Method for modifying polyether-ether-ketone surface

A polyetheretherketone modification technology, which is applied in the field of surface modification of biomedical polymer materials, can solve problems affecting the normal activities of cells, and achieve stable and controllable preparation processes, easy popularization and application, and good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] a) The medical PEEK material is washed three times with ethanol, acetone, and deionized water after polishing; b) The magnet is placed in concentrated sulfuric acid, stirred at a speed of 300r / min in a magnetic stirrer, and the PEEK is placed in Among them, react for 5 minutes, place the sulfonated PEEK in deionized water, soak for 5 minutes, take it out and dry it naturally to obtain a modified layer with a three-dimensional pore structure; c) place the sulfonated PEEK in deionized water at 80°C After hydrothermal treatment in a hydrothermal kettle for 24 hours, the sample was taken out, rinsed, and dried naturally to obtain a modified layer with a three-dimensional pore structure without S.

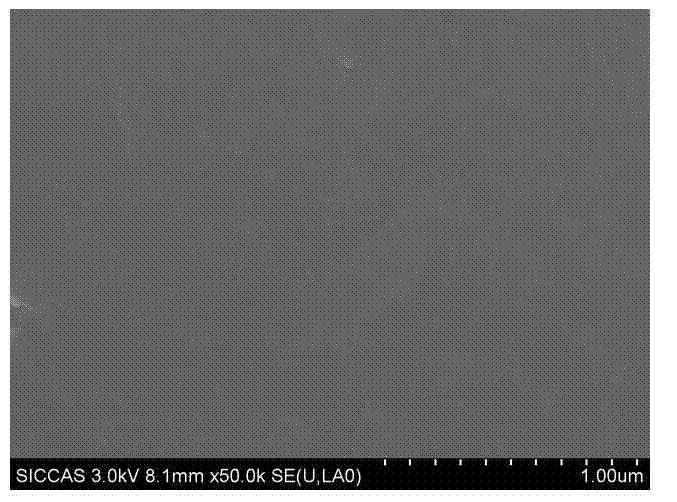

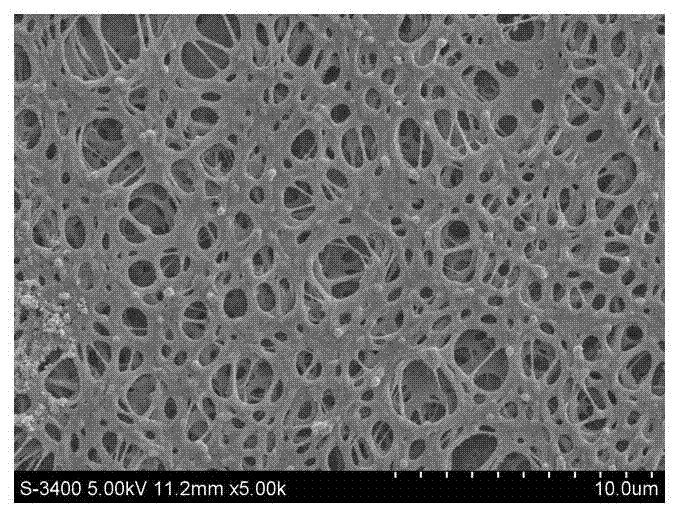

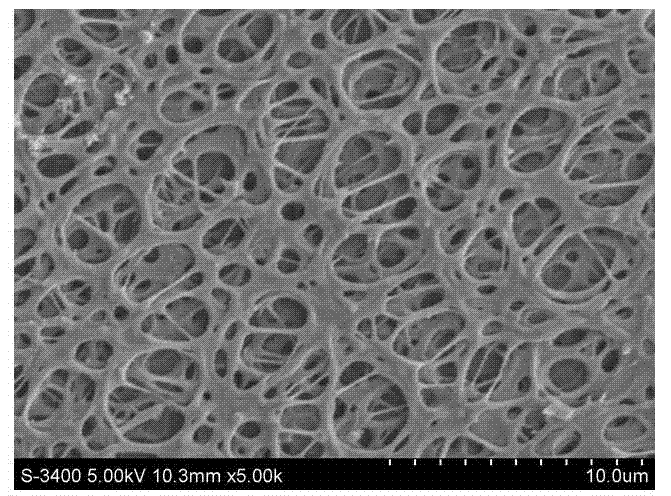

[0062] Fig. 1 (a), Fig. 1 (b), Fig. 1 (c) are related accompanying drawings in the embodiment; As can be seen from Fig. 1 (a), Fig. 1 (b), Fig. 1 (c), sulfonation The treatment can form a three-dimensional channel structure on the surface of PEEK, and the hydrothermal treatment w...

Embodiment 2

[0067] a) The medical PEEK material is washed three times with ethanol, acetone, and deionized water after polishing; b) The magnet is placed in concentrated sulfuric acid, stirred at a speed of 300r / min in a magnetic stirrer, and the PEEK is placed in Wherein reaction 5min, the PEEK after sulfonation is placed in deionized water, soaks 5min, takes out and dries naturally, obtains the modified layer with three-dimensional pore structure; After hydrothermal treatment in a hydrothermal kettle for 24 hours at ℃, the sample was taken out, rinsed, and dried naturally to obtain a modified layer with a three-dimensional pore structure without S;

[0068] Figure 2(c) is the EDS spectrum of the PEEK that has undergone vulcanization treatment and hydrothermal treatment in this example. It can be seen that most of the S in the three-dimensional pore structure can be removed by hydrothermal treatment with dilute hydrochloric acid as the hydrothermal medium at 80 °C. .

Embodiment 3

[0070] a) The medical PEEK material is washed three times with ethanol, acetone, and deionized water after polishing; b) The magnet is placed in concentrated sulfuric acid, stirred at a speed of 300r / min in a magnetic stirrer, and the PEEK is placed in Wherein react for 5min, place the PEEK after sulfonation in deionized water, soak for 5min, take out and dry naturally, obtain the modified layer with three-dimensional pore structure; c) place the PEEK after sulfonation in de-diluted sodium hydroxide After hydrothermal treatment in a hydrothermal kettle at 80°C for 24 hours, the sample was taken out, rinsed, and dried naturally to obtain a modified layer with a three-dimensional pore structure without S;

[0071] Figure 2(d) is the EDS spectrum of the PEEK that has undergone vulcanization treatment and hydrothermal treatment in this example. It can be seen from it that the hydrothermal treatment with dilute sodium hydroxide as the hydrothermal medium at 80°C can remove part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com