A kind of self-foaming foam drainage agent and preparation method thereof

A foam drainage agent and self-foaming technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of easy drowning, high cost, long time, etc., and achieve convenient preparation and low production cost. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

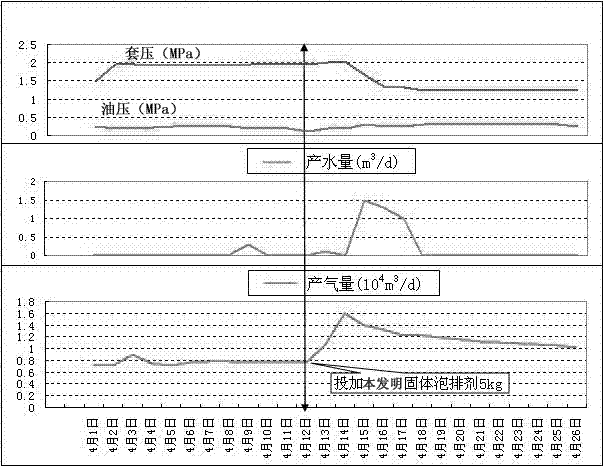

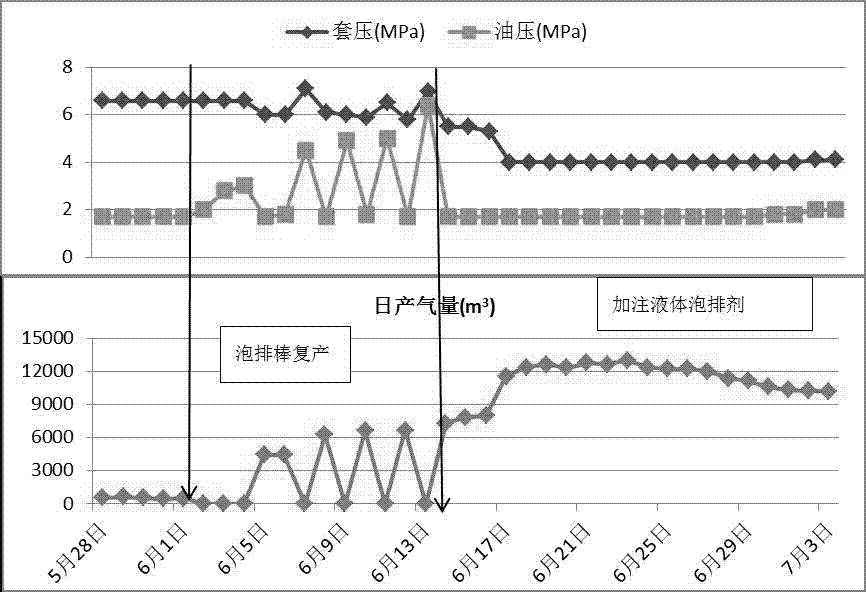

Image

Examples

Embodiment 1

[0029] Embodiment 1: A kind of self-foaming type foam draining agent, it is made up of the raw material of following parts by weight: Sapindus saponin: 20; Sodium fatty acid methyl ester sulfonate: 8; Hydroxy ethylene diphosphonic acid: 8; Sodium bicarbonate: 10; Tartaric acid: 10.

[0030] The preparation method of above-mentioned self-foaming type foam drainage agent, it may further comprise the steps:

[0031] S1. Weighing: Weigh each raw material according to the above ratio, and set aside;

[0032] S2. Drying: drying the weighed raw materials at a temperature of 100°C until the water content is 2%;

[0033] S3. Compression: Add the dried raw materials into a mixer, stir for 4 minutes, and then transfer to a hydraulic press to press into a round rod-shaped solid to obtain a self-foaming foam drainage agent.

Embodiment 2

[0034] Embodiment 2: A kind of self-foaming type foam drainage agent, it is made up of the raw material of following parts by weight: Sapindus saponin: 40; Sodium fatty acid methyl ester sulfonate: 25; Hydroxy ethylene diphosphonic acid: 25; Sodium bicarbonate: 30; Tartaric acid: 30.

[0035] The preparation method of above-mentioned self-foaming type foam drainage agent, it may further comprise the steps:

[0036] S1. Weighing: Weigh each raw material according to the above ratio, and set aside;

[0037] S2. Drying: drying the weighed raw materials at a temperature of 110°C until the water content is 1.3%;

[0038] S3. Compression: Add the dried raw materials into a mixer, stir for 8 minutes, and then transfer to a hydraulic press to press into a round rod-shaped solid to obtain a self-foaming foam drainage agent.

Embodiment 3

[0039] Embodiment 3: A kind of self-foaming type foam draining agent, it is made up of the raw material of following parts by weight: Sapindus saponin: 25; Sodium fatty acid methyl ester sulfonate: 10; Hydroxy ethylene diphosphonic acid: 10; Sodium bicarbonate: 18; tartaric acid: 18.

[0040] The preparation method of above-mentioned self-foaming type foam drainage agent, it may further comprise the steps:

[0041] S1. Weighing: Weigh each raw material according to the above ratio, and set aside;

[0042] S2. Drying: drying the weighed raw materials at a temperature of 102°C until the water content is 2.8%;

[0043] S3. Pressing: Add the dried raw materials into a mixer, stir for 5 minutes, and then transfer to a hydraulic press to press into a round rod-shaped solid, that is, a self-foaming foam drainage agent is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com