Preparation process for fattening cream river crab compound feed

A technology of compound feed and production process, applied in the field of agricultural breeding, can solve the problems of short intestinal tract, water pollution, feed waste, etc., and achieve the effects of reducing diseases, improving water quality, and increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

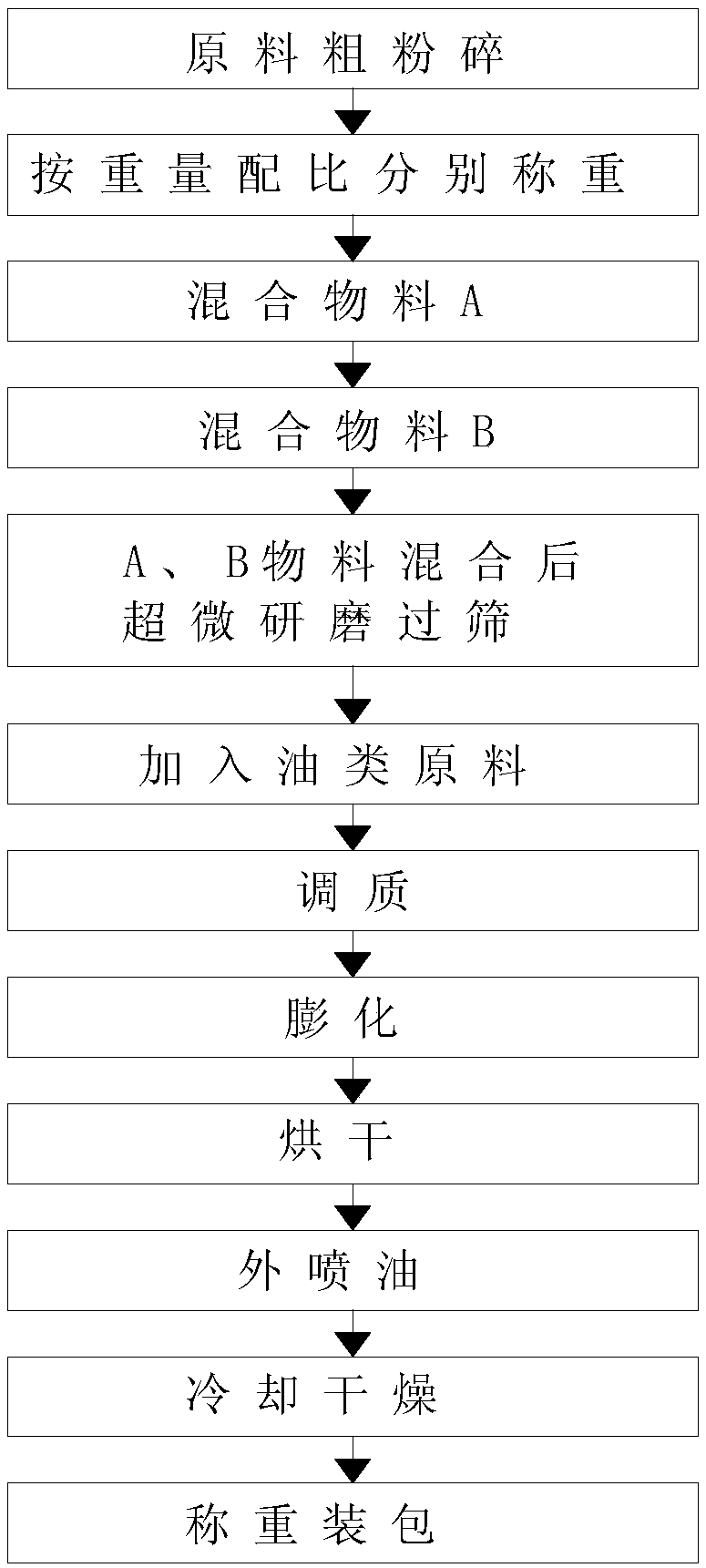

Image

Examples

Embodiment 1

[0047] Coarsely pulverize high-gluten flour, peeled and puffed soybean meal, fermented soybean meal, fish meal, chicken meal, shrimp powder, spirulina, and zeolite powder with a 2.0 sieve, and set aside; weigh 8 parts of high-gluten flour and 20 parts of peeled and puffed soybean meal , 4 parts of fermented soybean meal, 15 parts of fish meal, 10 parts of chicken meal, 3 parts of shrimp meal, 2 parts of squid paste, 2 parts of phospholipid oil, 1 part of soybean oil, 1 part of fish oil, 1 part of spirulina, 0.1 part of choline chloride, 1 part of zeolite powder, 1.5 parts of calcium dihydrogen phosphate, 0.4 parts of yeast hydrolyzate, 0.06 parts of crustacean multivitamins, 0.02 parts of compound organic trace elements, 0.02 parts of astaxanthin; Soybean meal, fermented soybean meal, fish meal, chicken meal, shrimp meal, spirulina, zeolite powder, squid paste, calcium dihydrogen phosphate are mixed and stirred evenly to obtain mixed material A, which is set aside; the specifie...

Embodiment 2

[0049] Coarsely pulverize high-gluten flour, peeled and puffed soybean meal, fermented soybean meal, fish meal, chicken meal, shrimp powder, spirulina, and zeolite powder with a 2.0 sieve, and set aside; weigh 9 parts of high-gluten flour and 22 parts of peeled and puffed soybean meal , 5 parts of fermented soybean meal, 17 parts of fish meal, 12 parts of chicken meal, 4 parts of shrimp meal, 3 parts of squid paste, 2.5 parts of phospholipid oil, 1.5 parts of soybean oil, 1.5 parts of fish oil, 1.5 parts of spirulina, 0.15 parts of choline chloride, 1.5 parts of zeolite powder, 1.7 parts of calcium dihydrogen phosphate, 0.55 parts of yeast hydrolyzate, 0.15 parts of crustacean multivitamins, 0.04 parts of compound organic trace elements, and 0.05 parts of astaxanthin; Soybean meal, fermented soybean meal, fish meal, chicken meal, shrimp meal, spirulina, zeolite powder, squid paste, calcium dihydrogen phosphate are mixed and stirred evenly to obtain mixed material A, which is se...

Embodiment 3

[0051] Coarsely pulverize high-gluten flour, peeled and puffed soybean meal, fermented soybean meal, fish meal, chicken meal, shrimp powder, spirulina, and zeolite powder with a 2.0 sieve, and set aside; weigh 10 parts of high-gluten flour and 25 parts of peeled and puffed soybean meal , 6 parts of fermented soybean meal, 20 parts of fish meal, 15 parts of chicken meal, 5 parts of shrimp meal, 4 parts of squid paste, 3 parts of phospholipid oil, 2 parts of soybean oil, 2 parts of fish oil, 2 parts of spirulina, 0.2 part of choline chloride, 2 parts of zeolite powder, 2.0 parts of calcium dihydrogen phosphate, 0.5 parts of table salt, 0.7 parts of yeast hydrolyzate, 0.06 parts of crustacean multivitamins, 0.02 parts of compound organic trace elements, and 0.02 parts of astaxanthin; , peeled and expanded soybean meal, fermented soybean meal, fish meal, chicken meal, shrimp meal, spirulina, zeolite powder, squid paste, calcium dihydrogen phosphate, mixed and stirred evenly to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com