Method for preparing ethyl alcohol

A technology of ethanol and mash, applied in the direction of biofuels, fermentation, etc., can solve the problems of increased power consumption, difficult transportation of mash, and failure to reach it, so as to solve the problems of transportation difficulties, reduce energy consumption, and solve incomplete saccharification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

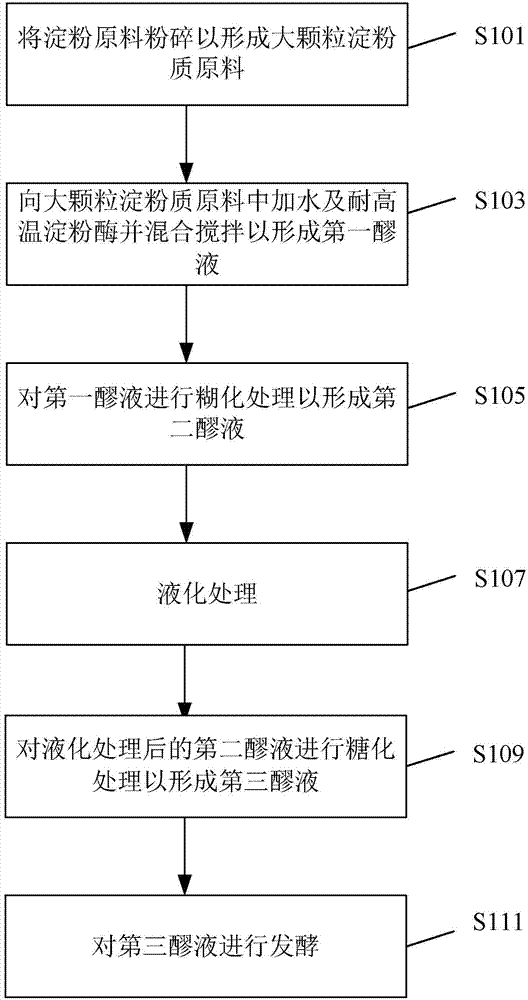

Method used

Image

Examples

Embodiment 1

[0032] 1. Raw material crushing: Cassava dry raw materials are sent from the silo to the raw material inlet of the pulverizer through a belt conveyor or a bucket elevator, and the sieve plate aperture of the pulverizer is selected to be 4mm. After crushing, the pulverized raw material powder is screened. The content of fine powder passing through the 1.2mm sieve accounted for 3.5% of the total raw material powder, the content of fine powder passing through the 3.0mm sieve accounted for 11.8% of the total raw material powder, and the content of large particles exceeding 3.5mm sieve accounted for the total raw material powder 1.5%, of which large particles with a particle size of 3.0mm to 3.5mm account for 86.7% of the total raw material powder; then the powder is sent to the silo for temporary storage.

[0033] 2. Crushing and mixing: use the recovered water from the distillation section, cool down to 75°C and then mix. The temperature after mixing needs to reach 65°C. Add high...

Embodiment 2

[0039] 1. Raw material crushing: If cassava dry raw material is sent from the silo to the raw material inlet of the pulverizer through the belt conveyor or bucket elevator, the aperture of the sieve plate of the pulverizer is 4mm, and the pulverized raw material powder is screened after crushing , the content of fine powder passing through the 1.2mm sieve accounted for 3.5% of the total raw material powder, the content of fine powder passing through the 3.0mm sieve accounted for 11.8% of the total raw material powder, and the content of large particles exceeding 3.5mm sieve accounted for the total raw material powder The amount is 1.5%, of which large particles with a particle size of 3.0mm to 3.5mm account for 86.7% of the total raw material powder; then the material powder is sent to the silo for temporary storage.

[0040] 2. Grinding and mixing materials: use the recovered water from the distillation section, and mix the materials after cooling down to 75 ° C. The temperatu...

Embodiment 3

[0046] 1. Raw material crushing: If cassava dry raw materials are sent from the silo to the raw material inlet of the pulverizer through a belt conveyor or bucket elevator, the aperture of the sieve plate of the pulverizer is 6mm, and the pulverized raw material powder is screened after crushing , the content of fine powder passing through the 1.2mm sieve accounted for 2.5% of the total raw material powder, the content of fine powder passing through the 3.0mm sieve accounted for 10.8% of the total raw material powder, and the content of large particles exceeding 3.5mm sieve accounted for the total raw material powder The amount is 2.0%, and the large particles with a particle size of 3.0-3.5mm account for 87.2% of the total raw material powder; then the material powder is sent to the silo for temporary storage.

[0047]2. Grinding and mixing materials: use the recovered water from the distillation section, and mix the materials after cooling down to 75 ° C. The temperature afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com