Refining and purifying method for industrial silicon

A technology for refining and purifying industrial silicon, which is applied in the fields of chemical instruments and methods, silicon compounds, inorganic chemistry, etc. It can solve problems such as complex process, no obvious effect of difficult-to-volatile impurity elements, pollution, etc., and achieve high purification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

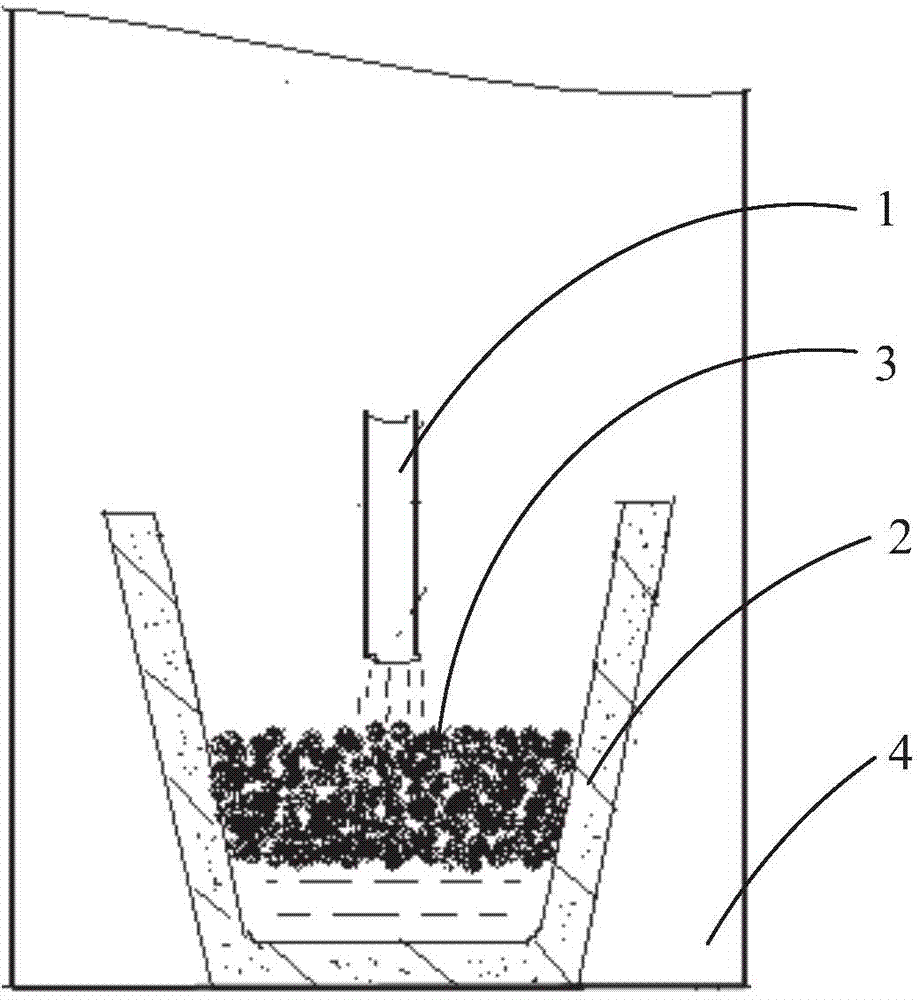

[0023] According to the above-mentioned technical solution of the present invention, the industrial silicon refining and purification method provided in this embodiment includes: figure 1 As shown, in the vacuum electric arc furnace 4, the industrial silicon rod 1 is used as the consumable cathode, and the crucible 2 containing the refining slag 3 is used as the anode. -4 ~10 - 2 Under the vacuum degree of Pa, the industrial silicon rod 1 is gradually melted and dropped onto the refining slag 3 from the lower end, and the C, O, H gas impurities and B, P volatile impurity elements in the industrial silicon molten droplets are volatilized and released, and then The vacuuming device is drawn out of the vacuum electric arc furnace 4 . After the industrial silicon drops onto the refining slag 3, non-volatile Fe, Ca, Ti, Al, V, and Na impurities enter the refining slag 3 through the slag-gold reaction and element exchange. When the industrial silicon rod 1 cathode melting is compl...

Embodiment 2

[0025] The difference between the present embodiment and the first embodiment is that in the present embodiment, the vacuum degree of the vacuum electric arc furnace is 10 -3 ~10 - 2 Pa, temperature is 1600 ~ 1700 ℃. The industrial silicon rods are produced by pressing and sintering industrial silicon crumbs and are refined in a vacuum consumable electric arc furnace with conventional diameters. The initial purity is that the Si content is not less than 99.5%. In the composition of said refining slag, calculated by mass percentage: SiO 2 30-50%, SiC 5-15%, Si 1-10%, MgO 0.1-0.5%, Al 2 o 3 15-25% for CaO, 15-25% for CaO, 0.1-0.5% for FeO, and the purity of silicon after refining reaches 5N.

Embodiment 3

[0027] According to the above-mentioned technical solution of the present invention, the industrial silicon refining and purification method provided in this embodiment includes: figure 1 As shown, in the vacuum electric arc furnace 4, the industrial silicon rod 1 is used as the consumable cathode, and the crucible 2 containing the refining slag 3 is used as the anode. -4 ~10 - 2 Under the condition of Pa vacuum degree, the industrial silicon rod 1 is gradually melted and dropped onto the refining slag 3 from the lower end, and the gas impurities and some volatile impurity elements in the industrial silicon molten drop are volatilized and released, and then the vacuum arc is drawn out by the vacuum device. Furnace 4 outside. After the industrial silicon drops onto the refining slag 3, non-volatile impurities enter the refining slag 3 through the slag-gold reaction and element exchange. After the industrial silicon rod 1 cathode melting is completed, the refining slag is remo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap