Preparation method, secondary refining method and refining agent of PMHSS (powder metallurgy high speed steel)

A powder metallurgy and refining agent technology, applied in the refining agent for powder metallurgy high-speed steel out-of-furnace refining and the preparation of powder metallurgy high-speed steel, can solve unfavorable bottom pouring atomization process temperature control, weak deoxidation and desulfurization ability, and removal of inclusions Weak capacity, etc., to ensure the effect of removing inclusions, optimizing the slag resistance, and increasing the viscosity of the slag system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

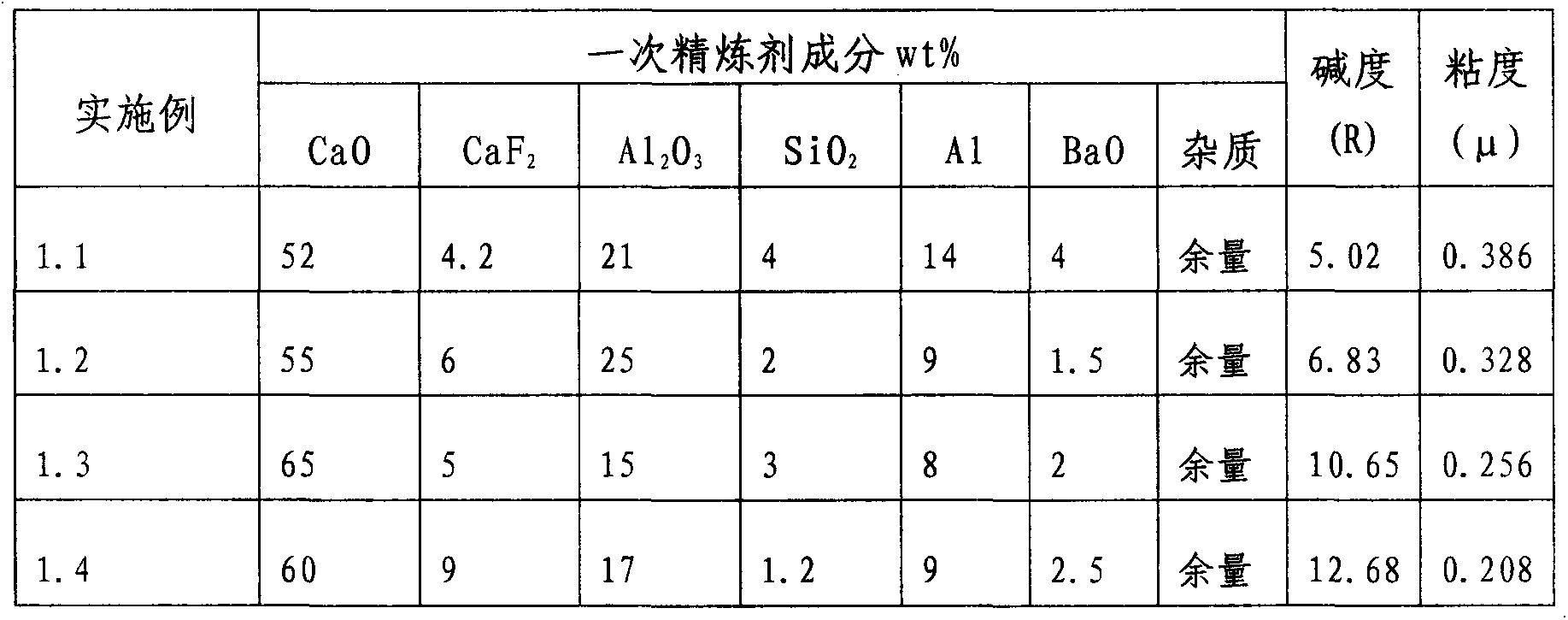

[0020] The following table lists the composition and content of the primary refining agent:

[0021]

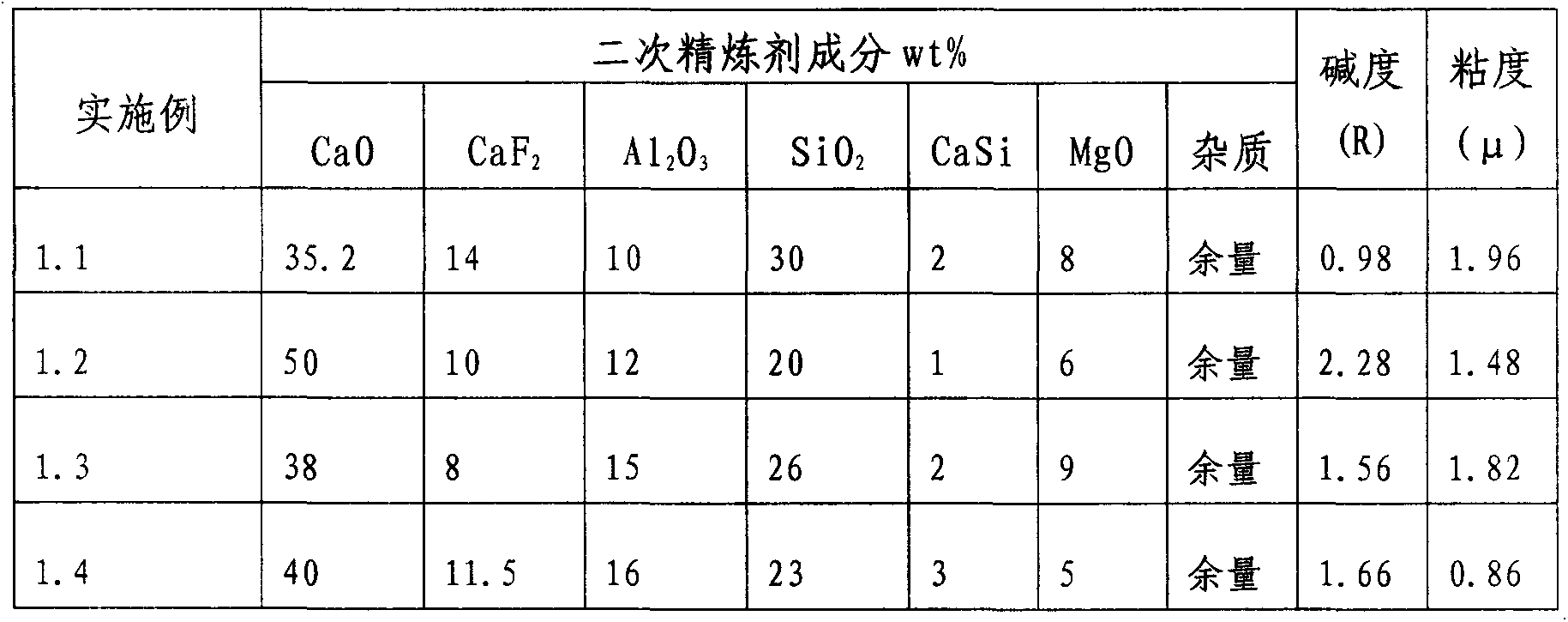

[0022] The following table lists the composition and content of the secondary refining agent:

[0023]

[0024] Note: The viscosity measurement temperature is 1600°C.

Embodiment 2

[0026] This embodiment relates to a powder metallurgy high-speed steel refining method outside the furnace. The primary refining agent and the secondary refining agent involved in this method all use the ingredients in Example 1, and for the convenience of illustrating the industrial implementation of the present invention, in In this embodiment, the raw materials containing the active ingredients in the first embodiment are selected, such as CaF 2 Adopt fluorite powder, MgO adopts dolomite etc., the detailed steps of this method are as follows:

[0027] Step 1, one-time refining, adding a refining agent to molten steel for one-time refining:

[0028] a. Prepare the baked tundish, and add the weighed limestone and fluorite powder to the bottom of the tundish;

[0029] b. Pour the molten steel formed by intermediate frequency smelting at a temperature of 1600-1680°C into the tundish;

[0030] c. From the tundish to the refining station, pass argon gas, the flow rate is 80-160...

Embodiment 3

[0039] This embodiment relates to a preparation method of powder metallurgy high-speed steel, which includes the steps of molten steel smelting, out-of-furnace refining, bottom pouring and atomization, powder sheathing, sealing welding and exhausting, hot isostatic pressing, and forging. , wherein the out-of-furnace refining adopts the method steps of Embodiment 2.

[0040] After the second step of the embodiment is completed, the bottom pouring atomization can be carried out. Specifically, after the temperature of the bottom pouring atomization is stabilized in the above steps, the flow rate of argon gas is controlled at 10-50L / min, and the atomization starts. At this time, the slag The slag resistance reaches a relatively stable state, and the atomization temperature can be controlled within the fluctuation range of 5°C, which not only provides a stable atomization effect, but also stabilizes the heat preservation of the molten steel and maintains the calmness of the molten s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com