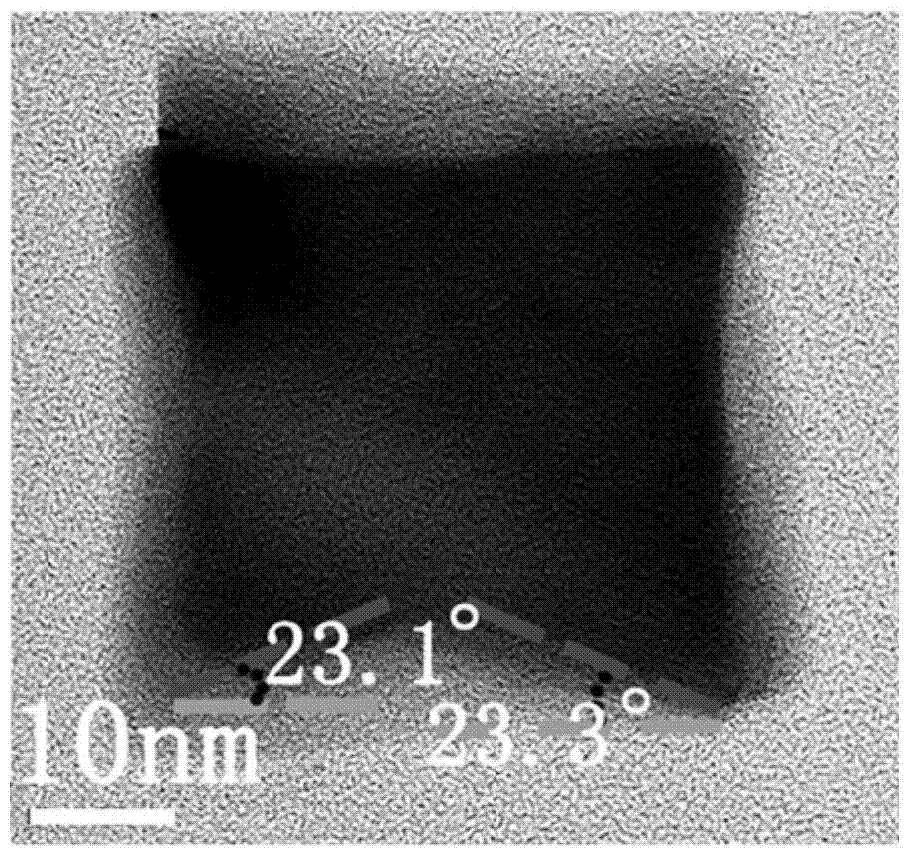

[0047] figure 1 It is the TEM figure of the palladium nanoparticle that embodiment 1 makes, and scale bar is 200n...

Embodiment 2

[0050] A preparation method of palladium nanoparticles, comprising the following steps:

[0051] (1) Prepare Na with a concentration of 1mol / L respectively 2 PdCl 4 aqueous solution, 1mol / L cetyltrimethylammonium chloride aqueous solution containing potassium bromide and 1mol / L formaldehyde solution; wherein, the concentration of Br in the cetyltrimethylammonium chloride aqueous solution containing potassium bromide is 1mol / L L, the concentration of cetyltrimethylammonium chloride is 1mol / L;

[0052] (2) Add 5mL of Na 2 PdCl 4 The aqueous solution was mixed with 10 mL of cetyltrimethylammonium chloride aqueous solution containing potassium bromide, and then 100 mL of formaldehyde aqueous solution was added to obtain a mixed solution during stirring, and the mixed solution was stirred and reacted at 90° C. for 12 hours to obtain a reaction liquid;

[0053] (3) Centrifuge the reaction solution in step (2) at 15000 RMP for 5 min. After the centrifugation, remove the supernata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com