Method and system for jointly treating refinery gas by adopting membrane separation and pressure swing adsorption

A pressure swing adsorption and combined treatment technology, applied in the direction of using solid contact hydrogen separation, hydrogen separation, etc., can solve the problems of insufficient hydrogen treatment capacity, complicated control steps, low hydrogen purity, etc., to improve the hydrogen recovery effect and solve the problem of hydrogen source. Stressful, high hydrogen purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

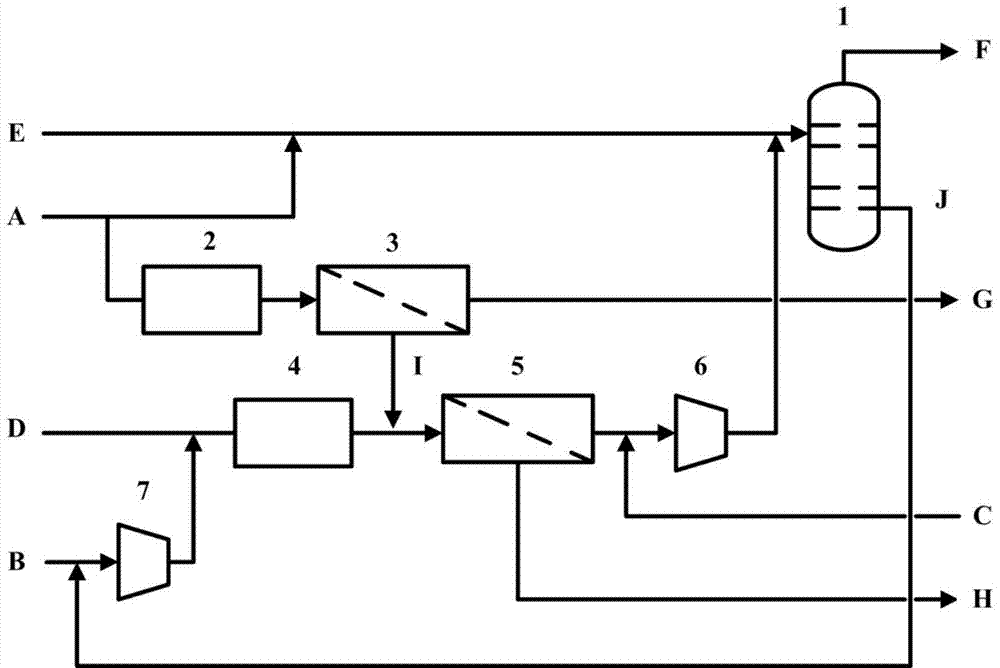

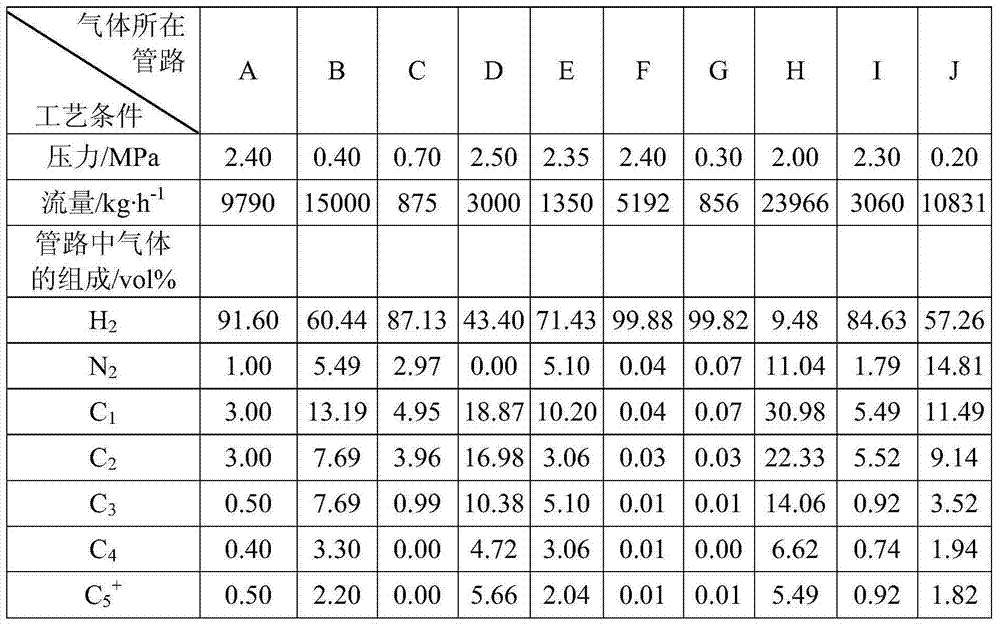

[0040] This example provides a system for combined treatment of refinery gas using membrane separation and pressure swing adsorption, the schematic diagram of which is shown in figure 1 As shown, the system includes:

[0041]Pressure swing adsorption device 1, first pretreatment device 2, first membrane separation device 3, second pretreatment device 4, second membrane separation device 5, first compressor 6, second compressor 7, reformed hydrogen pipe Road A, low-pressure hydrogen-poor gas pipeline B, low-pressure hydrogen-rich gas pipeline C, high-pressure hydrogen-poor gas pipeline D, high-pressure hydrogen-rich gas pipeline E, hydrogen outlet pipeline F of pressure swing adsorption device 1, the first membrane The hydrogen outlet pipeline G of the separation device 3, the retentate gas pipeline H of the second membrane separation device 5, the retentate gas pipeline I of the first membrane separation device 3, and the analytical gas pipeline J of the pressure swing adsorpt...

Embodiment 2

[0046] This embodiment provides a method for processing refinery gas using the system of Embodiment 1. According to the different requirements of the membrane separation device and the pressure swing adsorption device of Embodiment 1 on the composition and pressure of the feed gas, multiple streams of hydrogen-containing gas are divided into into five categories:

[0047] (1) reforming hydrogen, the pressure is 2.4MPa, the hydrogen concentration is 91.60vol%, it is divided into two shares, one is 40% of the reformed hydrogen total amount, and the other is 60%;

[0048] (2) Low-pressure hydrogen-poor gas with a pressure of 0.4MPa and a hydrogen concentration of 60.44vol%;

[0049] (3) Low-pressure hydrogen-rich gas with a pressure of 0.7MPa and a hydrogen concentration of 87.13vol%;

[0050] (4) High-pressure hydrogen-poor gas, the pressure is 2.5MPa, and the hydrogen concentration is 43.40vol%;

[0051] (5) High-pressure hydrogen-rich gas with a pressure of 2.35MPa and a hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com