A claw pole of an automobile generator and its manufacturing process

A technology of automobile generator and manufacturing process, which is applied in the direction of manufacturing tools, manufacturing motor generators, electromechanical devices, etc., can solve the technical requirements that the wall thickness of magnetic bars cannot be uniform, it is difficult to have uniform wall thickness of magnetic bars, and the effect of fixing magnets Poor and other problems, to achieve the effect of good product consistency, uniform wall thickness and consistent size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

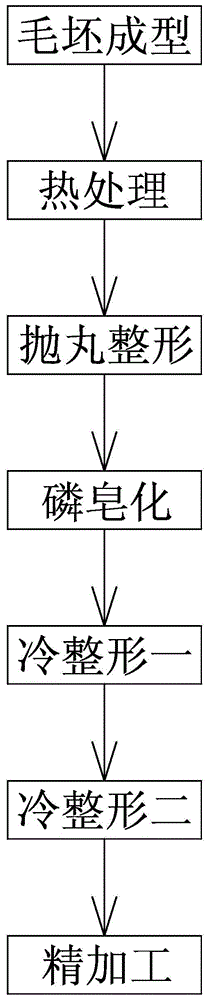

[0054] Such as figure 1 As shown, the manufacturing process of the claw pole of the automobile generator includes the following steps:

[0055] a. Blank forming: use a shearing machine to cut the bar, heat the sheared bar to 1160-1240°C with an intermediate frequency furnace, use a die forging machine to forge the heated bar to form a blank, and use a press to shape the blank flash cut off;

[0056] b. Heat treatment: Use a mesh belt furnace to heat treat the blank, so that the hardness of the blank is 90-160HV5, and the grain size is 6-8;

[0057] c. Shot blasting and shaping: Use a shot blasting machine to remove the scale on the surface of the heat-treated blank, and then use a hydraulic oil press to shape the blank;

[0058] d. Phosphorus saponification: Phosphorus saponification is carried out on the blank after shaping, so that the surface of the blank has a phosphorus saponification layer;

[0059] e. Cold shaping one: put the blank that has been saponified by phosph...

Embodiment 2

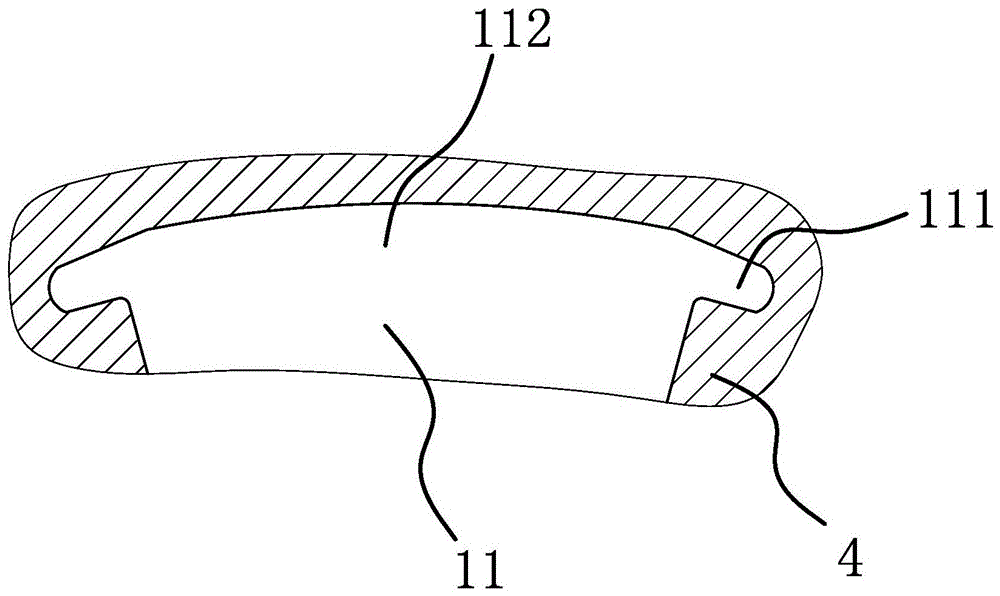

[0068] like Figure 11 As shown, the process flow and structure of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, four drainage grooves 16 and two positioning key grooves are evenly distributed on the circumferential edge of the yoke 10 18. Two positioning key grooves 18 are arranged symmetrically around the bottom plate 5. The positioning key grooves 18 are used to facilitate the positioning of the claw pole 20 during finishing. The drainage groove 16 is connected to the arc groove 15 through the lead-out wire groove 17 or the positioning key groove 18 , and there is no coil anti-rotation protrusion 19 in the structure of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com