A kind of ultra-high temperature thermal insulation composite material and preparation method thereof

A composite material, ultra-high temperature technology, applied in chemical instruments and methods, protective equipment, other household appliances, etc., can solve the problem of limited impact resistance of aerogel composite materials, temperature resistance not exceeding 1000 ° C, and inability to meet thermal protection. Demand and other issues, to achieve great application value, improve the bonding force between layers, and improve the effect of anti-vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

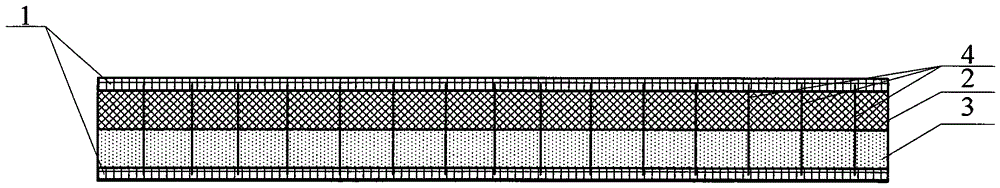

Image

Examples

Embodiment 1

[0056] Preparation of ultra-high temperature thermal insulation composite materials with a temperature resistance of 1600 °C.

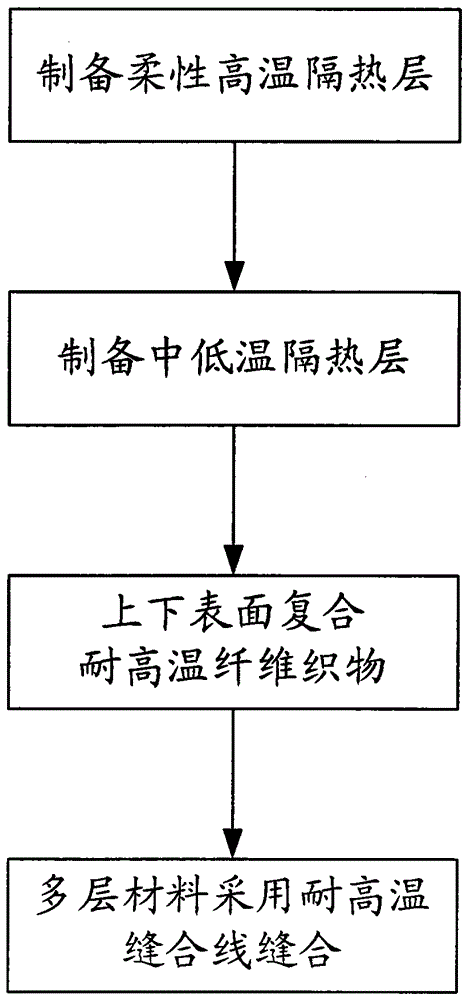

[0057] The specific preparation process is as figure 2 shown in the following steps:

[0058] (1) Preparation of flexible high temperature insulation layer

[0059] Zirconia fiber, silicon carbide infrared blocking agent, and polyvinyl alcohol-coated zirconium sol are used as a dispersant (polyvinyl alcohol accounts for 5% by mass of the solid part of the zirconium sol, and the pH value of the solution is 3).

[0060] Proportion: the addition of silicon carbide infrared blocking agent is 20% of the weight of alumina fiber or zirconia fiber, and the dispersant accounts for 100% of the weight of alumina fiber or zirconia fiber;

[0061] After mixing and dispersing the zirconia fiber, silicon carbide infrared blocking agent and dispersant evenly, the dispersant is removed and dried to obtain a flexible high-temperature heat insulation layer with a thi...

Embodiment 2~10

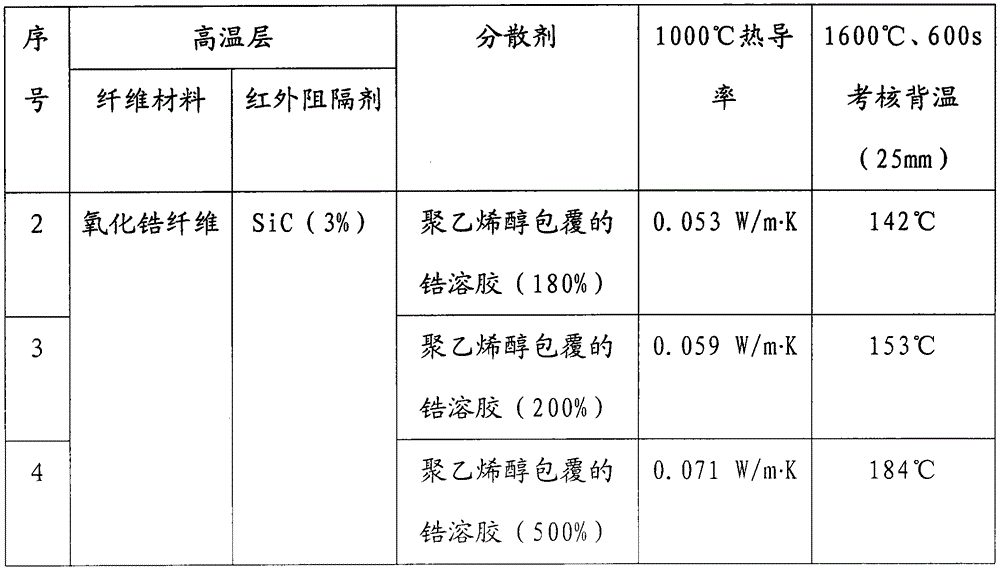

[0067] The ratio is shown in Table 1, and all the other are the same as Example 1, and the performance is shown in Table 1.

[0068] Table 1

[0069]

[0070]

Embodiment 11

[0072] Preparation of ultra-high temperature thermal insulation composite materials with a temperature resistance of 1400 °C.

[0073] The specific preparation process is the same as in Example 1.

[0074] Flexible high-temperature insulation layer: alumina fiber, zirconia fiber or mullite fiber, silicon carbide infrared barrier, polyvinyl alcohol-coated aluminum sol as a dispersant (polyvinyl alcohol accounts for 10% of the mass of aluminum sol solids, The pH value of the solution is 2).

[0075] Proportion: the addition of silicon carbide infrared blocking agent is 20% of the weight of alumina fiber or zirconia fiber, the dispersant is 130% of the weight of alumina fiber or zirconia fiber, and a flexible high-temperature heat insulation layer of 5mm is prepared .

[0076] The medium and low temperature insulation layer is made of mullite fiber reinforced silica airgel material, mullite fiber fabric is used for the high temperature side, mullite, quartz, aluminum silicate f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com