Method for extracting astaxanthin from fresh shrimp shell

A technology of astaxanthin and fresh shrimp shells, applied in the direction of organic chemistry, etc., can solve the problems of affecting the extraction rate of astaxanthin, producing waste acid and waste lye, and high cost, so as to achieve easy promotion and application, low cost, and improved The effect of extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

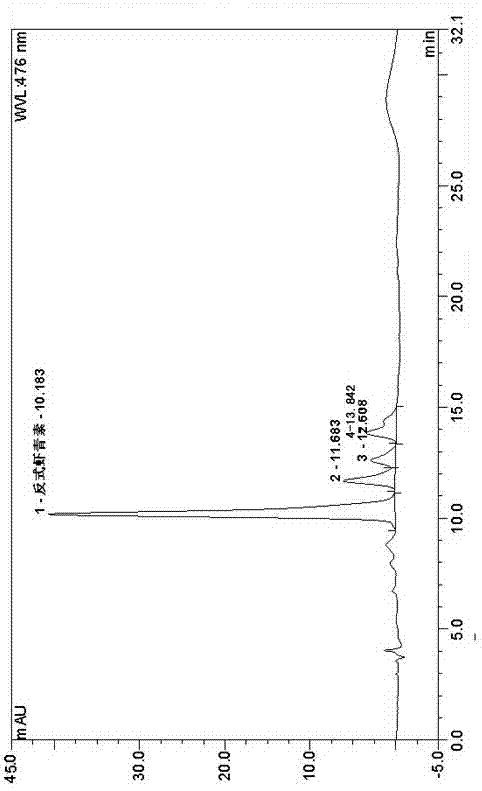

Image

Examples

Embodiment 1

[0024] (1) Take 25 g of fresh Penaeus chinensis shells and boil them in boiling water for 1 min, then remove and drain;

[0025] (2) After draining, put the shrimp shells in the refrigerator at -18℃ for 5 minutes, and immediately crush them with a plant grinder to obtain shrimp shell powder;

[0026] (3) Prepare the ethyl acetate-BHT extract with 250 mL ethyl acetate and 0.25 g 2,6-di-tert-butyl-4-methylphenol (BHT), place it in a stoppered Erlenmeyer flask, and add it to step (2) ) The crushed shrimp shell powder was extracted for 5 min under the auxiliary condition of ultrasonic power of 300 W to obtain the extract. The extract was concentrated under reduced pressure with a rotary evaporator (the temperature of the water bath of the rotary evaporator was 45℃) and then placed in- Temporarily store in the refrigerator at 18 ℃ to collect the shrimp shell residue after ultrasonic extraction;

[0027] (4) Put the shrimp shell residue collected in step (3) into a refrigerator at -18 ℃ f...

Embodiment 2

[0032] (1) Take 25 g of fresh Penaeus chinensis shells and boil them in boiling water for 5 minutes, then remove and drain;

[0033] (2) After draining, put the shrimp shells in the refrigerator at -18 ℃ for 10 minutes, and immediately crush them with a plant grinder after taking them out to obtain shrimp shell powder;

[0034] (3) Prepare the dichloromethane-BHT extract with 333 mL methanol, 167 mL dichloromethane and 0.5 g 2,6-di-tert-butyl-4-methylphenol (BHT) and place it in a stoppered Erlenmeyer flask, and Add the crushed shrimp shell powder in step (2), extract 15 min under the auxiliary condition of ultrasonic power of 400 W to obtain the extract, and use the rotary evaporator (the water bath temperature of the rotary evaporator is 45 ℃) to concentrate under reduced pressure Then put it in the refrigerator at -18 ℃, and collect the shrimp shell residue after ultrasonic extraction;

[0035] (4) Put the shrimp shell residues collected in step (3) in the refrigerator at -18 ℃ f...

Embodiment 3

[0040] (1) Take 25 g of fresh Penaeus chinensis shells and boil them in boiling water for 8 minutes, then remove and drain;

[0041] (2) After draining, put the shrimp shells in the refrigerator at -18℃ for 15 minutes, and immediately crush them with a plant grinder after taking them out to obtain shrimp shell powder;

[0042] (3) Prepare the dichloromethane-BHT extract with 750 mL of dichloromethane and 0.75 g of 2,6-di-tert-butyl-4-methylphenol (BHT), place it in a stoppered Erlenmeyer flask, and add it to step (2 ) The crushed shrimp shell powder was extracted for 25 min under the auxiliary conditions of 500 W power to obtain the extract. The extract was concentrated under reduced pressure with a rotary evaporator (the temperature of the water bath of the rotary evaporator was 45 ℃) and then placed at -18 Temporarily store in the refrigerator at ℃ to collect the shrimp shell residue after ultrasonic extraction;

[0043] (4) Freeze in a refrigerator at -18 ℃ for 2 h, then take it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com